A modular waste gas treatment device

An exhaust gas treatment device and modular technology, which is applied in combination devices, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of single use, unsatisfactory purification effect, inconvenient replacement, etc. Equipment utilization, good effect of purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing of description, the present invention will be further described.

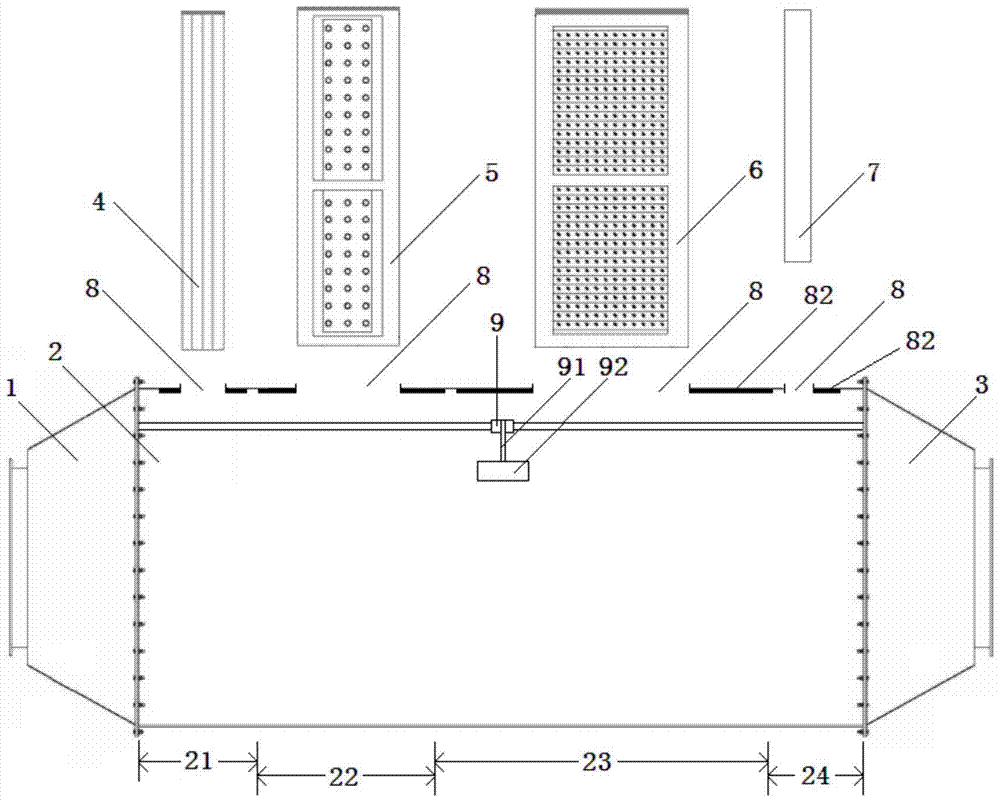

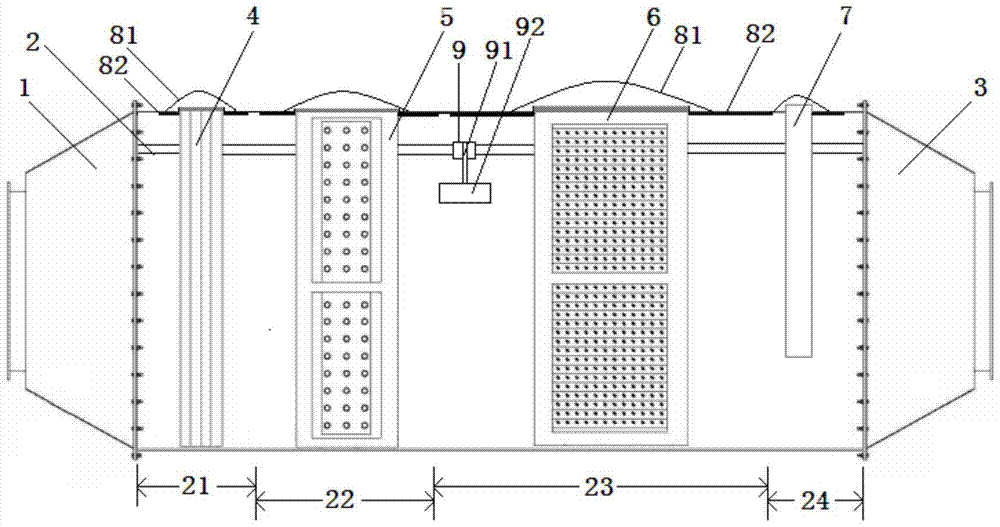

[0023] Such as figure 1 and figure 2 As shown, a modular exhaust gas treatment device includes an inlet pipe 1, a processing pipe 2, and an outlet pipe 3 connected in sequence; The coarse filter area 21 of group 4 is provided with the fine filter area 22 of at least one fine filter module 5, is provided with the special treatment area 23 of at least one special treatment module 6, and is provided with at least one detection module 7 before the air outlet Detection zone 24.

[0024] The top pipe wall of the processing tube 2 where the coarse filter area 21, the fine filter area 22, the special treatment area 23 and the pre-outlet detection area 24 are all provided with at least one assembly window 8, the coarse filter module 4, the fine filter module The filter module 5, the special treatment module 6 and the detection module 7 are all installed in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com