Socket

A technology of sockets and plugs, which is applied in the direction of electrical components, coupling devices, circuits, etc., and can solve problems such as damage to electrical equipment, electric shock to staff, and large fluctuations in socket current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

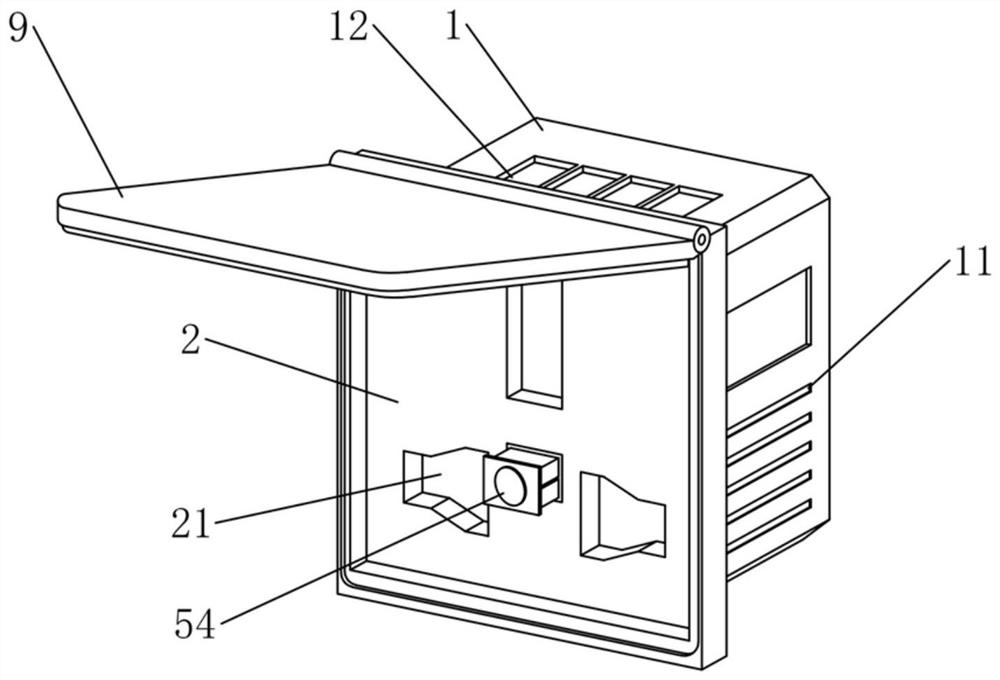

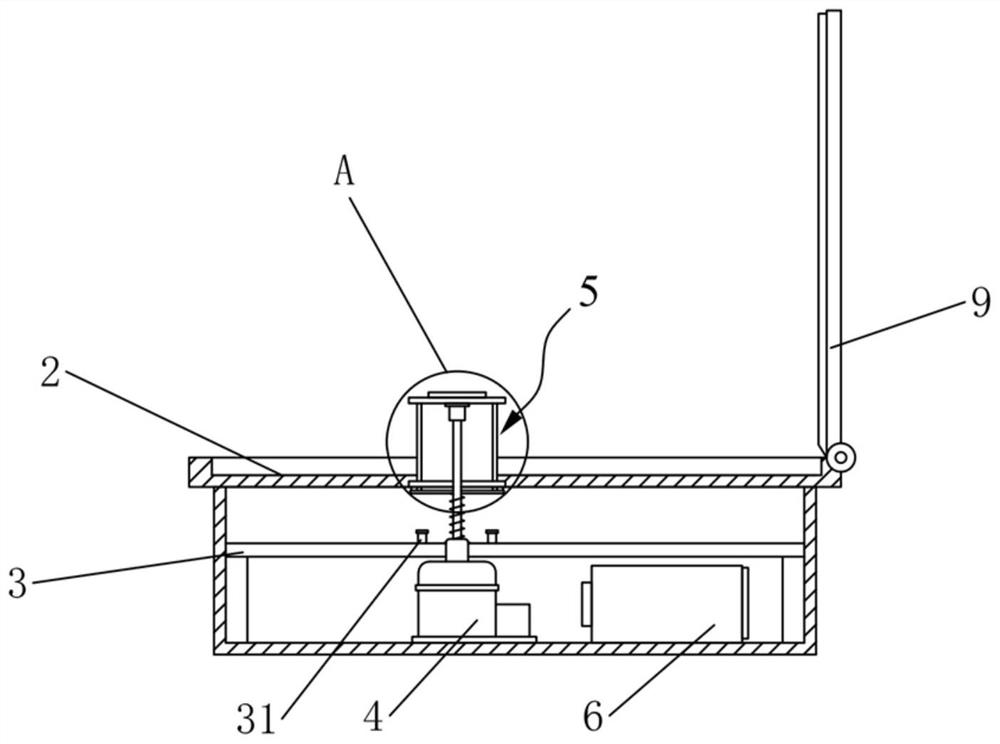

[0042] This embodiment provides a socket, which is used to supply power to or cut off power for electric equipment, so as to improve the safety of electric equipment.

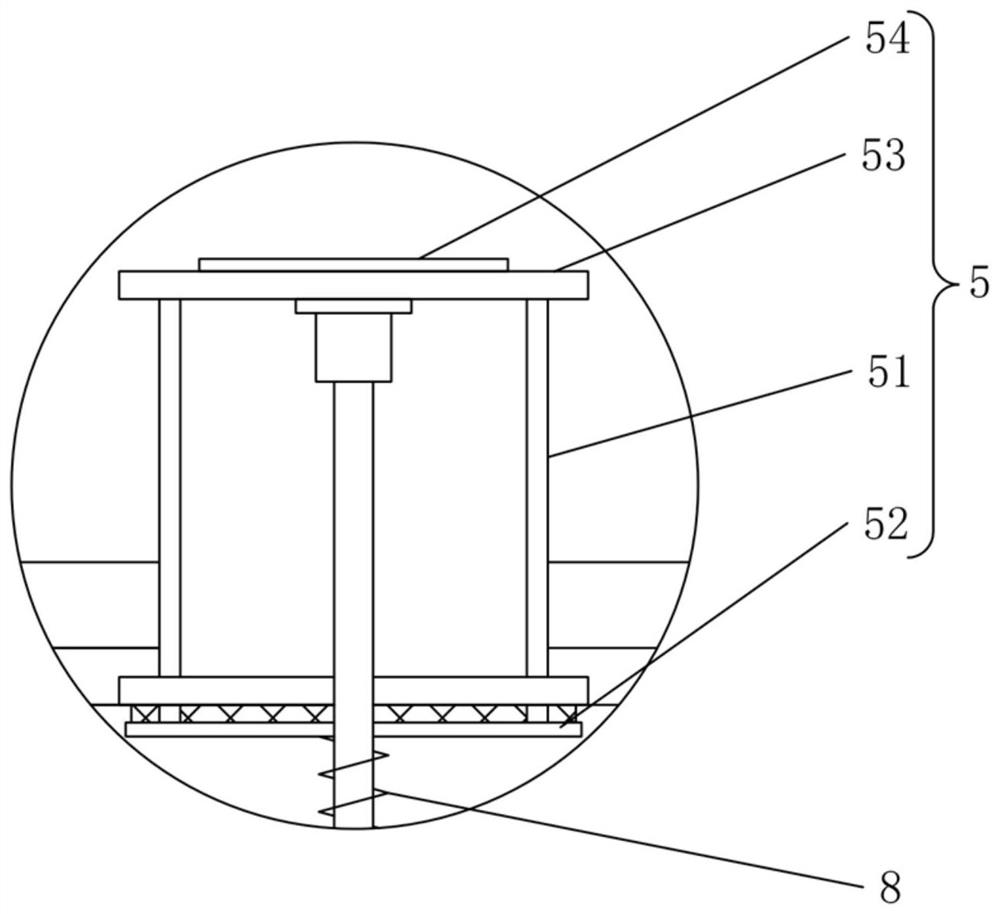

[0043] Such as figure 1 and figure 2 As shown, the socket provided in this embodiment includes a socket body 1 , a first plate 2 , a thrust mechanism and a current sensor 6 . Wherein, the socket main body 1 has a receiving groove, and the first plate 2 covers the opening of the receiving groove, and the plug of the electrical equipment passes through the first plate 2 and is electrically connected to the power module of the device main body 1 . The push mechanism includes an electromagnetic push rod 4 and a pop-up assembly 5, the electromagnetic push rod 4 is arranged in the receiving groove, the pop-up assembly 5 is connected to the output end of the electromagnetic push rod 4, and the pop-up assembly 5 slides through the first plate 2, To switch between the ejection position and the avoidance position, whe...

Embodiment 2

[0057] Such as figure 1 As shown, the socket of the second embodiment is basically the same as that of the first embodiment above. The difference between the two is that the socket also includes cooling holes 11, which can prevent the socket from being overheated during use and causing danger.

[0058] Specifically, the cooling hole 11 is provided on one side of the socket main body 1 to dissipate the heat of the socket and prevent the internal temperature of the socket from being too high.

[0059] Such as figure 1 As shown, in order to keep the dryness of the socket, preferably, one end of the first board 2 is rotatably connected with a board cover 9, and the board cover 9 can be rotated to cover the first board 2, and the first board 2 is blocked by the board cover 9 , can reduce the external environment such as the attachment and condensation of humid air on the first board 2, and keep the first board 2 dry for a long time. In order to ensure the tightness between the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com