Environment-friendly incineration purification furnace

A purifying furnace and environmental protection technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as blocking the drying and heating of wet waste, reducing the incineration efficiency of wet waste, and achieving the effect of easy flow through.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

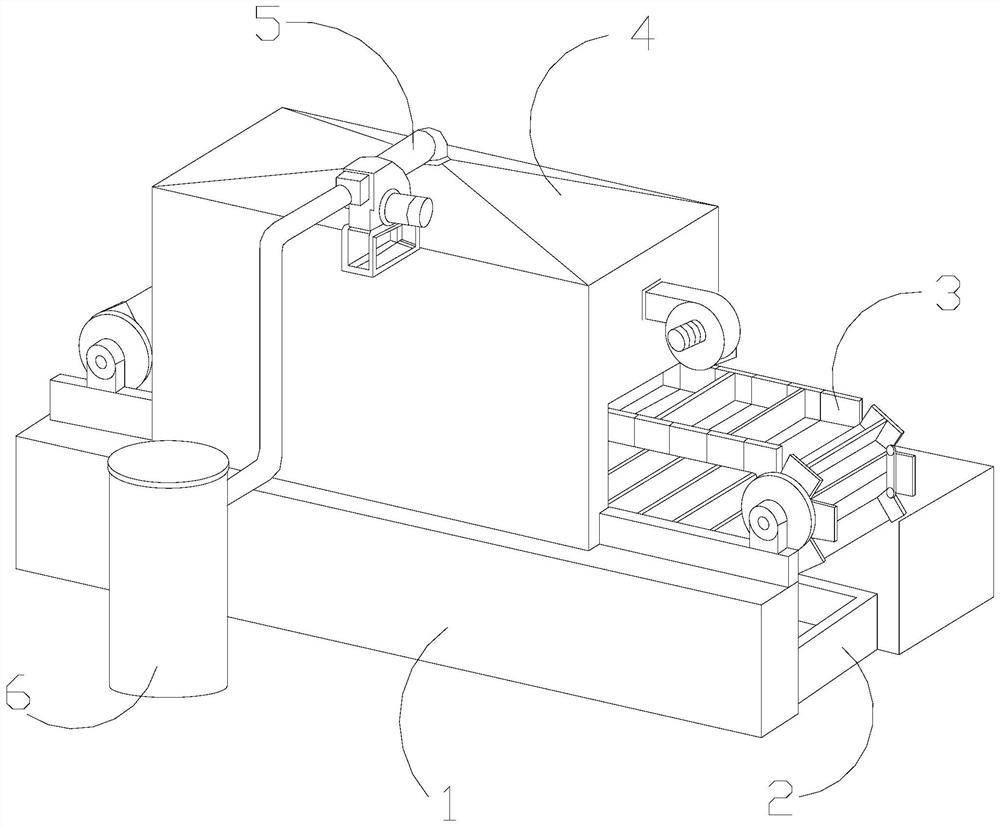

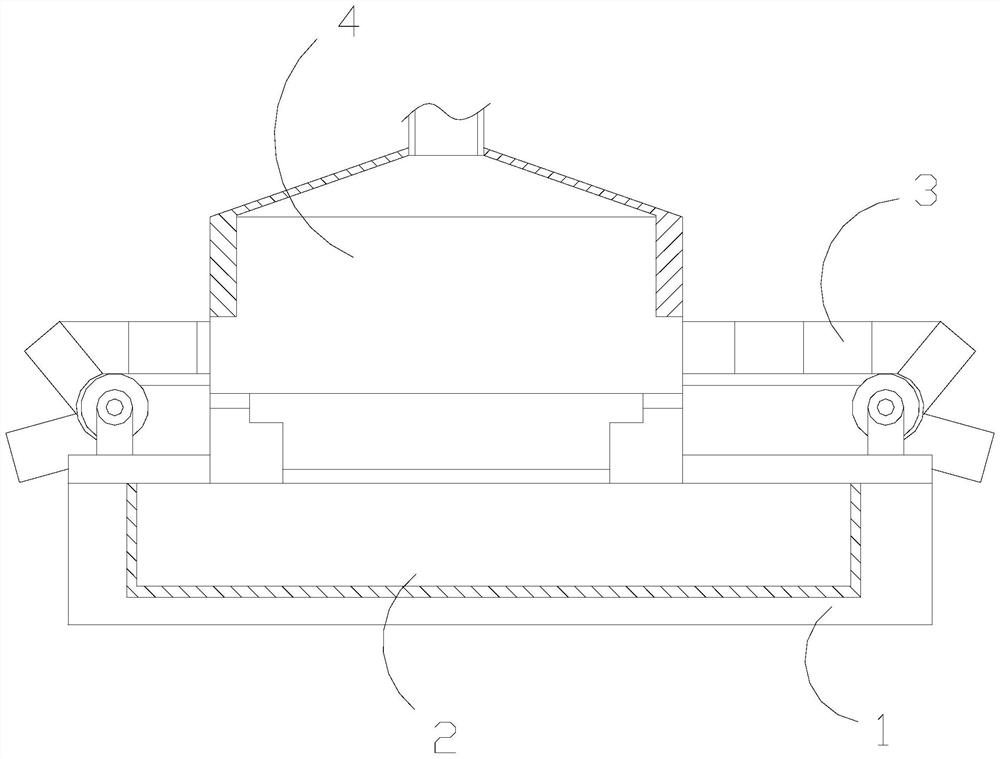

[0029] as attached figure 1 to attach Image 6 Shown:

[0030] The invention provides an environment-friendly incineration and purification furnace, which is equipped with a bottom frame 1, a bottom sump 2, a transmission frame 3, a furnace body 4, an exhaust pipe 5, and a gas collection box 6. The bottom sump 2 is located at In the middle interval position of the bottom frame 1, the transmission carrier frame 3 is located above the bottom sump 2, the furnace body 4 is fixedly installed on the bottom frame 1, and the exhaust pipe 5 is connected through the top of the furnace body 4, The gas collecting box 6 is connected to one end of the exhaust pipe 5 , and the transmission carrier frame 3 runs through and moves inside the furnace body 4 .

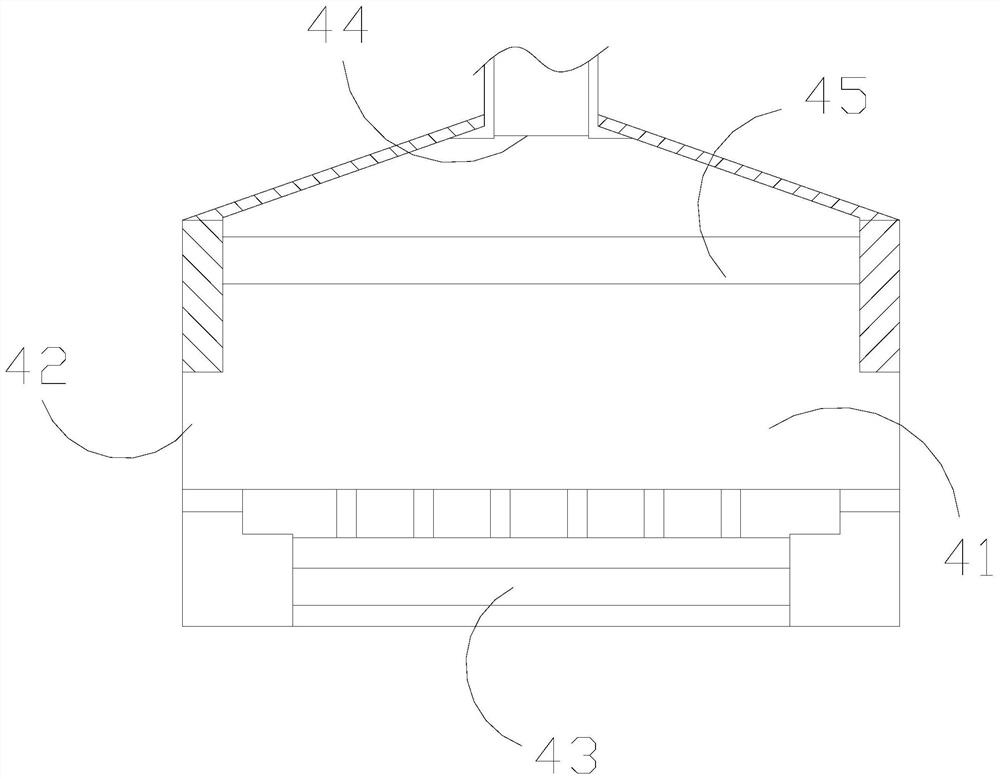

[0031] The furnace body 4 is provided with an incineration chamber 41, a side port 42, a heat-conducting bottom 43, an upper opening 44, and a transverse partition 45, and the side ports 42 are located at both sides of the incineration ...

Embodiment 2

[0037] as attached Figure 7 To attach Figure 8 Shown:

[0038] Wherein, the material collection device 241 is a card chute 411, a hinge pulley 412, a pull bar 413, a suction port 414, and a negative pressure ball 415, and the card chute 411 is located at one side of the material collection device 241, and The hinge pulley 412 is slidably connected in the card chute 411, the pull rod 413 is hingedly connected with the hinge pulley 412, the other end of the pull rod 413 is connected with the negative pressure ball 415, and the suction port 414 and the shrinkage bump 524 are Integrated structure, the negative pressure ball 415 is connected through the suction port 414, the negative pressure ball 415 is in the shape of a sphere, and the hinged pulley 412 will undergo sliding displacement under the air pressure, and at the same time, the negative pressure ball 415 will be pulled, so that The negative pressure ball 415 is under negative pressure and undergoes deformation.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com