Fastening screw not prone to loosening

A technology that is not easy to fasten screws and is applied in the direction of threaded fasteners, locking fasteners, screws, etc., which can solve the problems of consuming manpower, material and financial resources, labor and time for inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

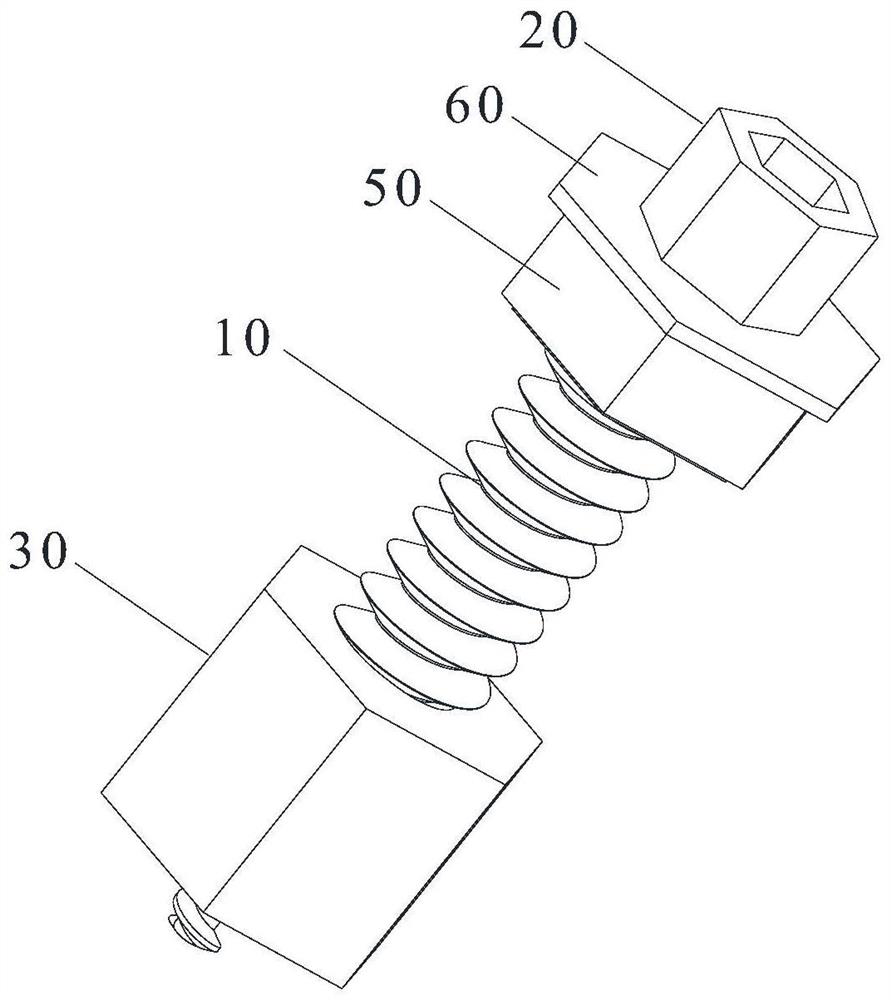

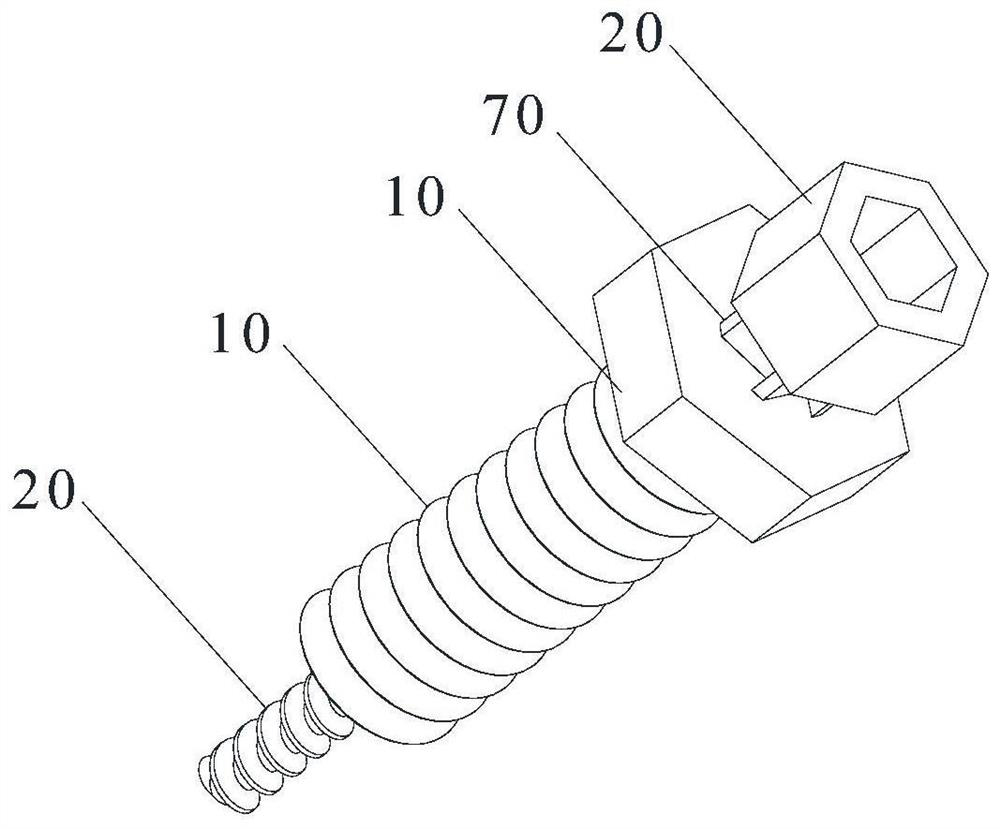

[0074] Such as Figure 1-11 As shown, the present invention provides a fastening screw that is not easy to loosen, including: a large screw 10 coaxially arranged, a small screw 20, a workpiece 30, a sleeve cap 50, a drive plate 60 and a rotating member 70; wherein, the The large screw 10 and the small screw 20 are installed in the same direction, and the rotating member 70 adopts a top groove 71 with an acute opening angle;

[0075] Specifically:

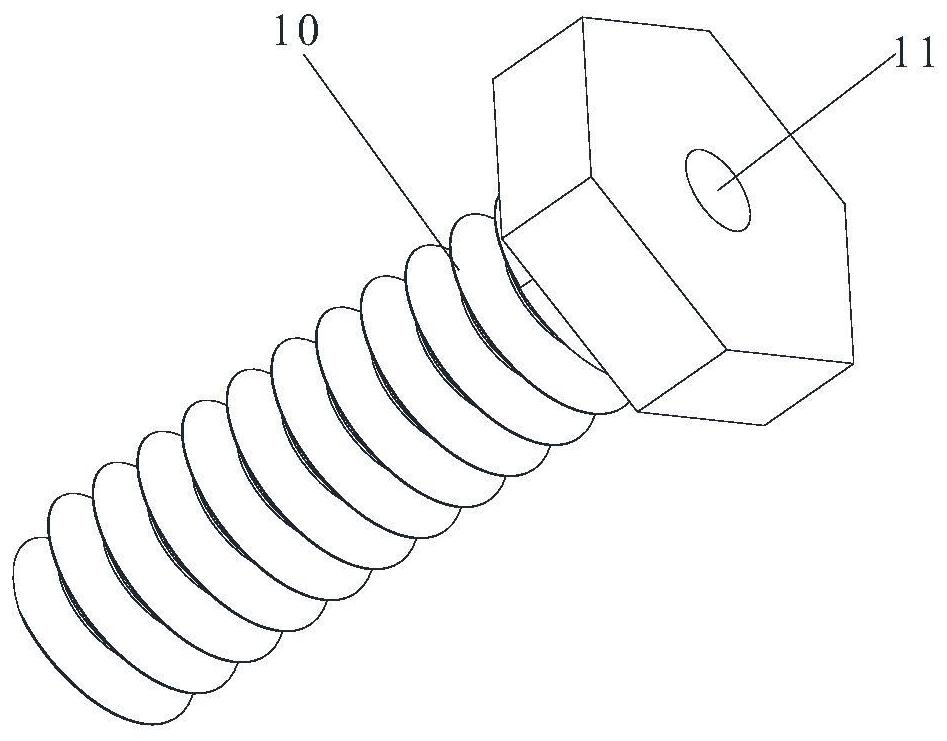

[0076] Such as image 3 As shown, the large screw 10 of the present invention is provided with a through hole 11 for the small screw 20 to pass through. The through hole 11 can be a threaded hole or a common smooth through hole. On the contrary or the same direction of rotation and different tooth pitches; the workpiece 30 of the present invention is provided with a large internally threaded hole 31 and a small internally threaded hole 32 in a stage shape, and the screw threads of the large internally threaded hole 31 and the smal...

Embodiment 2

[0088] Such as Figure 12 , 13 As shown, the present invention provides a fastening screw that is not easy to loosen. The difference between it and Embodiment 1 is that the opening angle of the top groove 71 is a right angle or an obtuse angle that can prevent the thimble from slipping.

[0089] The present invention provides a method for installing fastening screws, which is consistent with Embodiment 1;

[0090] The present invention provides a method for dismounting fastening screws. Since the opening angle of the top groove 71 is a right angle or an obtuse angle that can prevent the thimble from slipping, the thimble 51 has a space to open, so the driving plate 60 can be directly rotated to make the thimble 51 detach from the top. Groove 71; the subsequent disassembly method is consistent with that of Embodiment 1.

Embodiment 3

[0092] Such as Figures 14 to 16As shown, the present invention provides a fastening screw that is not easy to loosen, including: a coaxially arranged large screw 10, a small screw 20, a nut 40, a sleeve cap 50, a drive plate 60 and a rotating member 70; wherein, the embodiment 3 The large screw 10 and the small screw 20 are installed oppositely, and the rotating member 70 adopts a top groove 71 with an acute opening angle;

[0093] The difference with Embodiment 1 is that the present embodiment is provided with a small internally threaded hole 32 cooperating with the small screw 20 on the large screw 10, and the small internally threaded hole 32 can be a through hole or a blind hole; Matching large internal threaded hole 31, the nut 40 is provided with a washer 41 with a small center hole, the washer 41 and the nut 40 can be a separate structure or an integrated structure, the washer 41 provides a mounting platform for the rotating part 70, and the small The screw 20 can pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com