Tubular structure aviation chair back composite material product mold adopting mold pressing process

A technology of tubular structure and composite material, applied in the field of product molds, can solve the problems of easy tilting of inserts, difficult removal of preformed mandrels, product clamping, etc., achieves uniform wall thickness, solves difficulty in taking parts, and has good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

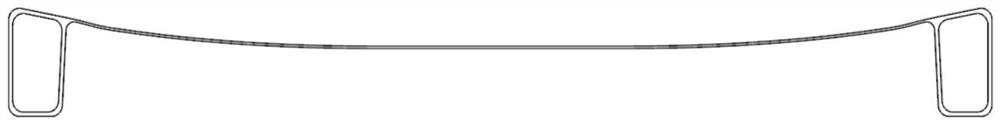

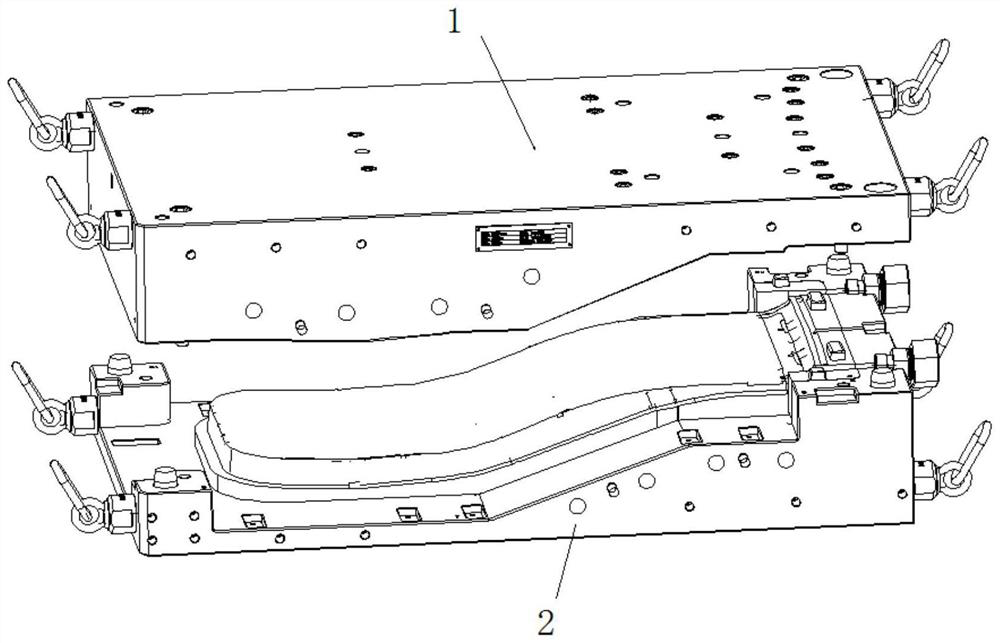

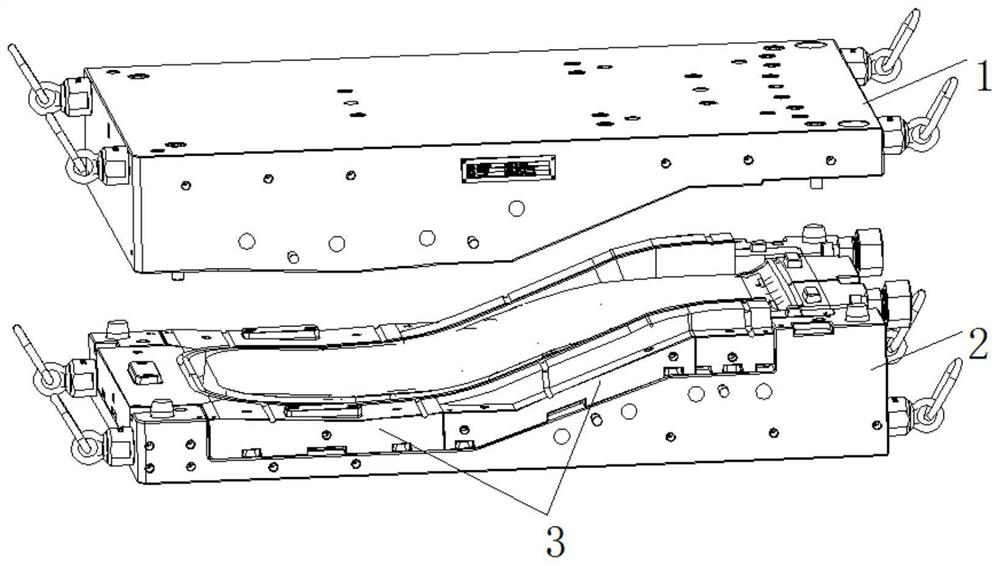

[0028] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. figure 1 Schematic diagram of the structure of the product made for practical use of the present invention. figure 2 It is a schematic diagram of the overall structure of the mold provided by the present invention. image 3 It is a structural schematic diagram of the installation position of the side-drawing slider structure. Figure 4 It is an auxiliary blowing structure in the present invention. As shown in the above figure: the tubular structure aviation seat back composite product mold of the molding process provided by the present invention includes: an upper mold cavity 1, a lower mold cavity 2, a side-drawing slider 3, an auxiliary blowing structure 4; a side-drawing slide The block 3 is located between the upper mold cavity 1 and the lower mold cavity 2, and the auxiliary blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com