Obstacle-avoiding carrying trolley for logistics storage

A technology for handling trolleys and obstacle avoidance, which is applied in the field of obstacle-avoidable handling trolleys for logistics and warehousing. It can solve problems such as trolley dumping, damaged items, and obstacles that are difficult to see, so as to achieve the effect of easy storage and improved transportation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

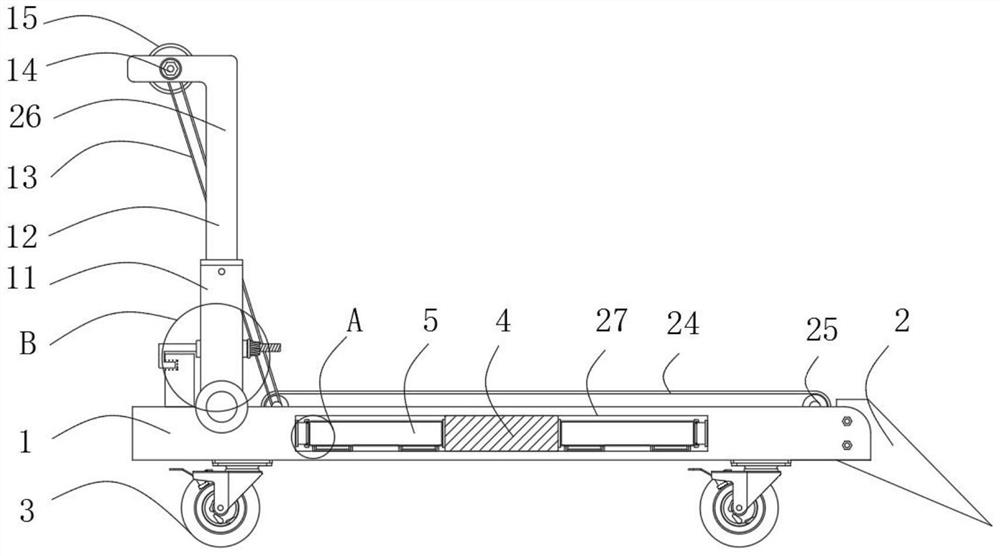

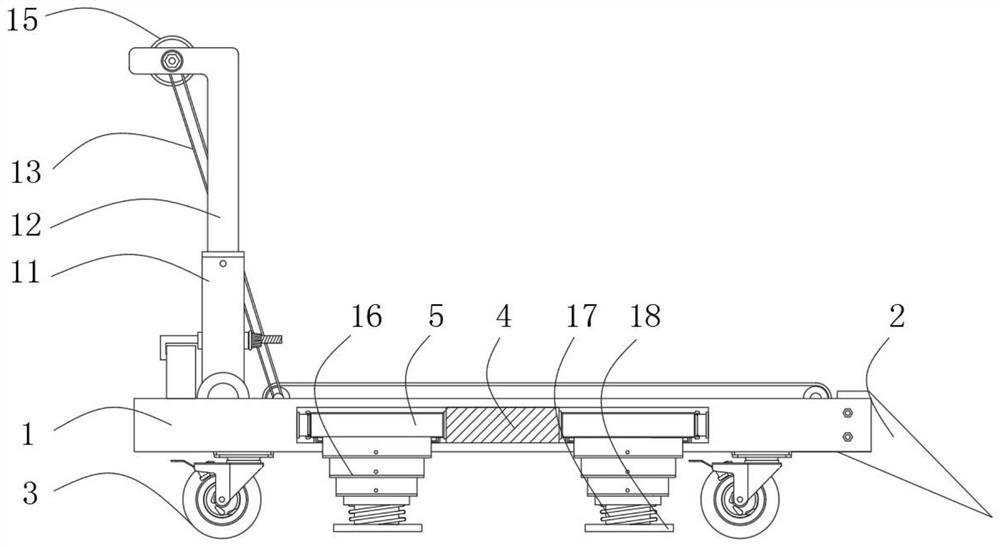

[0024] Example 1, such as Figure 1-4 As shown, the present invention provides an obstacle-avoidable handling trolley for logistics storage, including a base plate 1, shock absorbing mechanisms 27 are arranged on both sides of the base plate 1, a rotating shaft 23 is installed on the top of the base plate 1, and the top of the base plate 1 passes through the rotating shaft 23 A handrail mechanism 26 is fixed, and a discharge mechanism 25 is installed on the top of the bottom plate 1 .

[0025] Let's talk about the specific settings and effects of the shock absorber mechanism 27, the armrest mechanism 26 and the discharge mechanism 25 below.

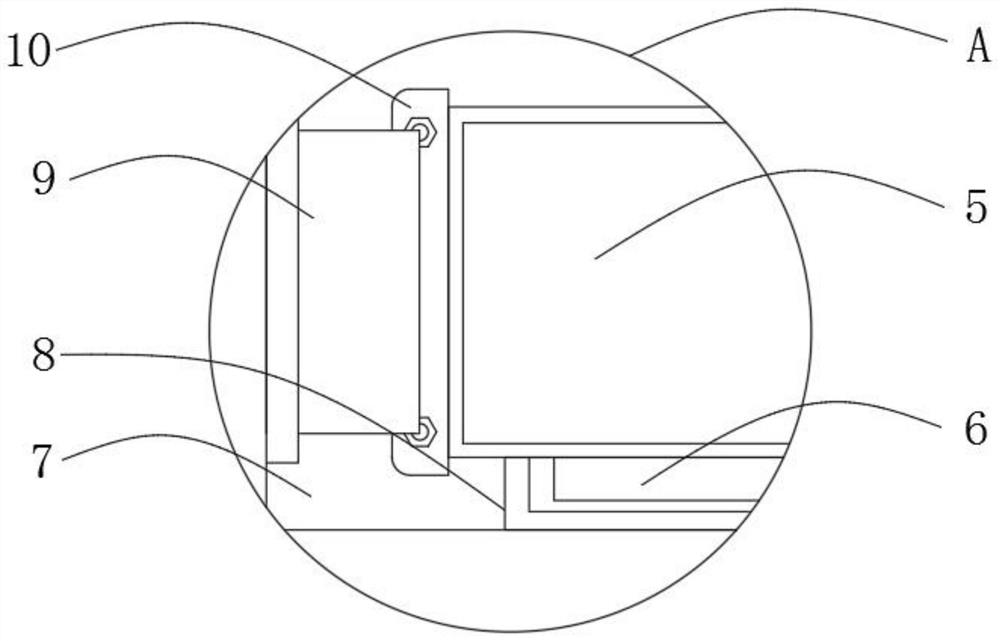

[0026] Such as Figure 1-3 As shown, the inside of the shock-absorbing mechanism 27 includes fixed grooves 7 provided on both sides of the base plate 1, the inner bottom surface of the fixed groove 7 is welded with a sliding groove 8, and the inner surfaces of both sides of the fixed groove 7 are welded with a limiting plate 9, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com