Support leveling steel plate position adjusting device and method for manufacturing precast beam

An adjustment device and leveling technology, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of high construction cost, easy to cause deviation, increase costs, etc., achieve flexible and controllable posture, and ensure adjustment accuracy , Adjust the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

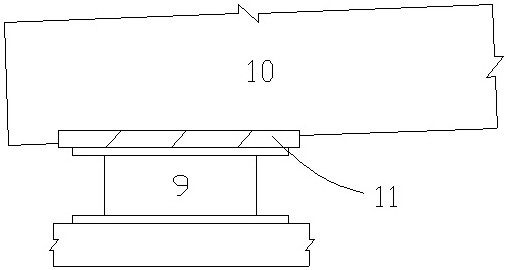

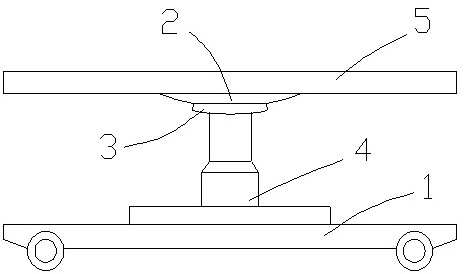

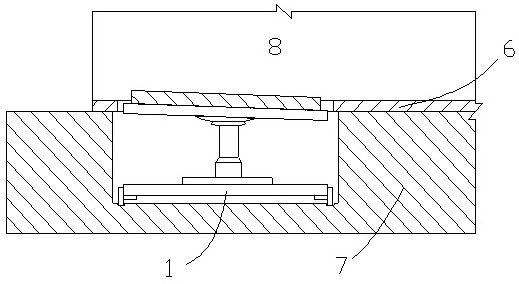

[0031] A support leveling steel plate position adjustment device, its structure is: the support leveling steel plate position adjustment device consists of a trolley 1, a magnetic levitation device, a lifting device 4, a support plate 5, a two-axis inclination sensor, a driving device and a control module composition;

[0032] The lifting device 4 is arranged on the upper end surface of the trolley 1;

[0033] The magnetic levitation device is composed of a floating body 2 and a base 3; the upper end of the floating body 2 is fixedly connected to the middle part of the lower end surface of the support plate 5, and the upper end surface of the support plate 5 is a plane; the lower end surface of the floating body 2 is convex. Spherical surface, the middle part of the lower end surface of the floating body 2 is provided with a plurality of positioning protrusions 2-1; the upper end surface of the base 3 is a concave spherical surface, and the upper end surface of the base 3 matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com