Method for determining backfilling rate of regenerated cut stem product

A measurement method and product technology, applied in the direction of weighing by removing certain components, can solve the problem that reconstituted cut stems cannot accurately reflect the backfill rate, cannot measure the backfill rate of reconstituted cut stem products, and cannot measure the weight of cut stems that have been backfilled. Determination and other issues, to achieve the results of true and reliable measurement results, good economy and practicability, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

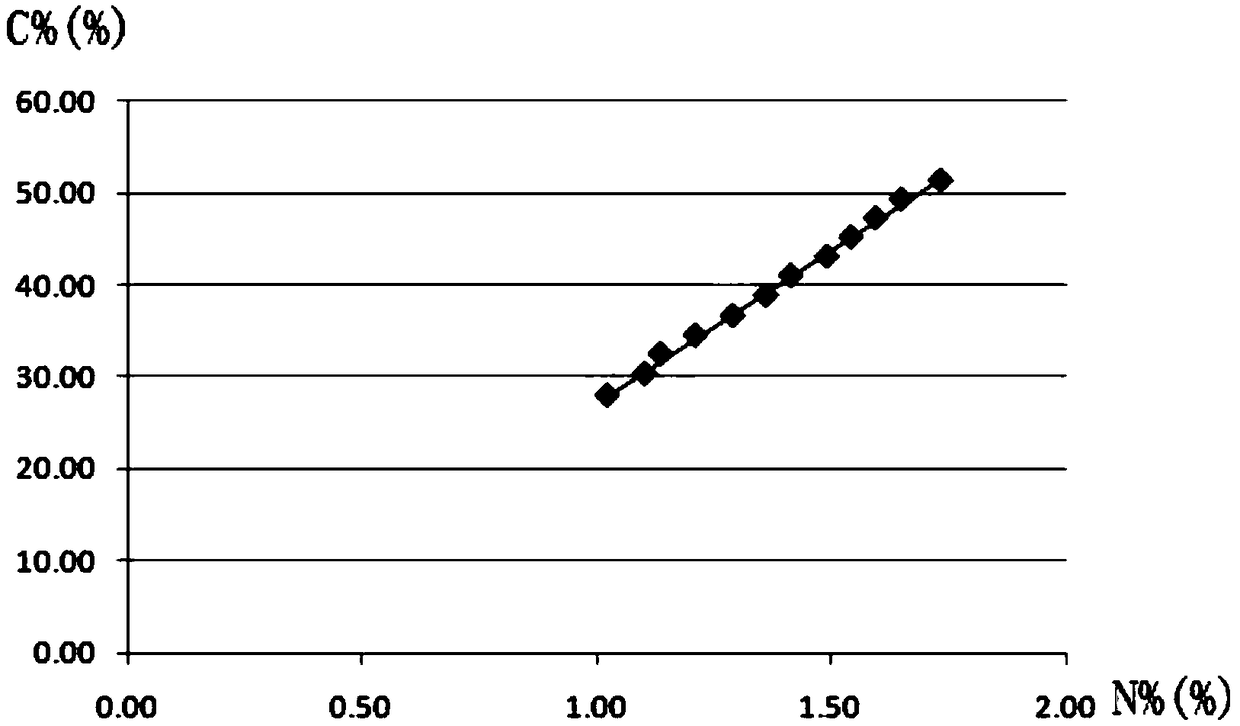

Embodiment 1

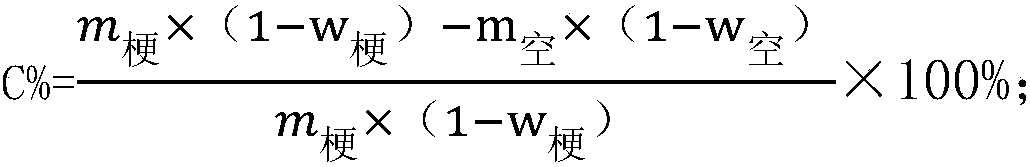

[0037] A method for determining the backfill rate of reconstituted shredded stem products, comprising the following steps:

[0038] (1) Use electronic weighing equipment to weigh the mass of No. 1 formula as m 空 of blank reconstituted stems, with a mass of m 液 The reconstituted cut stems backfill liquid, and evenly backfill it into the blank reconstituted cut stems, if necessary, the backfill liquid can be diluted with water;

[0039] The electronic weighing equipment in the step (1) is an electronic balance, which is easy to operate and accurate in weighing results;

[0040] (2) After standing still for 5 minutes, dry the reconstituted shredded stems after backfilling with drying equipment;

[0041] The drying equipment in the step (2) is an oven, which has the advantages of good drying effect and high work efficiency;

[0042] (3) After the drying is completed, the sample is placed in a constant temperature and humidity box, and after 24 hours of equilibrium, the finished...

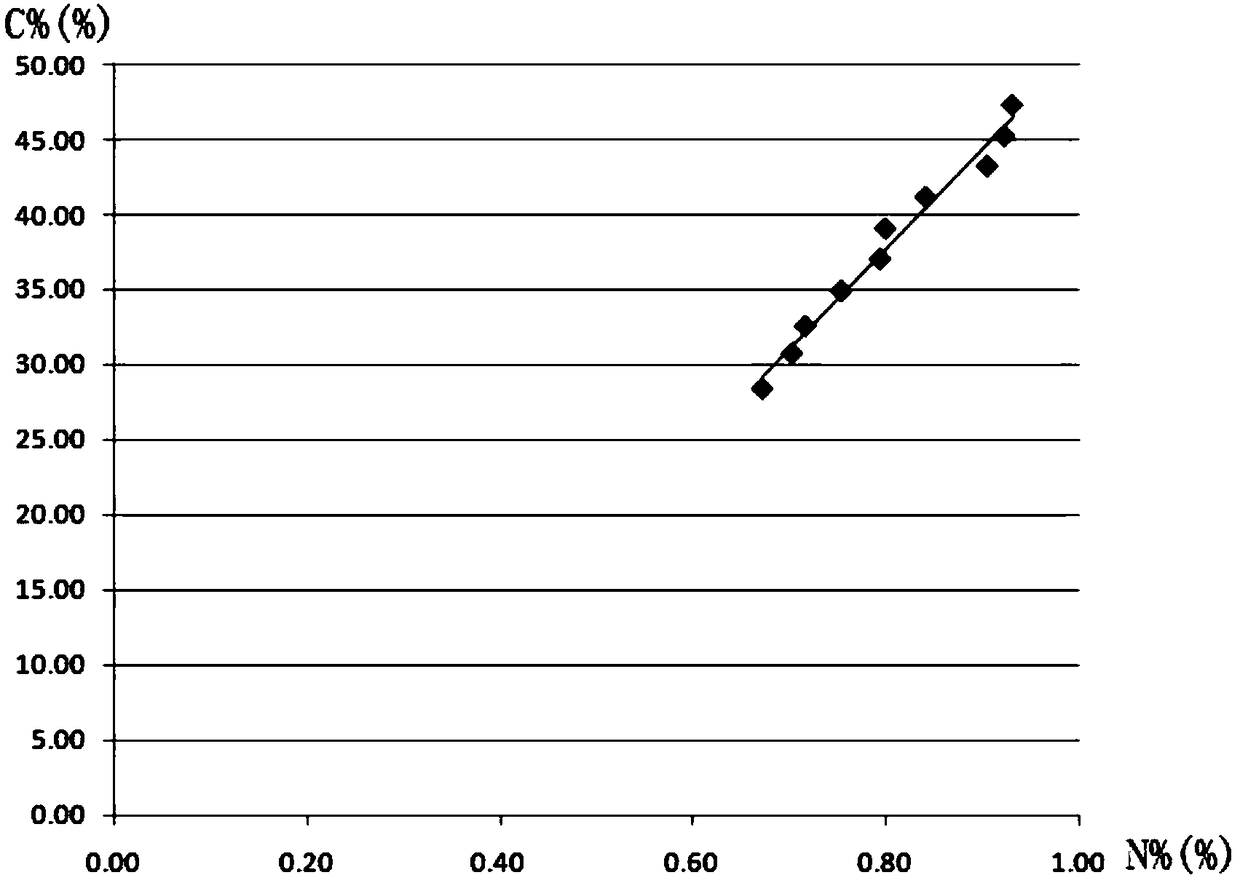

Embodiment 2

[0076] A method for determining the backfill rate of reconstituted shredded stem products, comprising the following steps:

[0077] (1) Use electronic weighing equipment to weigh the mass of No. 2 formula as m 空 of blank reconstituted stems, with a mass of m 液 The reconstituted cut stems backfill liquid, and evenly backfill it into the blank reconstituted cut stems, if necessary, the backfill liquid can be diluted with water;

[0078] The electronic weighing equipment in the step (1) is an electronic balance, which is easy to operate and accurate in weighing results;

[0079] (2) After standing still for 5 minutes, dry the reconstituted shredded stems after backfilling with drying equipment;

[0080] The drying equipment in the step (2) is an oven, which has the advantages of good drying effect and high work efficiency;

[0081] (3) After the drying is completed, the sample is placed in a constant temperature and humidity box, and after 24 hours of equilibrium, the finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com