Separation device of axial diode

An axial diode and separation device technology, applied in sorting and other directions, can solve the problems of unfavorable promotion and application, a lot of time, energy, complicated design structure, etc., and achieve the effect of exquisite structure, improving separation efficiency and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

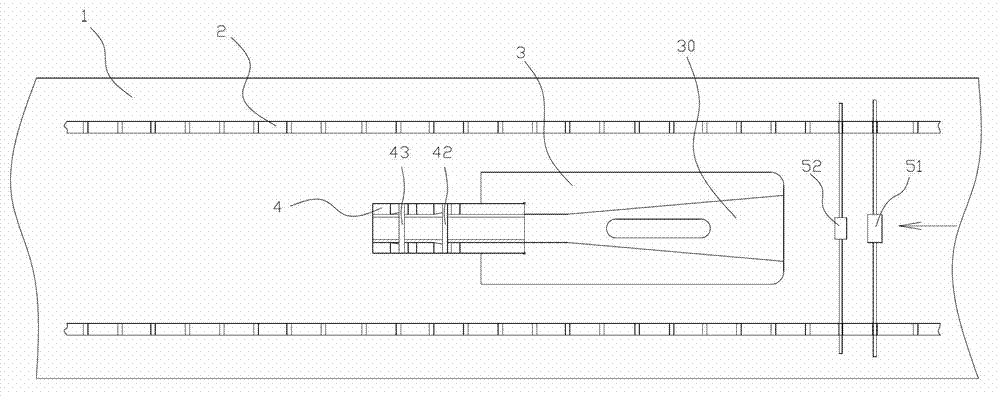

[0023] The present invention as Figure 1-7 As shown, the axial diode includes a diode body and a pair of lead wires arranged at both ends of the diode body, the axial diode is connected to two parallel conveyor chains 2 through the pair of lead wires, and the conveyor chain 2 is set on the workbench 1;

[0024] The separation device is arranged on the workbench 1 and is located between the two conveying chains 2; the separation device includes a limit fixing seat 3 and a separation seat 4 connected together, and the limit fixing seat 3 is located at the front end of the separation seat 4;

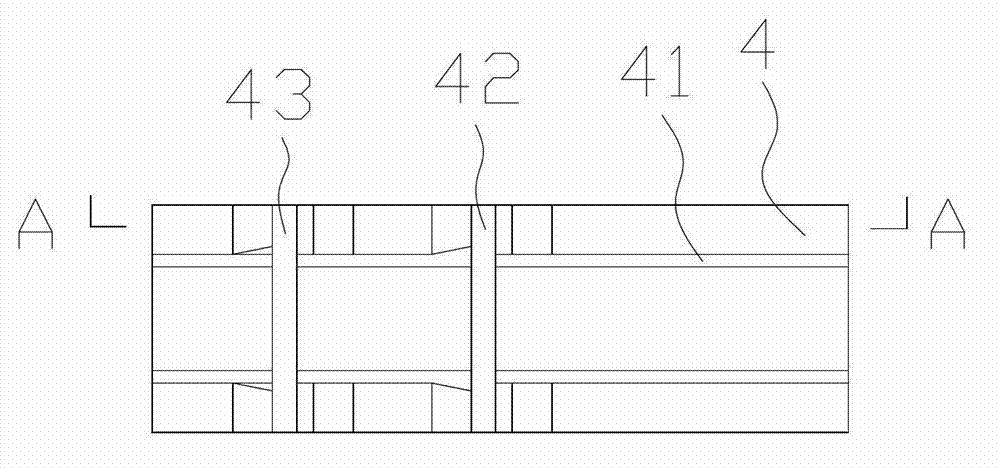

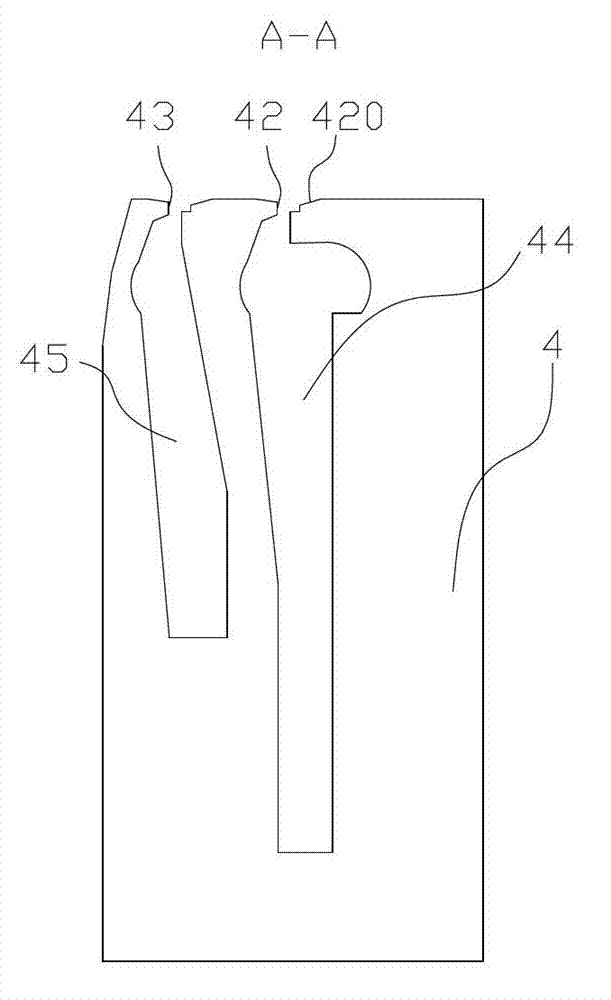

[0025] The center of the top surface of the limit fixing seat 3 is provided with a guide groove 30 parallel to the conveying chain 2, and the center of the top surface of the separation seat 4 is provided with a step that is large up and down small and communicated with the guide groove 30. Groove 41, the groove width of the large groove of the step groove of the separation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com