a single phase gd 2 co 7 Type rare earth magnesium-nickel hydrogen storage alloy, preparation method and application thereof

A technology of hydrogen storage alloy and rare earth magnesium, which is applied in the field of new energy materials, can solve the problems of low discharge capacity of hydrogen storage alloy, complex phase transition reaction of the alloy, and unreported preparation methods, etc., achieve excellent electrochemical discharge capacity, reduce heat Effect of uneven deformation and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

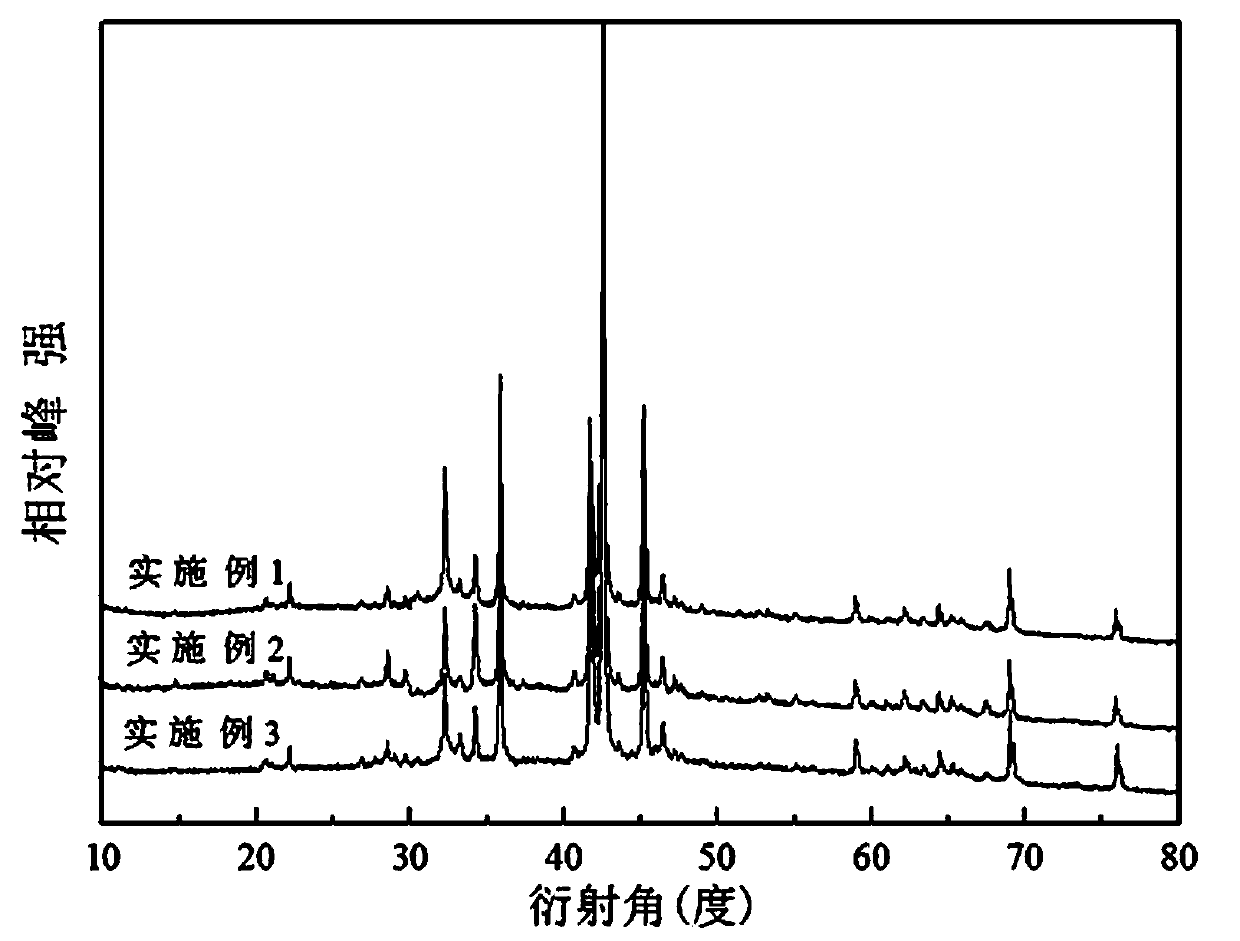

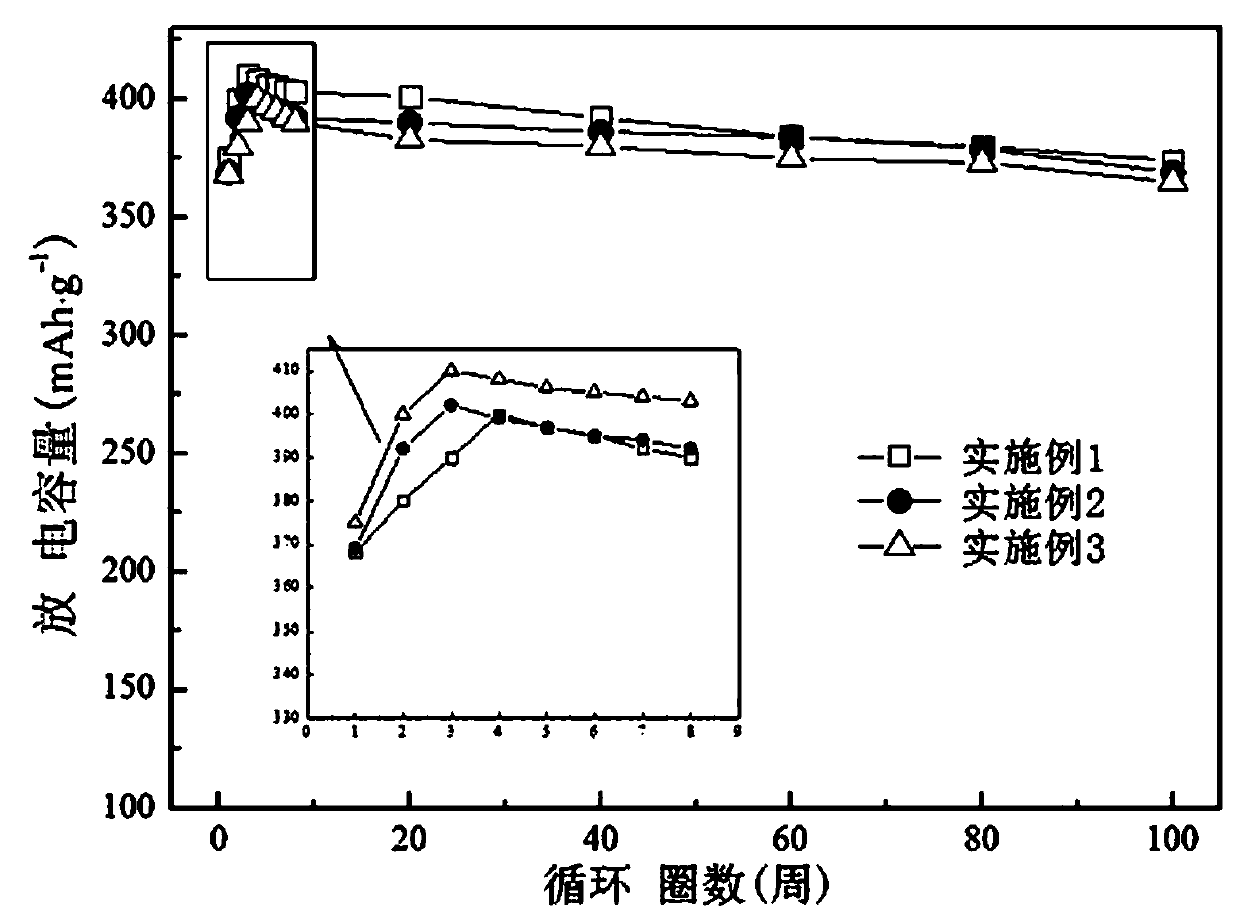

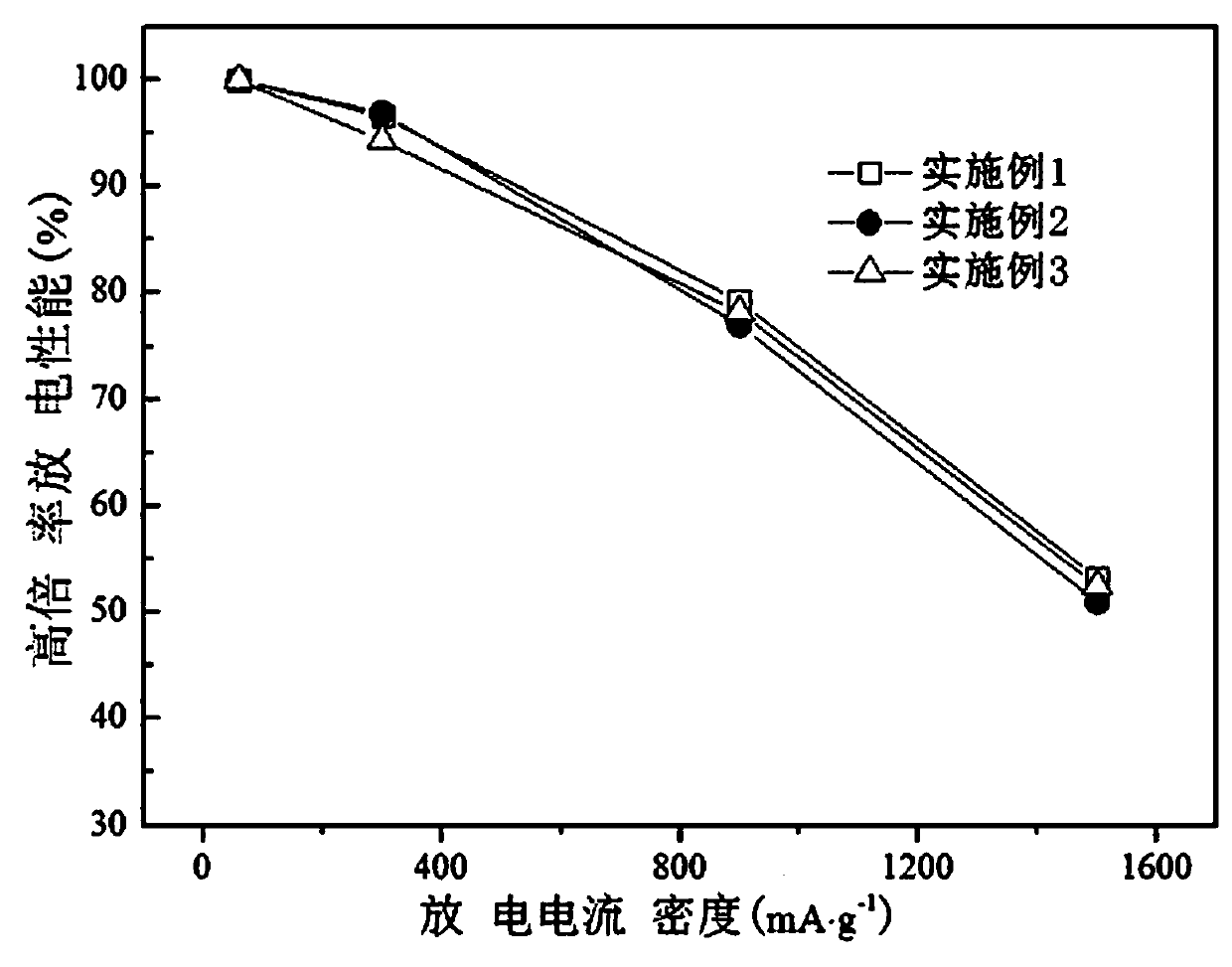

[0043] Example 1 A single-phase Gd 2 co 7 Type rare earth magnesium-nickel hydrogen storage alloy and preparation method thereof

[0044] This embodiment prepares La 0.70 SM 0.15 Mg 0.15 Ni 3.30 al 0.15 Hydrogen storage alloy, the specific preparation steps are as follows:

[0045] (11) Induction melting

[0046] Select metal elemental La, Sm, Mg, Ni, Al as raw materials, according to the alloy composition La 0.70 SM 0.15 Mg 0.15 Ni 3.30 al 0.15 Carry out batching, supplement and increase according to the volatilization amount of corresponding element during batching, and then adopt conventional induction melting method to prepare as-cast alloy, denote as a1;

[0047] (12) Annealing treatment

[0048] Take a1 and place it in a vacuum annealing furnace. After sealing, the vacuum degree is 5×10 -3 Annealing treatment is carried out under Pa vacuum environment. The annealing process adopts a five-stage heating process. The specific annealing procedure is as follows:...

Embodiment 2

[0060] Example 2 A single-phase Gd 2 co 7 Type rare earth magnesium-nickel hydrogen storage alloy and preparation method thereof

[0061] This embodiment prepares La 0.65 SM 0.10 Nd 0.05 Mg 0.20 Ni 3.35 mn 0.05 Hydrogen storage alloy, the specific preparation steps are as follows:

[0062] (21) Induction melting

[0063] Select metal elemental La, Sm, Nd, Mg, Ni, Mn as raw materials, according to the alloy composition La 0.65 SM 0.10 Nd 0.05 Mg 0.20 Ni 3.35 mn 0.05 Carry out batching, supplement and increase according to the volatilization of corresponding element during batching, then adopt conventional induction melting method to prepare cast alloy, denote as a2;

[0064] (22) Annealing treatment

[0065] Take a2 and place it in a vacuum annealing furnace. After sealing, the vacuum degree is 5×10 -2 Annealing treatment is carried out under Pa vacuum environment. The annealing treatment is a five-stage heating process. The annealing procedure is as follows: ...

Embodiment 3

[0077] Example 3 A single-phase Gd 2 co 7 Type rare earth magnesium-nickel hydrogen storage alloy and preparation method thereof

[0078] This embodiment prepares La 0.65 SM 0.10 Y 0.05 Mg 0.20 Ni 3.20 al 0.20 Hydrogen storage alloy, the specific preparation steps are as follows:

[0079] (31) induction melting

[0080] Select metal elemental La, Sm, Y, Mg, Ni, Al as raw materials, according to the alloy composition La 0.65 SM 0.10 Y 0.05 Mg 0.20 Ni 3.2 0 al 0.20 Carry out batching, supplement and increase according to the volatilization of corresponding element during batching, then adopt conventional induction melting method to prepare cast alloy, denote as a3;

[0081] (32) Annealing treatment

[0082] Take a3 and place it in a vacuum annealing furnace. After sealing, the vacuum degree is 5×10 -4 Annealing is carried out under Pa vacuum environment, and described annealing program is as follows:

[0083] The first heating stage: from room temperature to 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com