Shell assembly and motor

A housing assembly and housing technology, which is applied to electric components, electromechanical devices, electrical components, etc., can solve problems such as unfavorable motor heat dissipation, abnormal motor operation, and sudden rise in motor temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

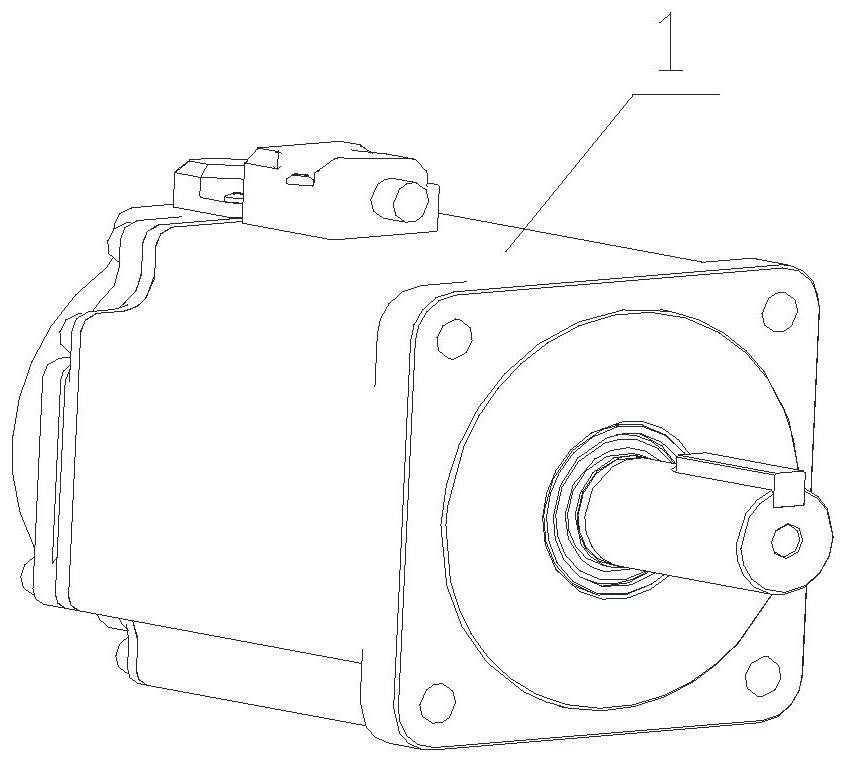

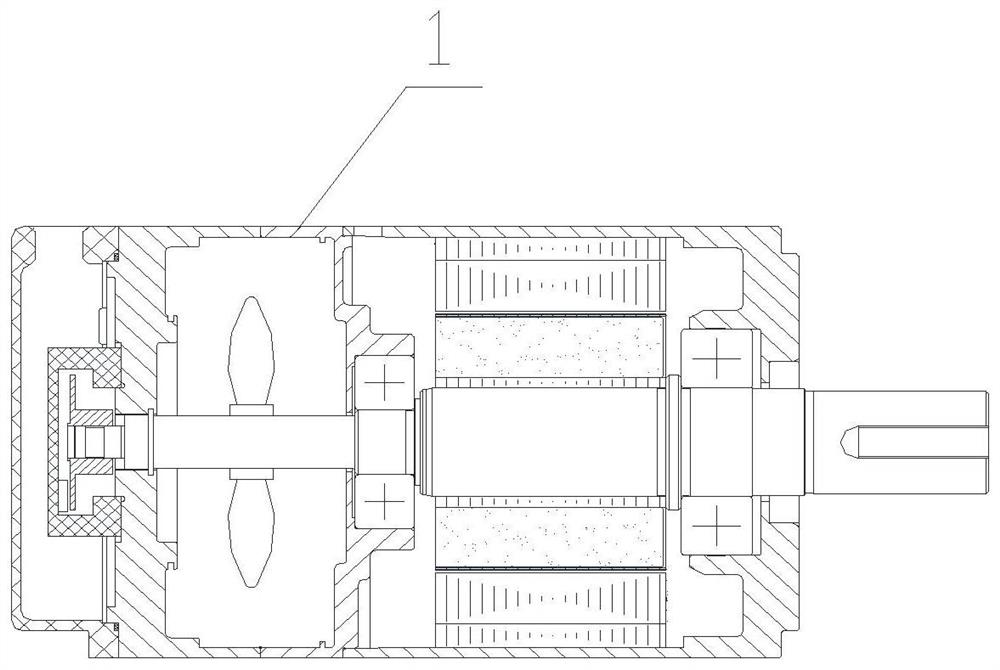

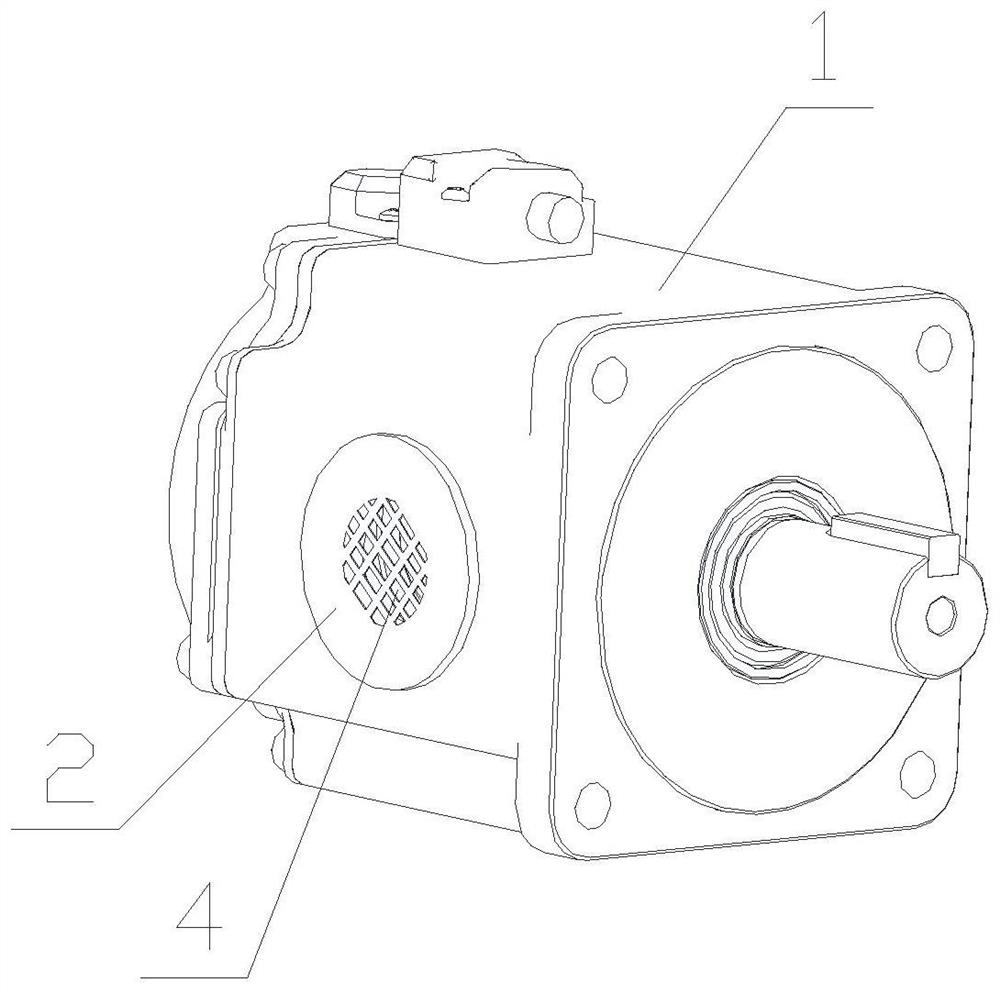

[0026] see in conjunction Figure 3 to Figure 5 As shown, according to an embodiment of the present application, a housing assembly includes:

[0027] Housing 1, the wall of the housing 1 is provided with cooling holes 11;

[0028] The air-permeable sealing component is provided with at least two layers, which are sequentially sealed and fastened on the outer side of the heat dissipation hole 11 to filter the air flowing through the heat dissipation hole 11 .

[0029] Heat dissipation holes 11 are arranged on the side wall of the housing 1, and a multi-layer ventilating sealing assembly is added outside the heat dissipation holes 11 to filter the air flowing inside and outside the housing 1; this can facilitate the circulation of air inside and outside the housing 1 and improve the The heat dissipation capability effectively solves the heat dissipation problem inside the casing 1 and prevents the impurity problem caused by the existence of the heat dissipation holes 11 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com