Construction engineering repair working frame

A technology for maintenance work and construction engineering, applied in construction, building structure, accessories of scaffolding, etc., can solve problems such as affecting work, danger, inconvenience, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

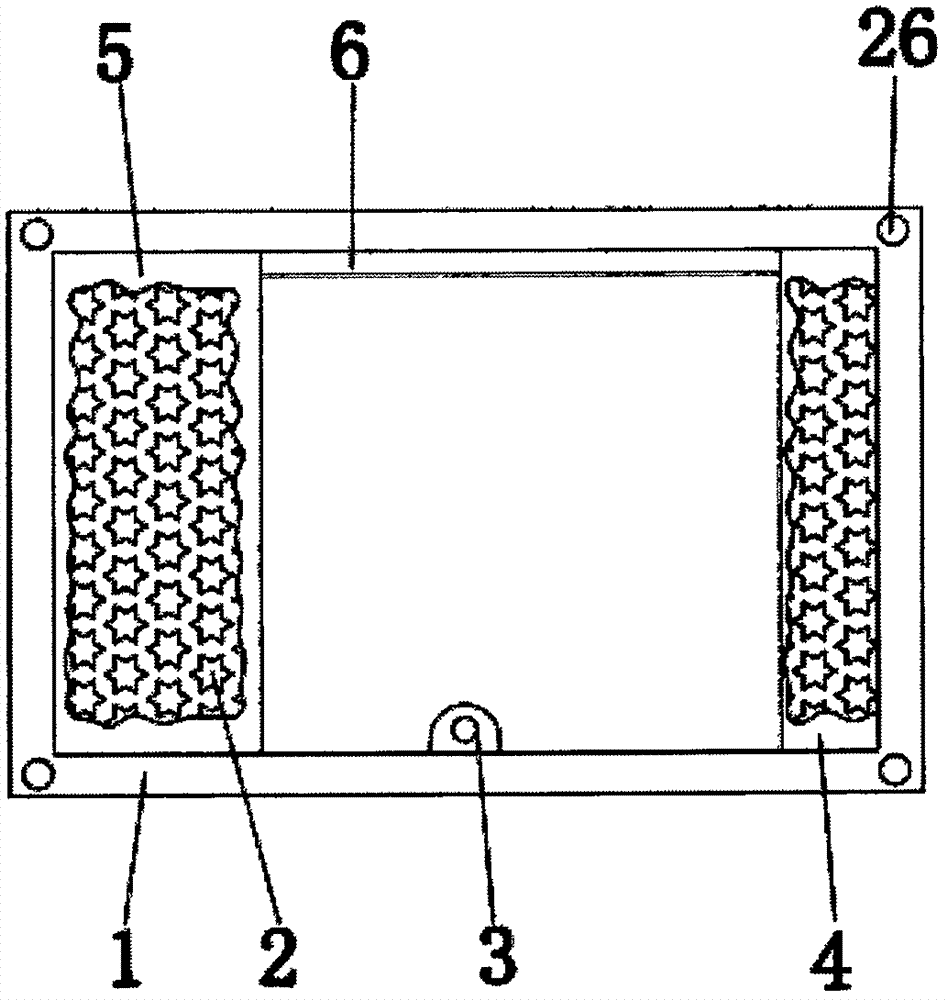

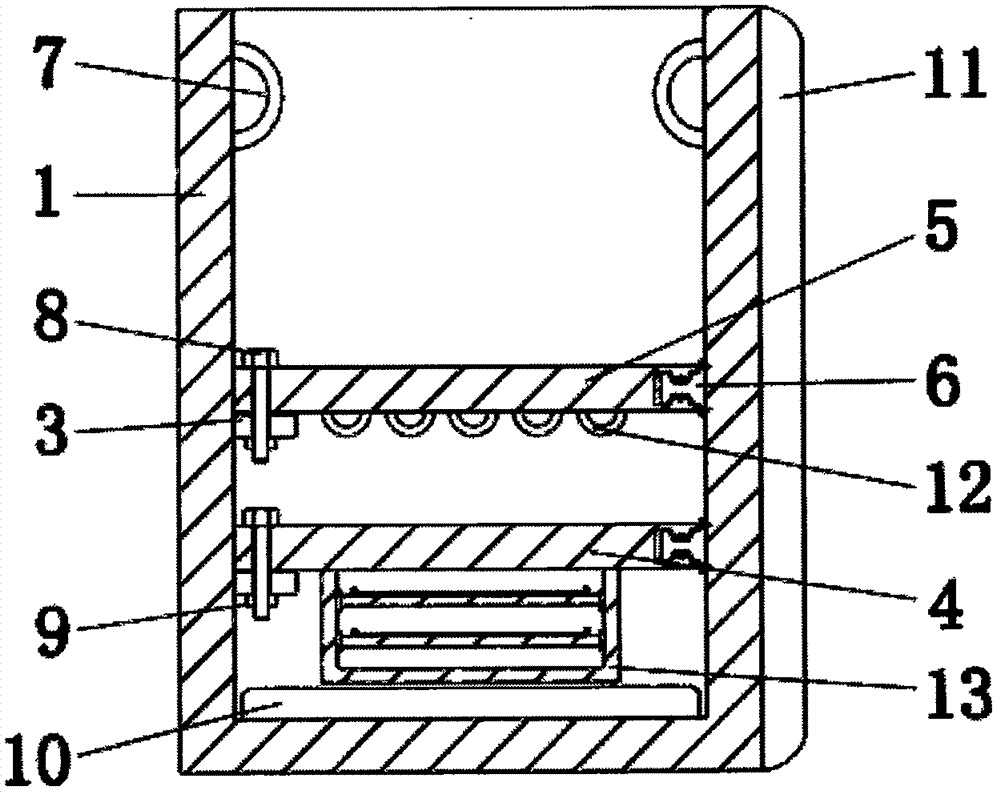

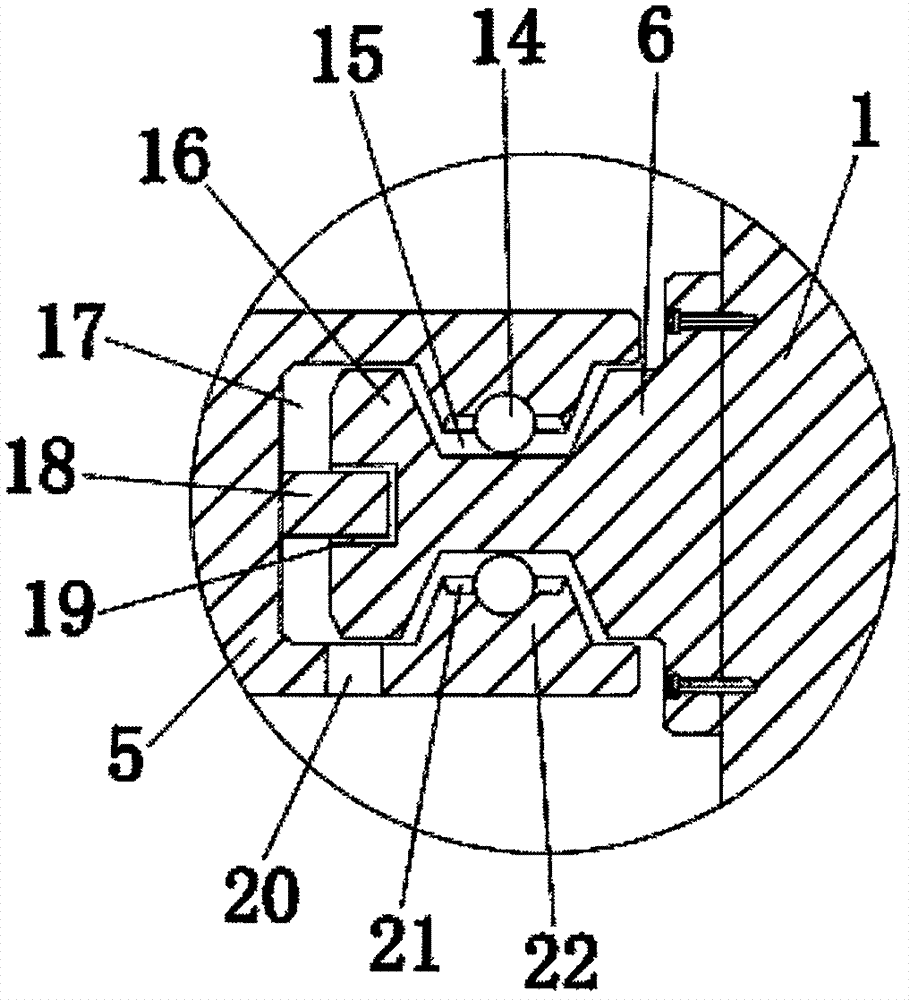

[0021] Example 1: Please refer to Figure 1-6 , the present invention provides a technical solution: a construction maintenance work stand, including a frame body 1, a foam backing plate 11 is pasted on the right side of the outer wall of the frame body 1, and handles are installed on the left and right sides of the inner top of the frame body 1 7. The four corners of the front of the frame body 1 are provided with a central tube 26, and the outer top of the central tube 26 is sleeved with a pressure seat 25, and the pressure seat 25 is connected with the frame body 1 and the central tube 26 through fixing bolts 24, and the center tube 26 The bottom rod 29 is connected through the inside, and the top of the bottom rod 29 is equipped with a suspension ring 28. A tightening tube 30 is installed at the top of the connection between the central tube 26 and the bottom rod 29, and a gland 27 is installed on the top of the tightening tube 30 to tighten The cylinder 30 is a rubber cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com