Micro-mirror structure and manufacturing method thereof, micro-mirror array and detector

A manufacturing method and micromirror technology, which are applied in the field of micromirror arrays and detectors, can solve the problems of increasing the difficulty of control and meeting the wide range of requirements for the deflection direction of the micromirror, and achieve simple structure, precise and convenient angle control, and satisfy multiple requirements. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

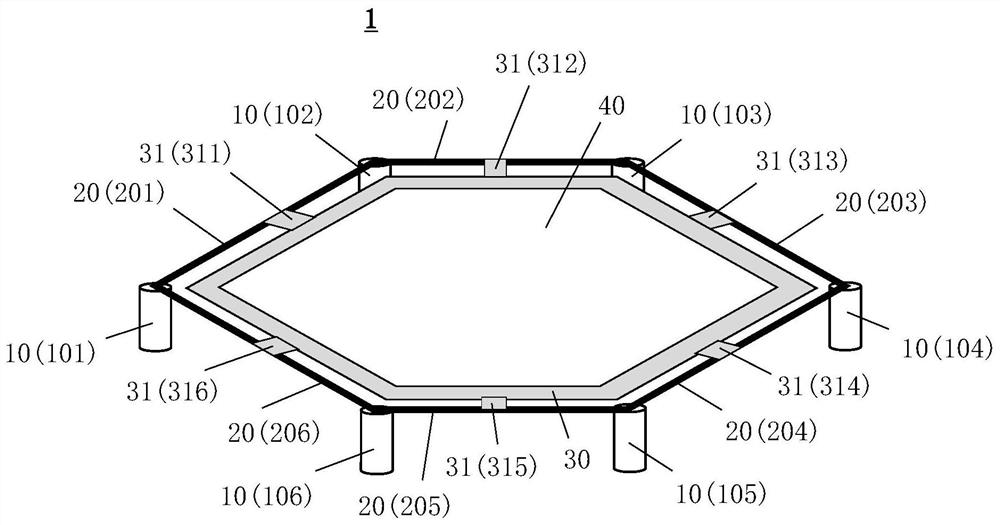

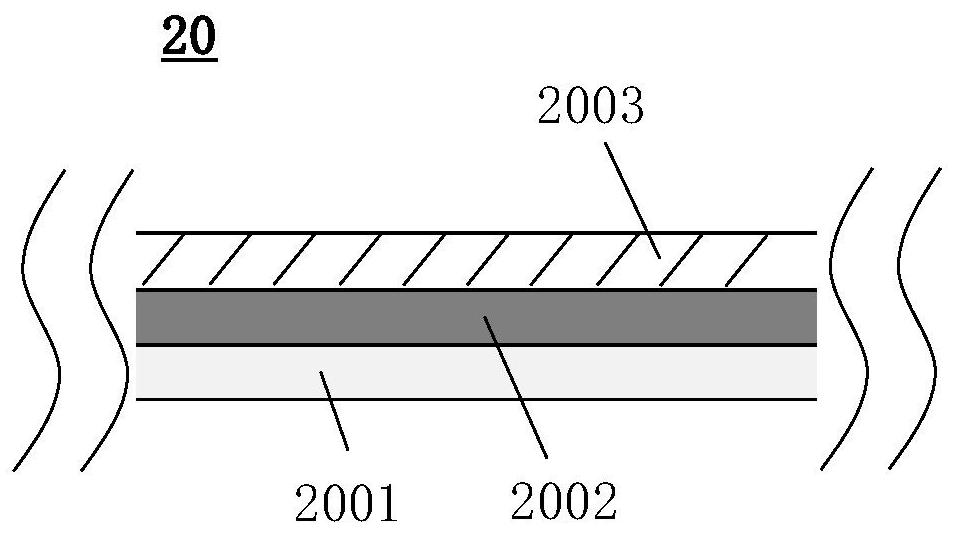

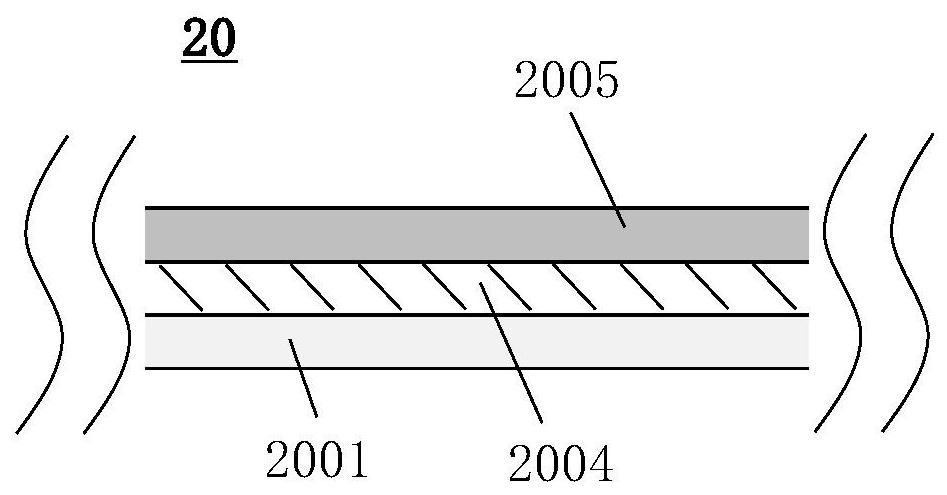

[0037] The core idea of the present invention is that the present invention provides a hexagonal micromirror structure, using a six-section deformable beam structure that can produce bending deformation after being energized and heated, as a power mechanism for driving the deflection of the hexagonal micromirror (light reflection film) , and the displacement of the side can be controlled in sections from different sides of the six sides of the micromirror, so the present invention can be used to deflect the micromirror towards any predetermined direction, and can also control the micromirror as a whole in the vertical direction Floating on the surface, which greatly meets the various requirements for the deflection (movement) direction of the micromirror in different application scenarios. Compared with complex deflection control structures such as the comb structure in the prior art, the present invention uses six deformable beam structures to adjust the deflection angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com