Vacuum acid filling device for AGM battery

A vacuum and acid filling technology, which is applied in the direction of secondary batteries, lead-acid batteries, battery pack components, etc., can solve the problems of acid filling error, inability to perform vacuum operation, and inability to weigh the battery acid filling volume, etc., to achieve The effect of accurate weighing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

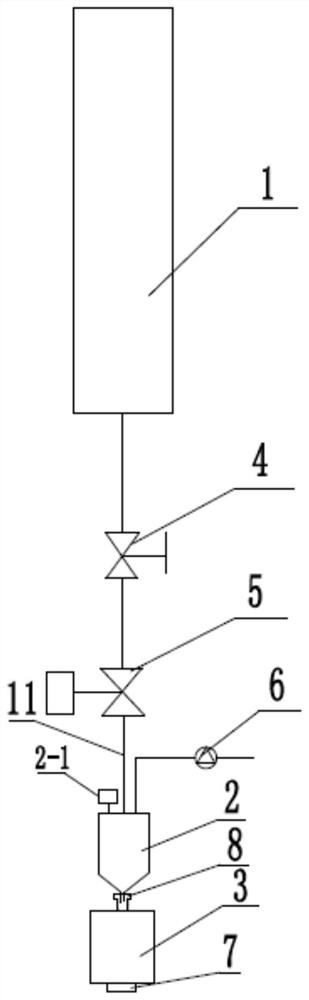

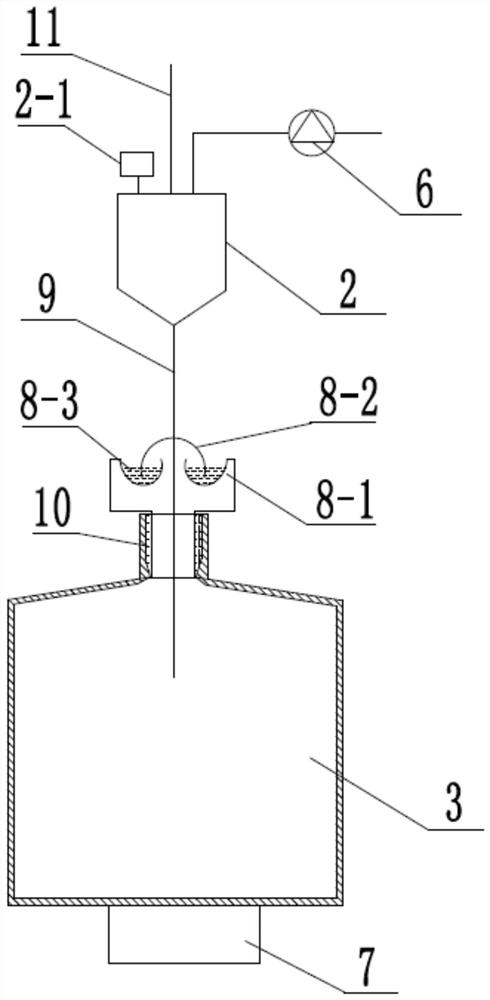

[0018] see figure 1 , a vacuum acid filling device for AGM batteries, the system includes an acid storage container 1, a confluence 2 and an acid measurement container 3, the top of the confluence 2 is connected to the acid storage container 1 through a flow pipe 11, and the flow The pipeline 11 is provided with an on-off valve 4 and a regulating valve 5 sequentially from top to bottom. The regulating valve continuously adjusts its opening through the control circuit, and finally locks the opening of the regulating valve, so that the actual amount of acid injected within a certain period of time is the same as that of the regulating valve. The amount of theoretical injection of acid is controlled within the error range. The outlet at the bottom of the confluence 2 is connected to the acid injection hole on the top of the acid measuring container 3 through the perfusion pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com