Tool assembly for assisting in mounting elastic parts and elastic part mounting method

A technology of installation flexibility and installation method, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems such as time-consuming, labor-intensive, low work efficiency, and inconvenient installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

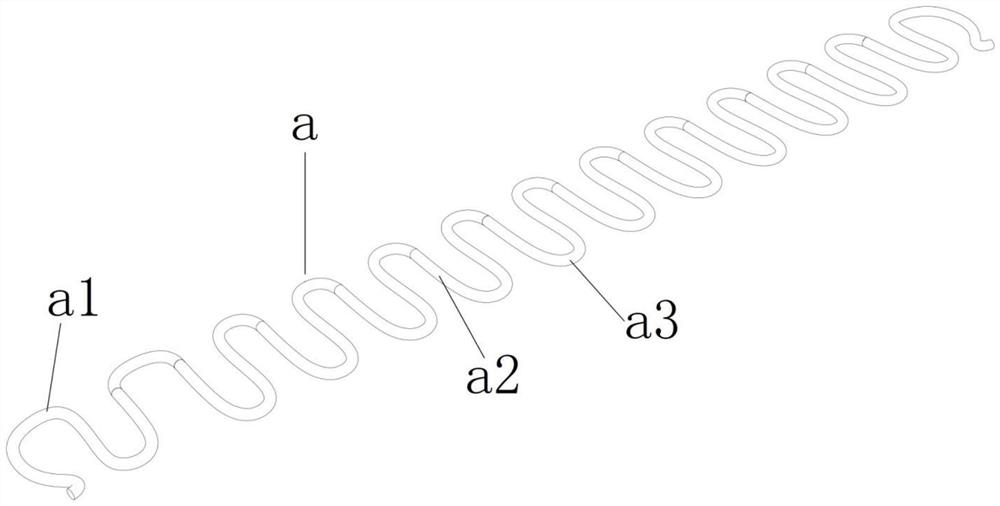

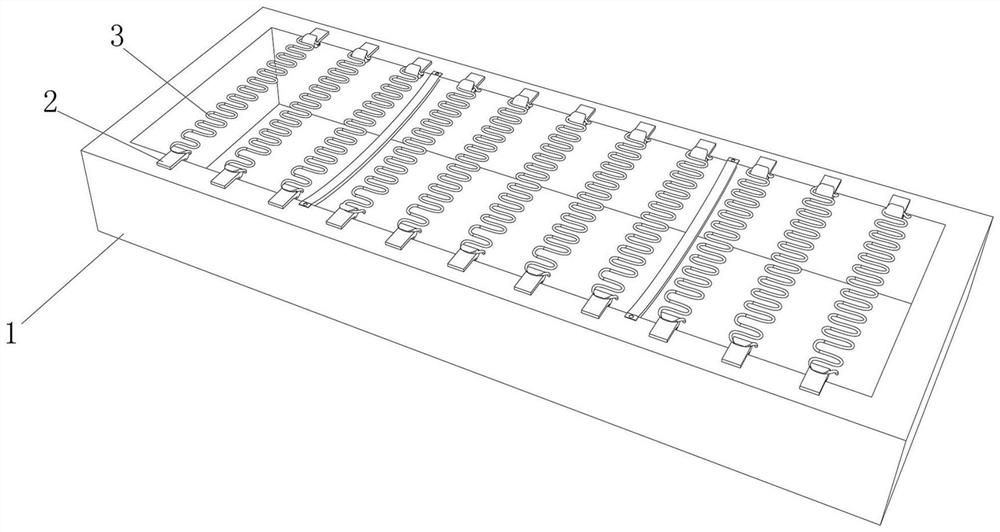

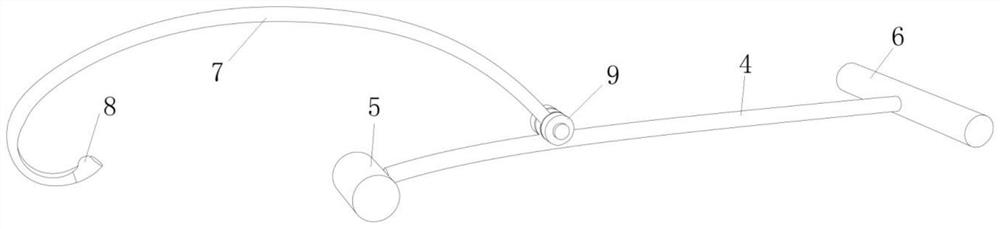

[0037] Referring to Figures 1 to 1 of the accompanying drawings in the description of the present invention Figure 7 As shown, according to a preferred implementation of the present invention, a tooling assembly for auxiliary installation of elastic members is described, the tooling assembly for auxiliary installation of elastic members 3 includes the tooling assembly including a support member 4 and a hook and pull member 7, the hook One end of the pulling member 7 is a hook-shaped structure, and the other end is hinged to the body of the supporting member 4; one end of the supporting member 4 is provided with a handle 6, and the other end is a supporting end 5 that provides a supporting point when the hook is pulled. The first distance value between the hinge point of the hook and pull member 7 and the support member 4 and the handle 6 is greater than the second distance value between the hinge point and the support end 5; in this embodiment, the elastic member 3 specificall...

Embodiment 2

[0042] This embodiment also provides a method for installing an elastic member, which is implemented by using the tooling assembly described in the first embodiment; specifically, the following steps are included:

[0043] Step 1: Hang the first end hook portion a1 of each elastic piece 3 in the rubber buckle 2 on the top of one end of the wooden frame 1;

[0044] Step 2: Hold the handle 6 with your hand, hook the hook-shaped end of the hook pulling member 7 to the second linear segment a2 at the end of the elastic member 3, and the supporting end 5 is against the side wall of the other end of the wooden frame 1 superior;

[0045] Step 3: With the contact point between the support end 5 and the side wall of the other end of the wooden frame 1 as the center, press the handle 6 downward, the support member 4 rotates around the contact point, and the elastic member 3 is deformed and elongated, so that the elastic member The end hook of 3 is hung on the rubber buckle 2 on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com