Box girder support system construction process

A technology of support system and construction technology, which is applied in the direction of bridges, bridge materials, bridge construction, etc., can solve problems affecting project quality and construction quality, etc., to improve project quality, eliminate inelastic deformation, improve construction safety and project quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: A kind of box girder support system construction technology, comprises the following steps:

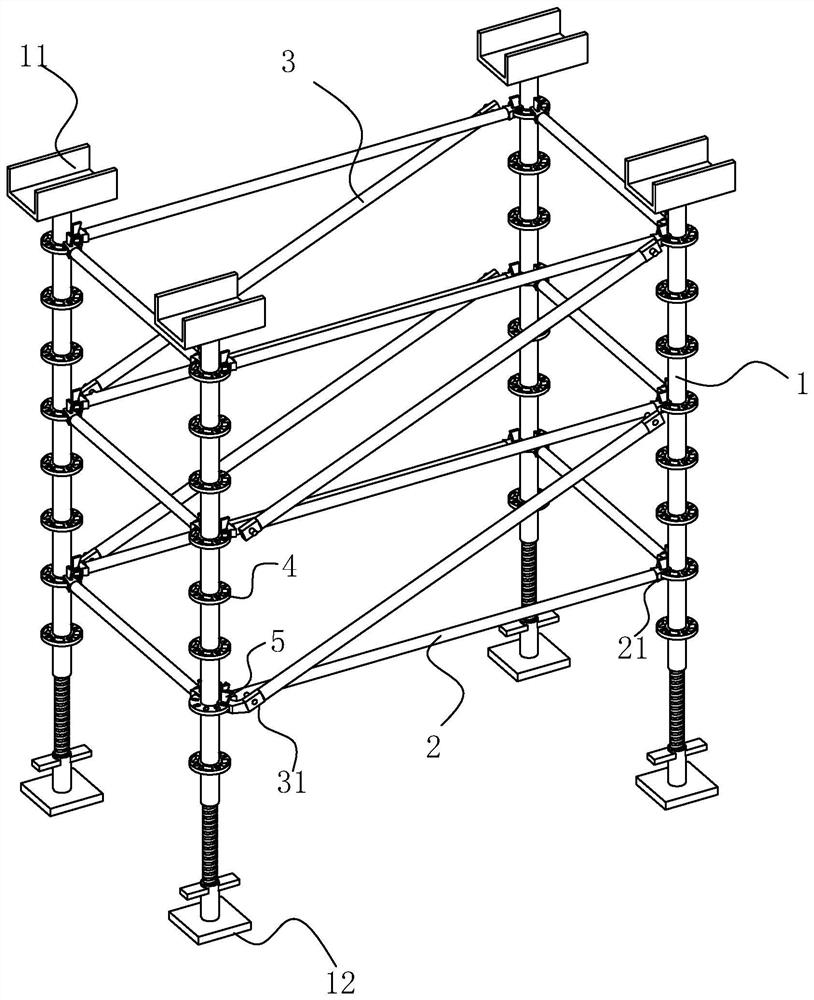

[0034] Step 1: erection of cast-in-place box girder brackets. Box girder brackets at different positions adopt different erection methods. Common erection methods include full-panel buckle-type bracket structure and door-hole type bracket structure.

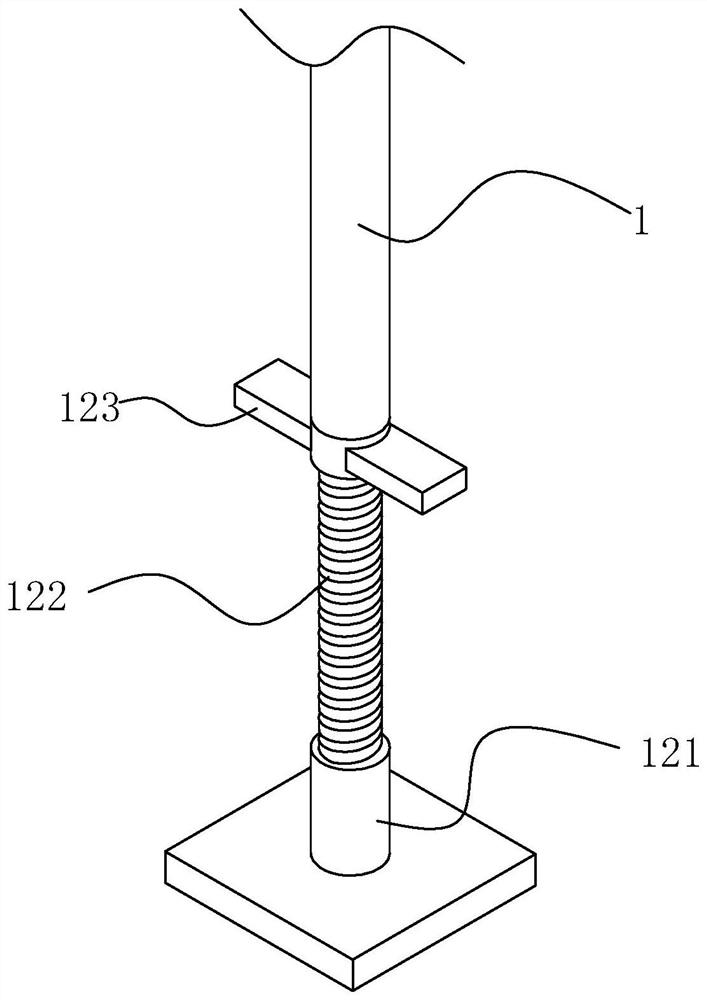

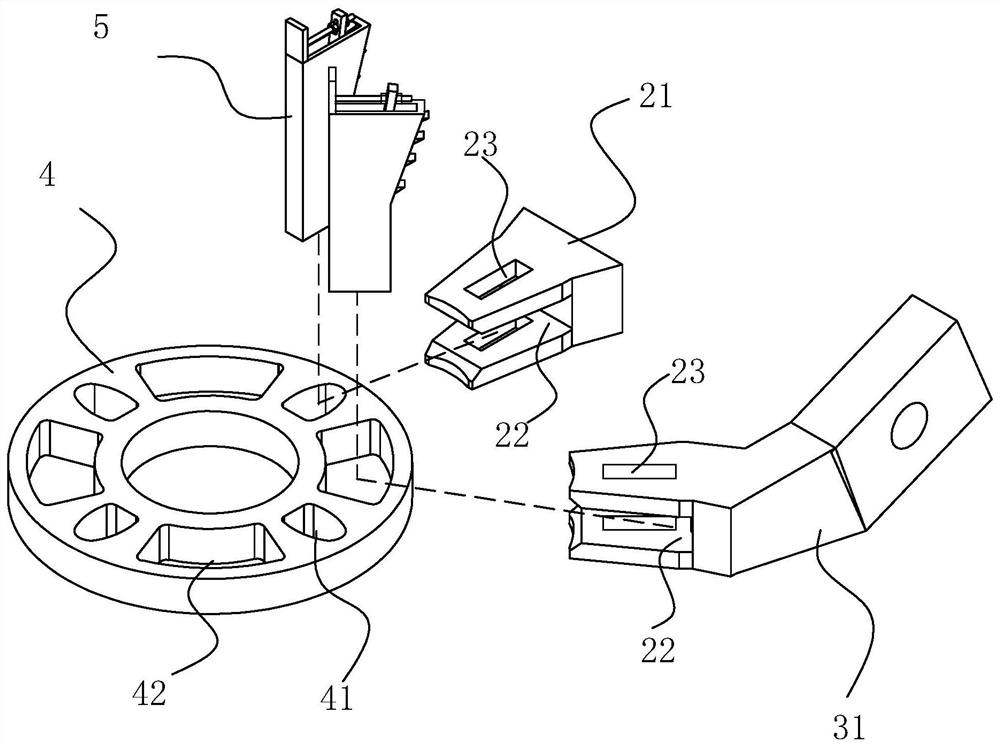

[0035] A box girder bracket, see figure 1 , comprising a vertical bar 1, a horizontal bar 2, an oblique bar 3, a disc fitting 4 and a latch 5. The disc fitting 4 is plugged on the pole 1, moved to a fixed position and fixed by welding, and the axis of the disc fitting 4 coincides with the axis of the pole 1. Both ends of the horizontal bar 2 are fixed with a first plug 21 connected to the disc fitting 4 , and both ends of the oblique bar 3 are fixed with a second plug 31 connected with the disc fitting 4 . Both the first plug 21 and the second plug 31 are plugged into the disk fitting 4 and fixed by the pin 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com