Device for separating metal impurities from superfine waste glass powder

A technology for metal impurities and waste glass powder, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

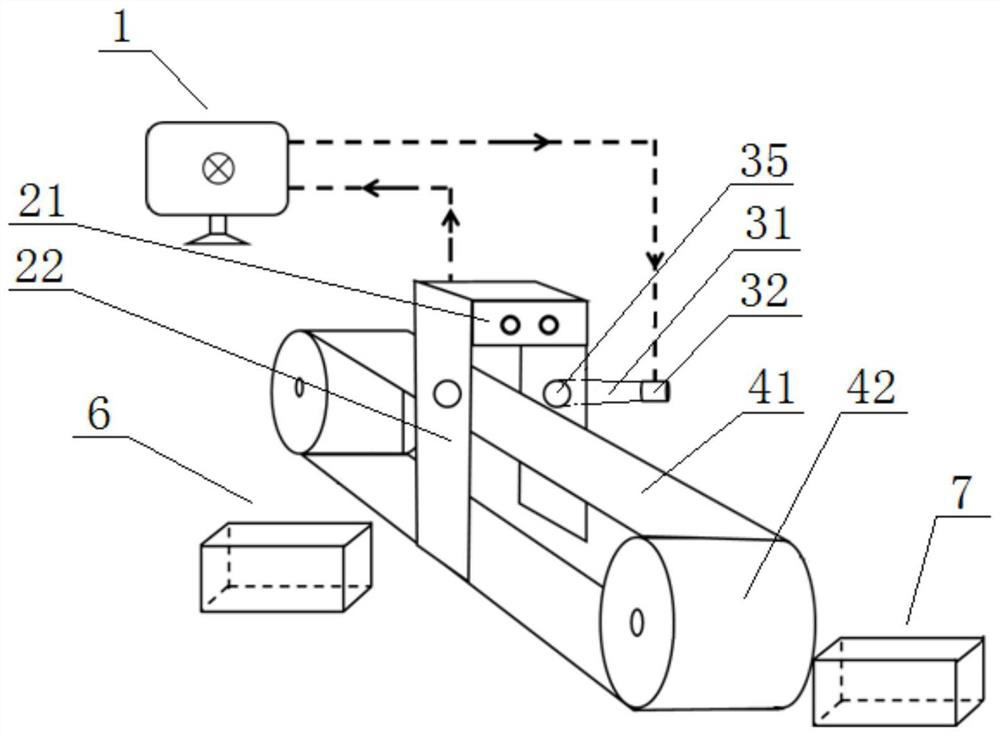

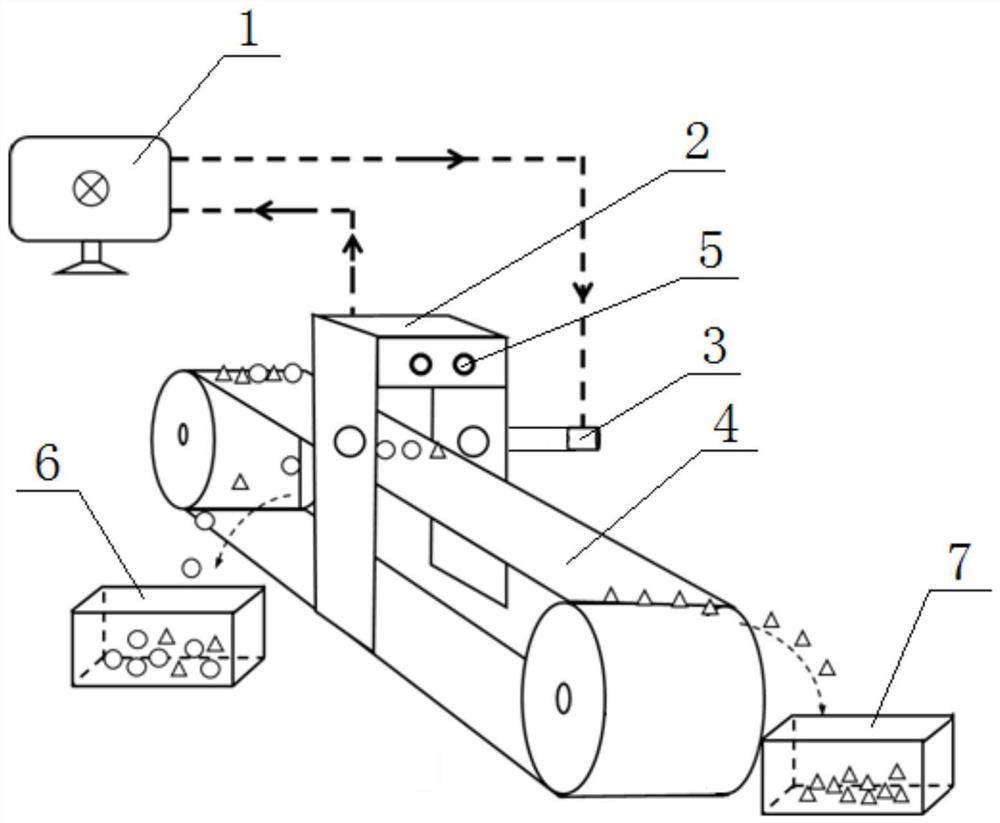

[0034] like figure 1 Shown is the first embodiment of the device for separating metal impurities in ultra-fine waste glass powder of the present invention, including a control mechanism 1 and a metal detection mechanism 2 communicating with the control mechanism 1, a spray sorting mechanism 3, and a transmission mechanism 4, The metal detection mechanism 2 is located above the conveying mechanism 4 , and the spray sorting mechanism 3 is inserted into the metal detection mechanism 2 .

[0035] The transmission mechanism 4 transports the metal-containing ultrafine waste glass powder mixture to the metal detection mechanism 2 for metal detection. When a metal signal is detected, the transmission mechanism 4 is controlled by the control mechanism 1 to stop, and then the spray sorting mechanism 3 is controlled to spray For sorting, the metal-containing mixture is blown away from the conveying mechanism 4, and then the conveying mechanism 4 is controlled to continue conveying the me...

Embodiment 2

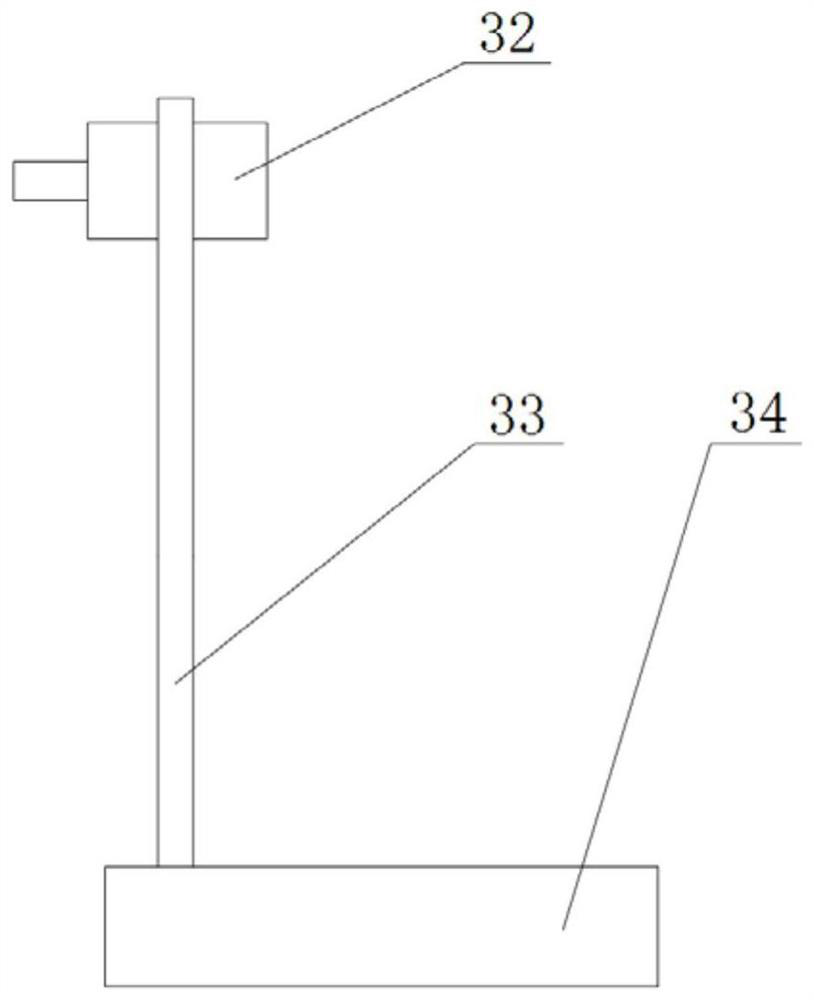

[0054] This embodiment is similar to Embodiment 1, and the difference is that in this embodiment, the spray sorting mechanism 3 also includes a movable bracket, and the movable bracket includes a bracket main body 33 and a slide mechanism 34 connected with the bracket main body 33, and the injector 32 is connected with the bracket main body 33. The bracket main body 33 is connected, and the sliding mechanism 34 is electrically connected with the control mechanism 1 . The setting of the sliding mechanism 34 enables the distance between the injector 32 and the metal detection mechanism 2 to be adjusted, which is convenient for operators to operate. like figure 2 As shown, the sliding mechanism 34 is a screw mechanism, the motor of the screw mechanism is electrically connected to the control mechanism 1 , the nut of the screw mechanism is connected to one end of the bracket body 33 , and the injector 32 is connected to the other end of the bracket body 33 . It should be noted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com