Fertilizer application device for agricultural farmland cultivation

A technology for farmland and chemical fertilizer, applied in the agricultural field, can solve the problems of inability to quantitatively fertilize and adjust the depth of ploughing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

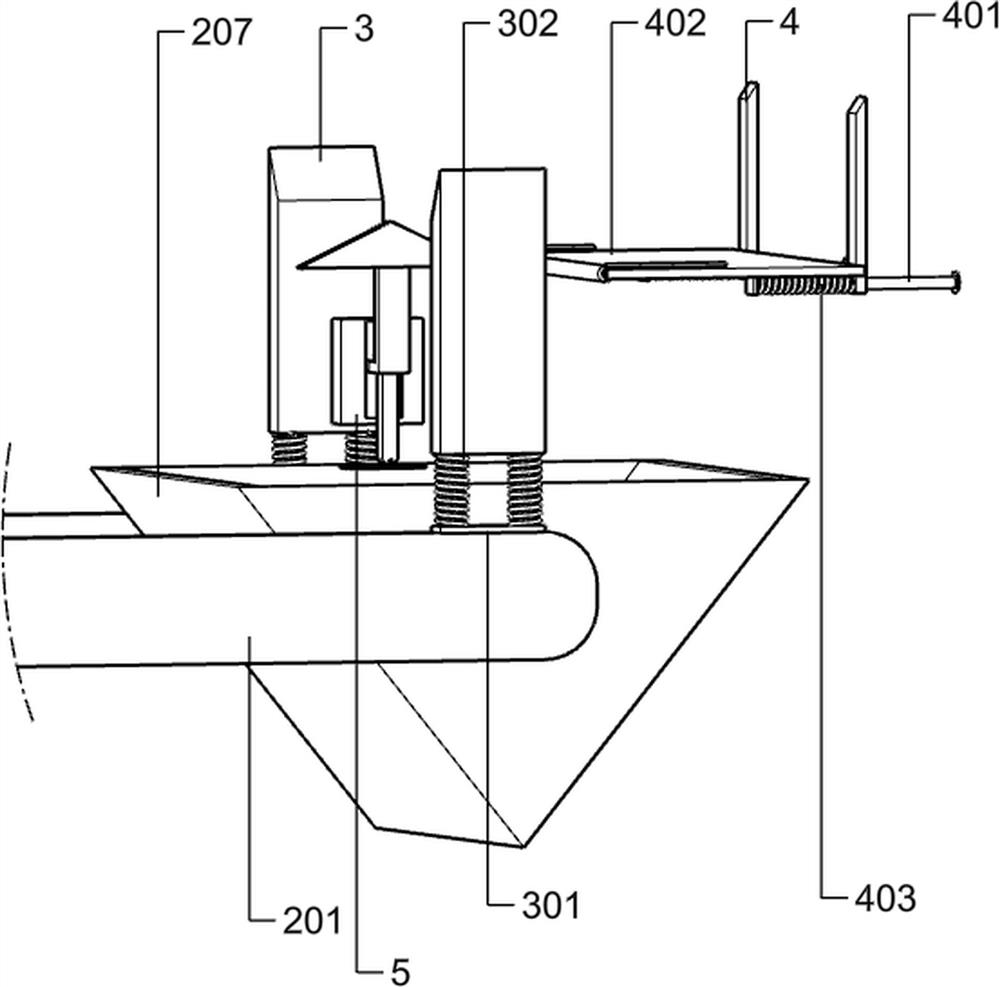

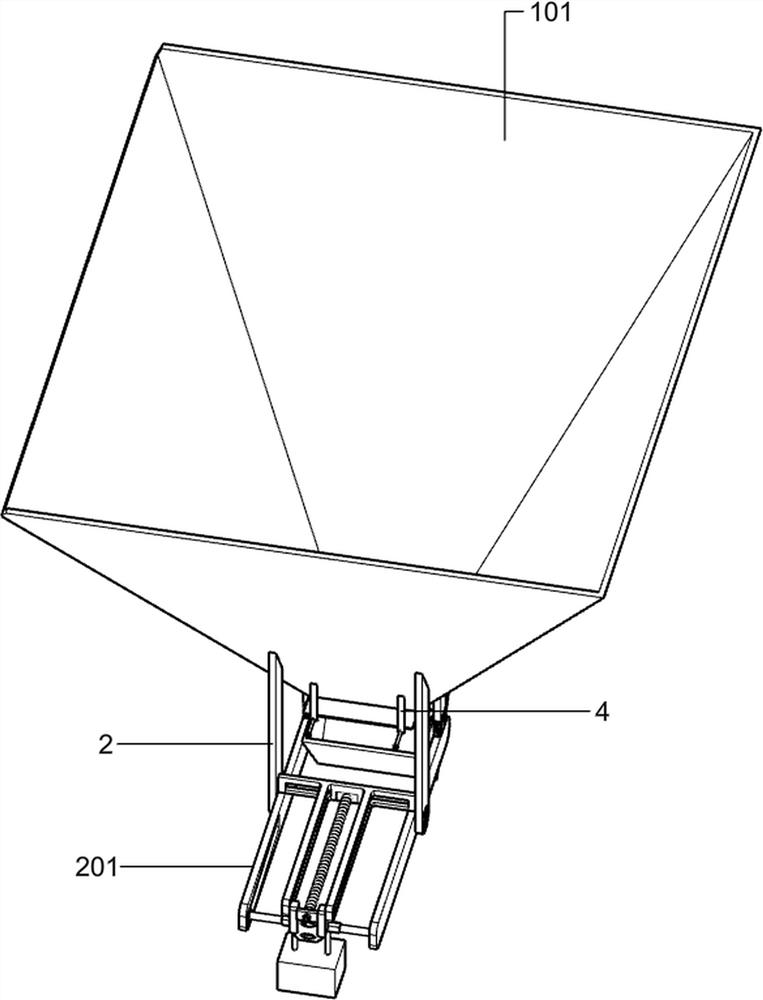

[0028] Applicable device for chemical fertilizers used in agricultural farmland cultivation, such as figure 1 As shown, it includes a vehicle frame 1, a hopper 101, a wheel 102, a control assembly, a trigger assembly and a dodge door assembly. Two groups of wheels 102 are arranged on the front and rear sides of the bottom of the vehicle frame 1, the hopper 101, the control assembly, the trigger assembly, There are three groups of dodge door assemblies and are arranged on the vehicle frame 1 at intervals. The hopper 101 is arranged in the middle part of the vehicle frame 1. A control assembly is arranged on the lower side of the hopper 101. The parts of the control assembly are fixedly connected on the hopper 101. The dodge door The assembly is arranged at the bottom of the hopper 101, the trigger assembly is fixedly connected to the control assembly, and the trigger assembly is in sliding contact with the movable door assembly.

[0029] Pour the chemical fertilizer into the ho...

Embodiment 2

[0031] On the basis of Example 1, such as figure 2 As shown, the control assembly includes a vertical support plate 2, a horizontal support plate 201, a column 202, a counterweight 203, a connector 204, a T-shaped slider 205, an adjustment screw 206, a blanking funnel 207 and a buffer assembly. The upper end of the support plate 2 is fixedly connected to the outer wall of the hopper 101, the lower end of the vertical support plate 2 is rotatably connected with the horizontal support plate 201, the column 202 is slidingly connected in the groove on the horizontal support plate 201, and the counterweight 203 Rotationally connected to the middle of the cylinder 202, the T-shaped slider 205 is fixedly connected to the upper side of the horizontal support plate 201, the connector 204 is slidably connected to the groove of the T-shaped slider 205, and the left front end of the connector 204 is fixed with a counterweight Block 203, the adjusting screw rod 206 passes through the conn...

Embodiment 3

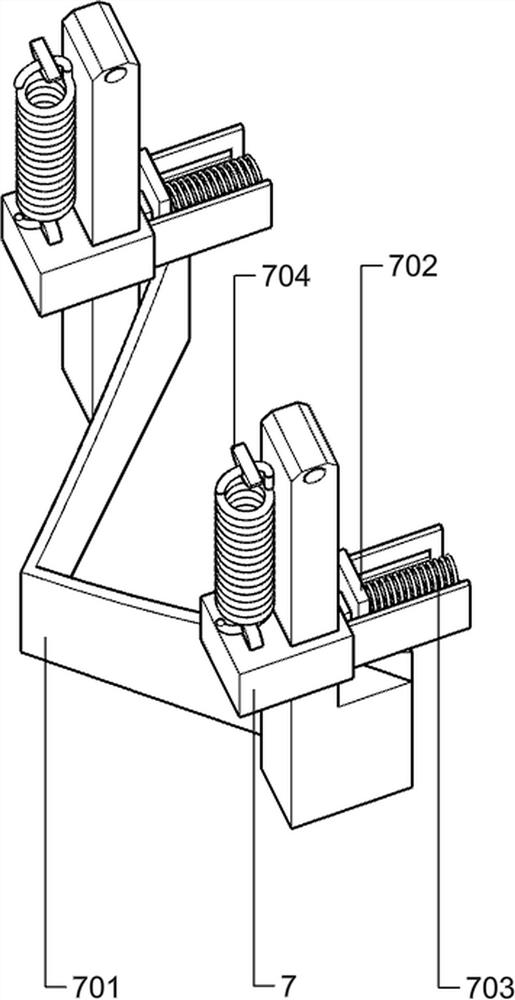

[0038] On the basis of Example 2, such as Figure 5 with image 3 As shown, the trigger assembly includes a square shell 5, a sliding column three 501, a push rod 502, a spring three 503, a roller 504 and a touch plate 505, the outer side of the square shell 5 is fixedly connected to the vertical support plate one 2, and the sliding column three 501 is fixedly connected to the inner bottom side of the square shell 5, the ejector rod 502 is slidably connected to the sliding column 3 501, the spring 3 503 is sleeved on the sliding column 3 501, and the lower end of the spring 3 503 is fixedly connected to the inner bottom side of the square shell 5, The upper end of the spring three 503 is in contact with the push rod 502, the lower end of the push rod 502 is rotatably connected with a roller 504, the outside of the touch plate is fixedly connected on the inner wall of the blanking funnel 207, and the touch plate 505 is in contact with the roller 504; the movable door assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com