Roll-to-roll double-sided laminating equipment and process

A laminating equipment, roll-to-roll technology, applied in electrical components, printed circuit manufacturing, printed circuit and other directions, can solve the problems of low production efficiency and high labor cost of multi-layer flex plate pressing, saving manpower, realizing automatic production, The effect of improving the efficiency of pressing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

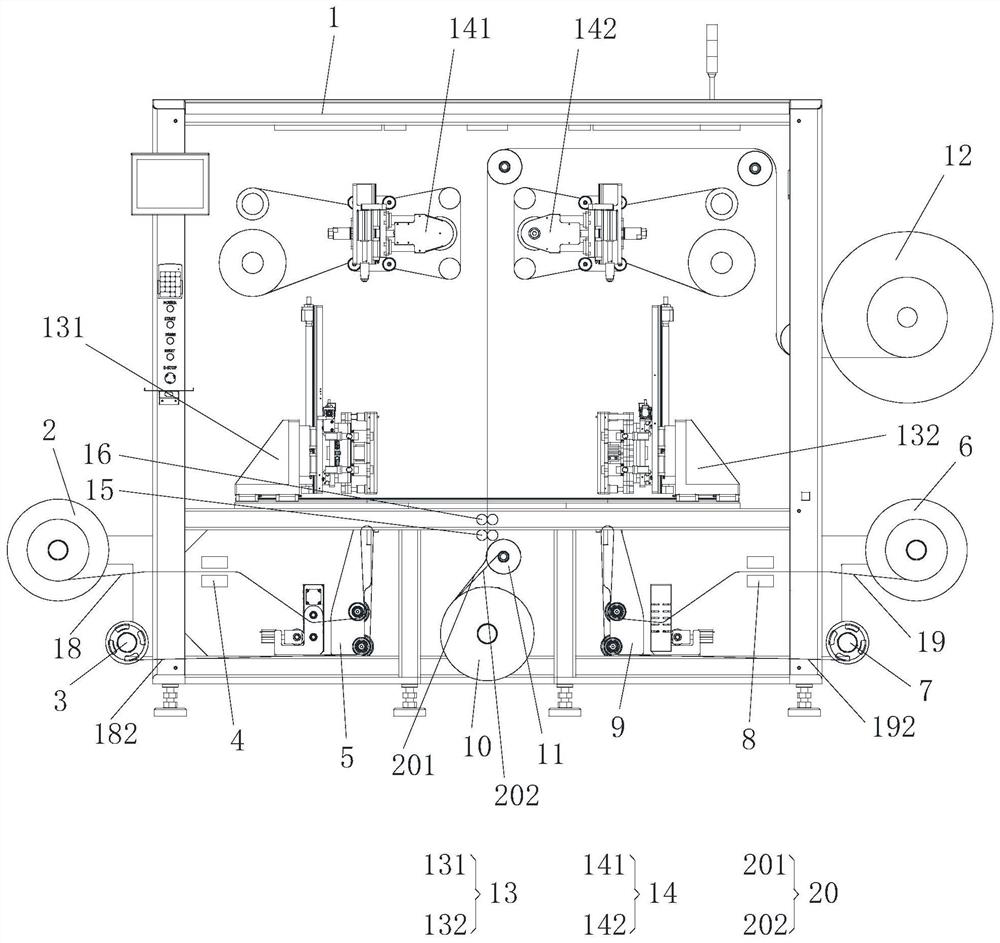

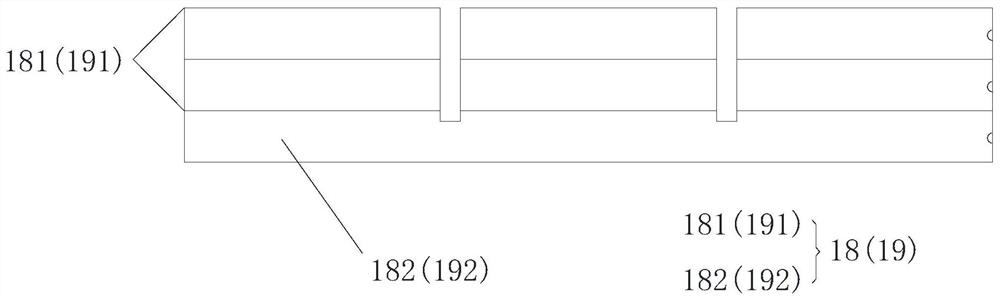

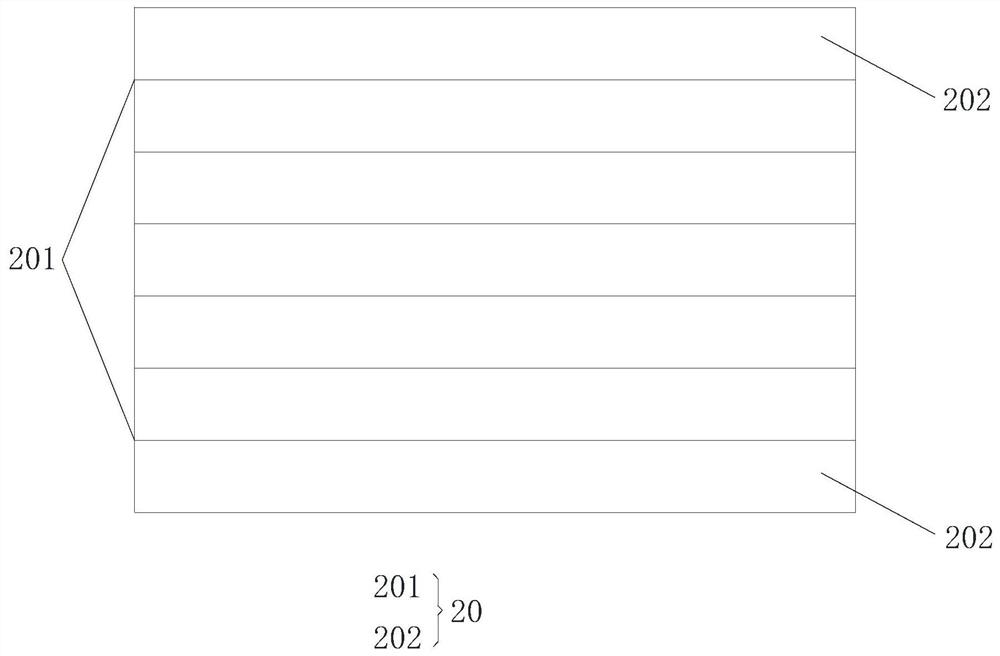

[0076] like Figure 1 to Figure 4 As shown in the figure, a roll-to-roll double-sided lamination device in this embodiment includes a body 1, and the left rubber layer threading device, the middle layer threading device and the right side are sequentially arranged on the body 1 from left to right. Adhesive layer threading device; in this embodiment, the L1 layer adhesive assembly 18 includes the L1 layer adhesive 181 and the L1 layer release film 182 arranged in layers; the L4 layer adhesive assembly 19 includes the L4 layer glue 191 and the L4 layer release film arranged in layers. The inner layer copper assembly 20 includes the L23 inner layer double-sided copper 201 and the isolation film 202 arranged in layers; wherein, the left adhesive layer threading device is suitable for transporting the L1 layer adhesive assembly 18 to the middle layer threading device, And peel off the L1 layer release film 182 and rewind, so that the L1 layer glue 181 is adsorbed on the middle laye...

Embodiment 2

[0090] like Figure 1 to Figure 8 As shown, on the basis of Embodiment 1, Embodiment 2 provides a roll-to-roll double-sided lamination process, including:

[0091] The L1 layer glue assembly 18 is unwound through the L1 layer glue unwinding mechanism 2, and then the L1 layer glue peeling and conveying mechanism 5 is transported to the left vacuum pick and place head 131, and the L1 layer glue assembly 18 is peeled off. The film 182 is transported to the L1 layer adhesive release film take-up mechanism 3 for winding, so that the L1 layer adhesive 181 of the L1 layer adhesive assembly 18 is adsorbed to the left vacuum pick-up and placement head 131 .

[0092] At the same time, the L4 layer glue assembly 19 is unwound through the L4 layer glue unwinding mechanism 6, and then the L4 layer glue stripping conveying mechanism 9 is transported to the right vacuum pick-up and placement head 132, and the L4 layer of the L4 layer glue assembly 19 is peeled off. The release film 192 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com