Full-automatic plug seedling transplanter

A technology for plug seedlings and transplanting machines, which is applied in the field of transplanting machines, and can solve problems such as speed difference, ejection of plug seedlings, and transplanting loss of plug seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

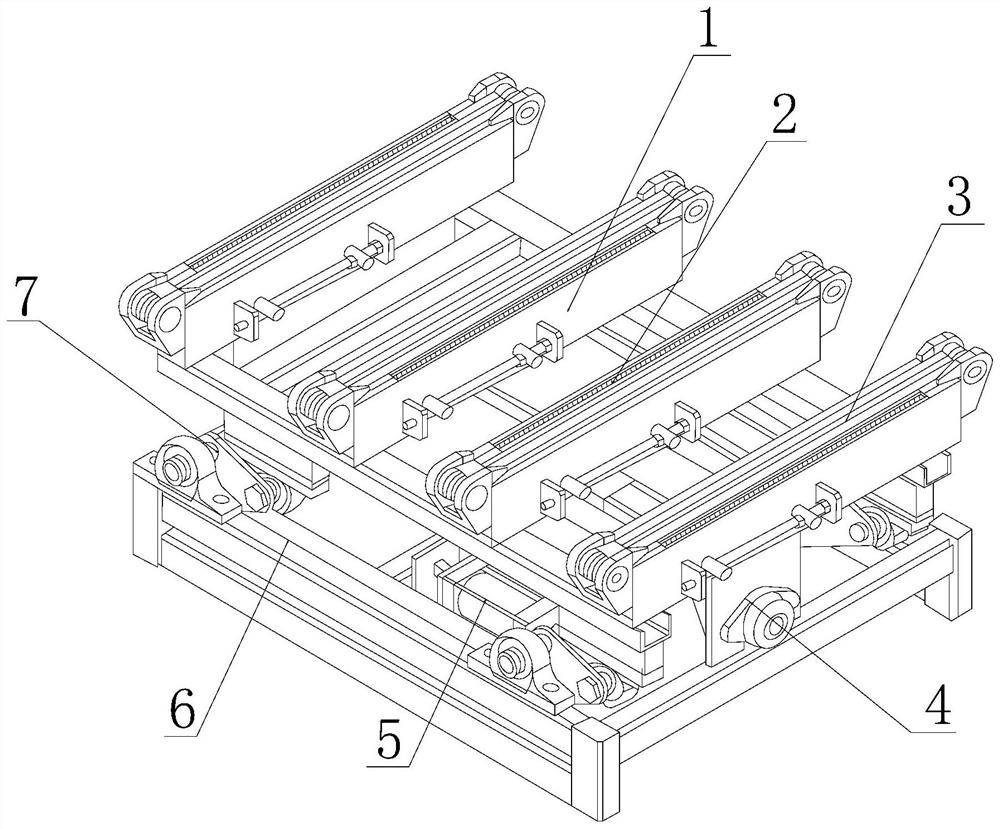

[0026] as attached figure 1 to attach image 3 Shown:

[0027] Its structure includes a bearing platform 1, an anti-fall guard plate 2, a guide bar 3, a driver 4, a jacking machine 5, a support frame 6, and a fixing hoop 7, and the bearing platform 1 is embedded and connected with both sides of the anti-fall guard plate 2 , the anti-drop guard plate 2 is in clearance fit with the outer side of the guide strip 3, the actuator 4 is movably matched with the bottom of the bearing platform 1, the jacking machine 5 is fixed with the inner bolts of the support frame 6, and the fixing hoop 7 is connected with the support The frame 6 is connected with a brand name bolt, and the inside of the transmission 4 is embedded and connected with the fixing hoop 7 .

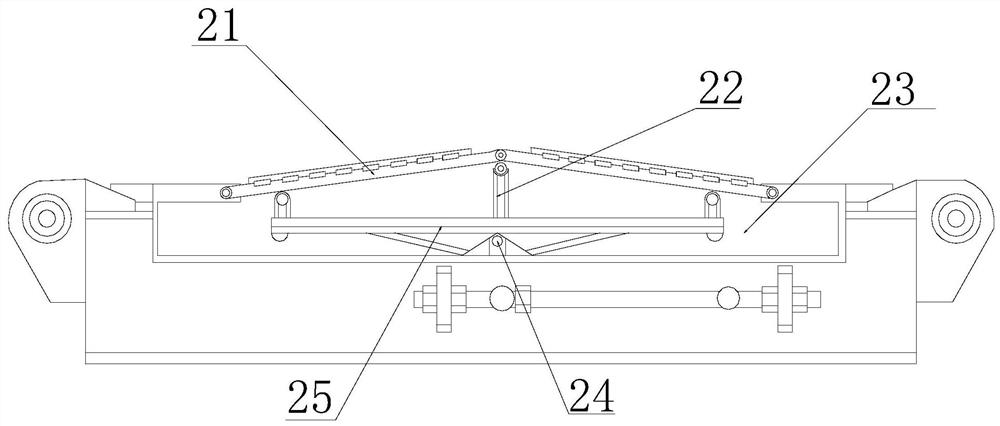

[0028] Wherein, the anti-drop protection plate 2 includes a guide plate 21, a slide bar 22, a movable chamber 23, a gimbal 24, and a slide rail 25. The bottom end is slidably matched, the balance frame 24 is welded to the inner ...

Embodiment 2

[0033] as attached Figure 4 to attach Figure 7 Shown:

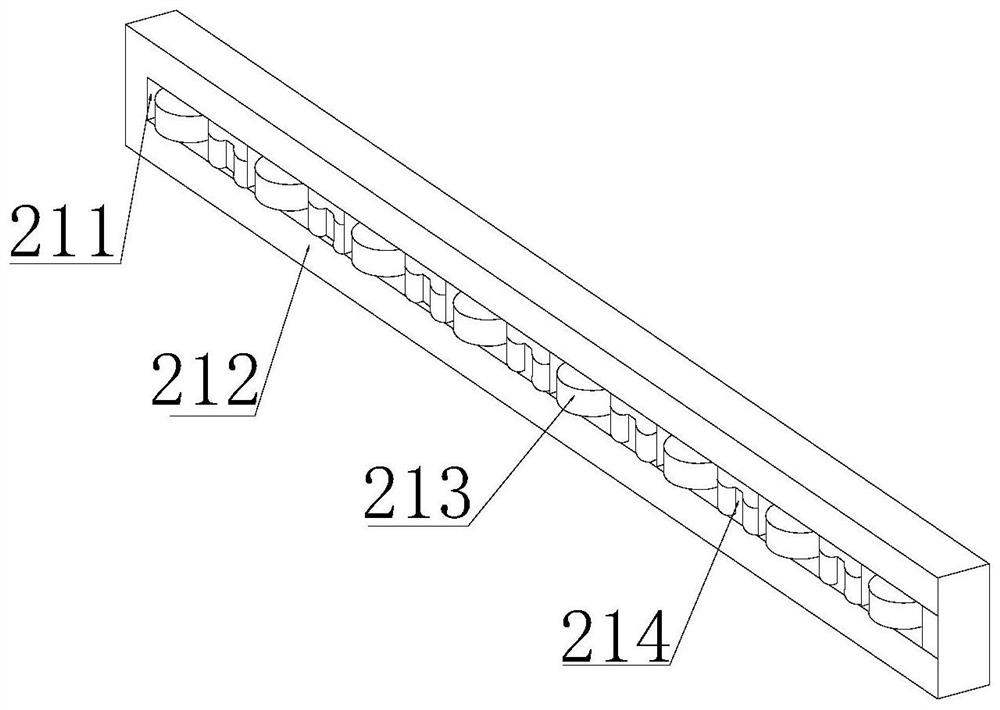

[0034] Wherein, the guide 213 includes a pulley a1, a block a2, an elastic rubber block a3, a pad a4, and an extruding rod a5. The pulley a1 is movably matched with the top end of the extruding rod a5. The outer surface is clearance fit, the pad a4 is integrally nested and connected with the extruding rod a5, the end of the extruding rod a5 is in interference fit with the elastic rubber block a3, and the clamping block a2 is fixed on the left and right sides of the extruding rod a5 Snap-fit connection, the pad a4 is in the shape of a "crescent moon" as a whole, and there are eight pieces in total, which are distributed on the inner side of the pulley a1 to fit with the gap, and the elastic rubber block a3 is conducive to exhaust and suction through its own holes, and is squeezed After the rod a5 is extruded, the internal air is discharged, and when it is not under pressure, the air is slowly inhaled to return to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com