Advanced speed change method and device based on injection molding machine manipulator

A speed change device and manipulator technology, applied in the field of advance speed change method and device based on injection molding machine manipulator, can solve the problems of poor structural strength, product loss, broken, etc., and achieve the effect of flexible speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

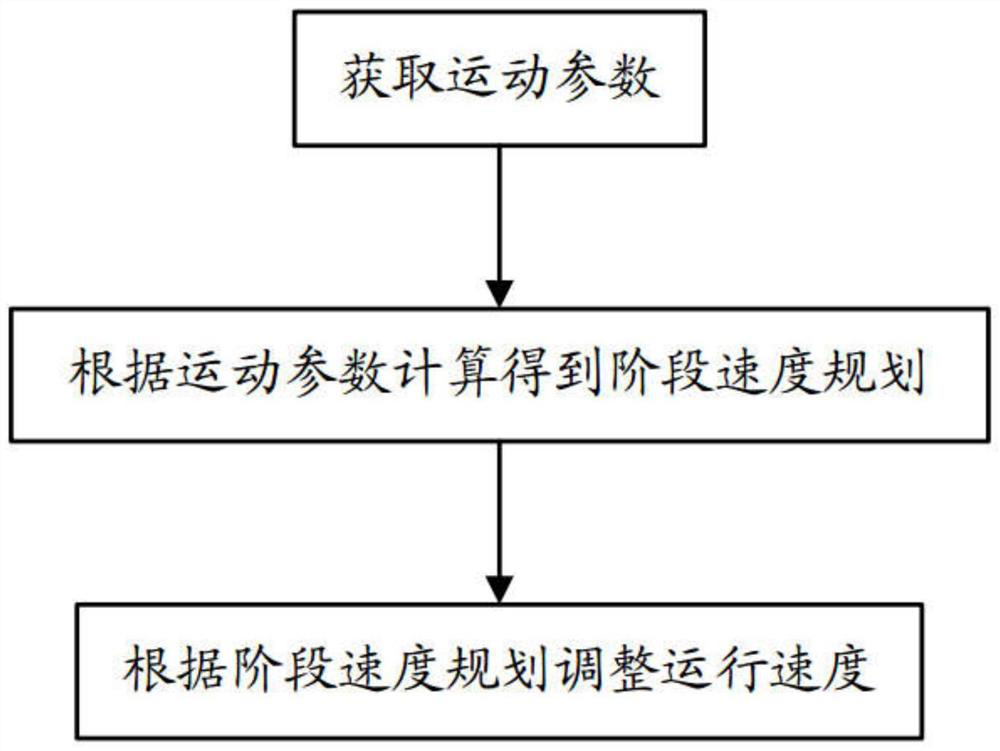

[0034] see figure 1 , an advance shifting method based on an injection molding machine manipulator, including:

[0035] Obtain motion parameters, which include motion distance S, maximum acceleration A, advance shift distance Sd, first stage speed Vobj1, second stage speed Vobj2 and interpolation period Ts;

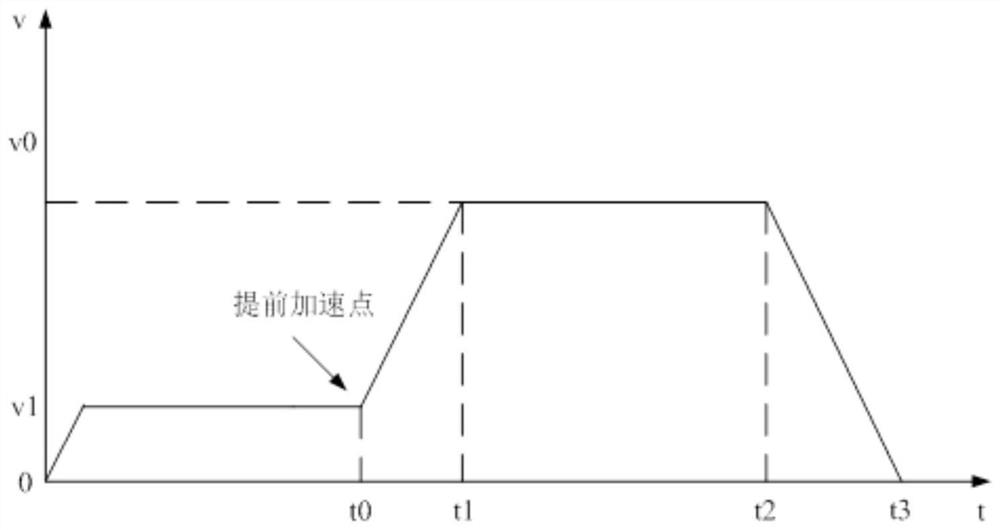

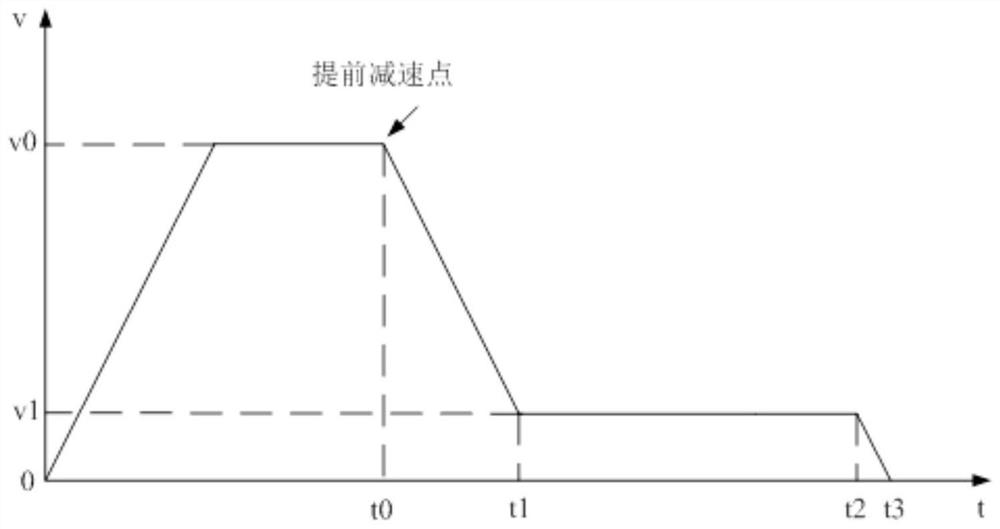

[0036] According to the calculation of the motion parameters, the phase speed planning is obtained, and the phase speed planning includes a first speed planning phase and a second speed planning phase,

[0037] The first speed planning stage includes a first variable speed stage and a first constant speed stage;

[0038] The second speed planning stage includes a second speed change stage, a second constant speed stage and a third speed change stage;

[0039] Calculate the movement distance according to the running speed, judge whether the movement distance reaches the speed change point, and adjust the running speed according to the stage speed planning.

[0040] The ...

Embodiment 2

[0085] The present invention also relates to an advance shifting device based on an injection molding machine manipulator, including an acquisition module, a calculation module, an execution module and a judgment module,

[0086] The acquisition module is used to acquire motion parameters, the motion parameters include motion distance S, maximum acceleration A, advance shift distance Sd, first stage speed Vobj1, second stage speed Vobj2 and interpolation period Ts;

[0087] The calculation module is used to calculate and obtain a stage speed plan according to motion parameters, and the stage speed plan includes a first speed plan stage and a second speed plan stage,

[0088] The first speed planning stage includes a first variable speed stage and a first constant speed stage;

[0089] The second speed planning stage includes a second speed change stage, a second constant speed stage and a third speed change stage;

[0090] The calculation module is also used to calculate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com