Bogie axle box gap correction method and device

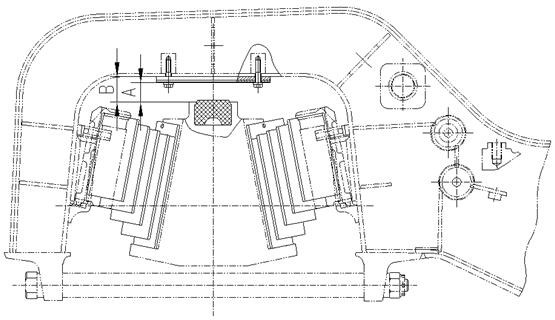

A bogie shaft and bogie technology, applied in the field of bogie axle box clearance correction, can solve problems such as affecting passenger comfort, reducing vibration and noise reduction effects, etc., to increase working height, eliminate working height settlement, and improve comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

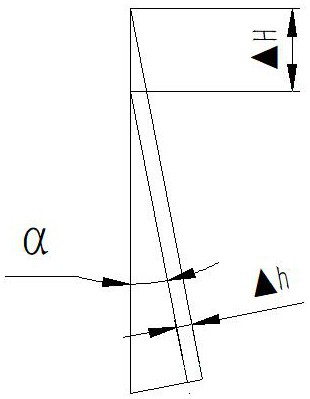

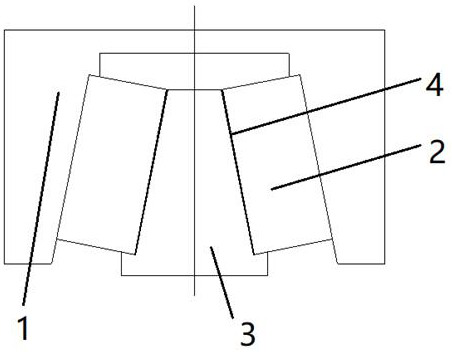

[0026]Embodiment 1: A rigid spacer (4) with a thickness of Δh is added between the contact surface of the bogie axle box (3) and the chevron spring (2).

[0027]Such asimage 3 As shown, a rigid spacer (4) with a thickness of Δh can be added between the contact surface of the bogie axle box (3) and the chevron spring (2). Through the above theoretical expression, the frame (1) and The gap between the top surfaces of the herringbone spring (2) produces an increase of ΔH. In this embodiment, the rigid spacer (4) is preferably a rigid gasket, which is laid between the contact surface of the bogie axle box (3) and the chevron spring (2) and covers the chevron spring (2) and The entire contact surface of the bogie axle box (3) makes the gasket in a V shape, so that the contact surface of the gasket and the herringbone spring (2) fits better. In this embodiment, the V-shaped gasket includes a pair, which are respectively arranged between the contact surfaces of the chevron spring (2) and the ...

Embodiment 2

[0029]The second embodiment: the second rigid spacer (5) with a thickness of ΔH is added between the contact surface of the frame (1) and the chevron spring (2).

[0030]According to the theoretical relationship between the thickness increase Δh of the herringbone spring (2) and the gap increase ΔH between the frame (1) and the top surface of the herringbone spring (2), it is also possible to directly compare the frame (1) and the herringbone spring (2) Correct the gap between them. Specific asFigure 4 As shown, a second rigid spacer (5) with a thickness of ΔH is added between the contact surface of the frame (1) and the chevron spring (2). The material of the second rigid spacer (5) can be the same as that of the first embodiment. In addition, the second rigid spacer (5) covers the entire contact surface of the herringbone spring (2) and the frame (1), so that the second rigid spacer (5) is in a V shape. Rigid spacer one (4), in addition to the integrated V-shaped gasket, can also be ...

Embodiment 3

[0032]Embodiment 3: Add a rigid spacer (4) with a thickness of Δh between the contact surface of the bogie axle box (3) and the chevron spring (2), and the frame (1) and the chevron spring (2) Two rigid spacers (5) with a thickness of ΔH are added between the contact surfaces.

[0033]The third embodiment combines the setting methods of the first and second embodiments. This embodiment can ensure the expected clearance correction amount ΔH while minimizing the impact on the overall rigidity of the entire axle box frame. In the specific implementation, a V-shaped gasket with a thickness of Δh can be laid between the contact surface of the bogie axle box (3) and the chevron spring (2); a flat gasket with a thickness of ΔH is laid on the frame (1) Between the contact surface with the herringbone spring (2). The V-shaped gasket is combined with the flat gasket to form an L-shaped gasket, which ensures that the contact surface of the herringbone spring (2) and the gasket will not move relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com