Automatic feeding device for pelteobagrus fulvidraco culture

An automatic feeding and yellow catfish technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems that yellow catfish are easy to scramble, easy to waste, and can't finish eating yellow catfish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

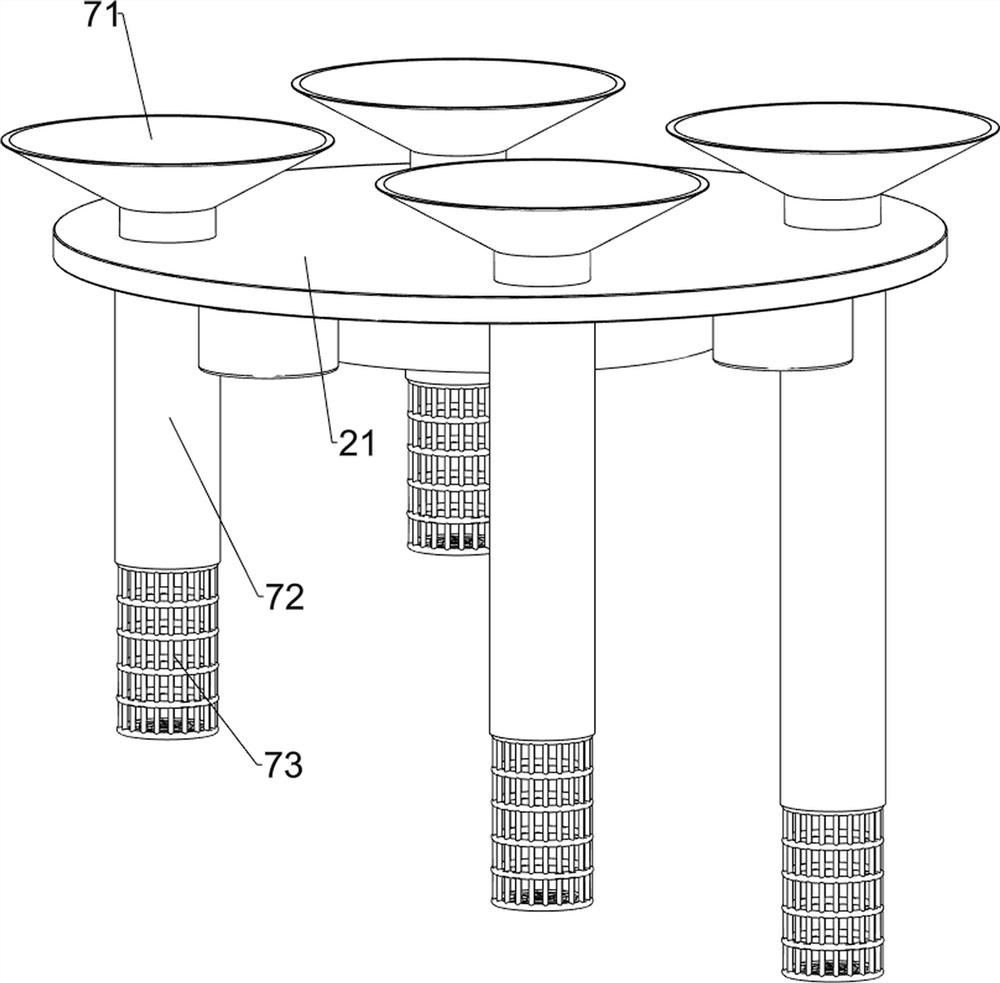

[0054] A kind of automatic feeding device for cultivating yellow catfish, such as figure 1 As shown, it includes a traction rope 1, a floating mechanism 2 and a storage mechanism 3. One end of the traction rope 1 is connected with a floating mechanism 2, and the floating mechanism 2 is provided with a storage mechanism 3.

[0055] Such as figure 2 As shown, the floating mechanism 2 includes a floating plate 21, a counterweight 23 and a floating ring 24. One end of the traction rope 1 is connected to the floating plate 21, and the floating plate 21 is evenly opened with a first through hole 22, and the bottom of the floating plate 21 is evenly distributed around the bottom. A counterweight 23 is provided, and a floating ring 24 is provided in the middle of the bottom of the floating plate 21 .

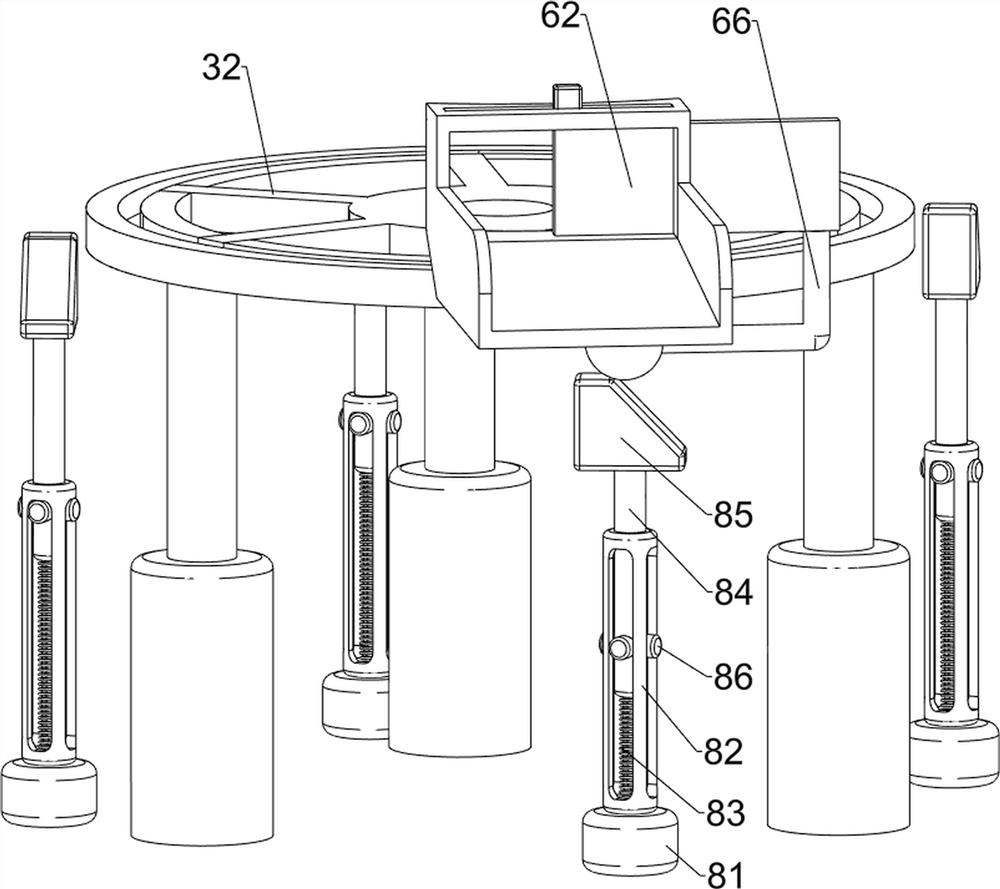

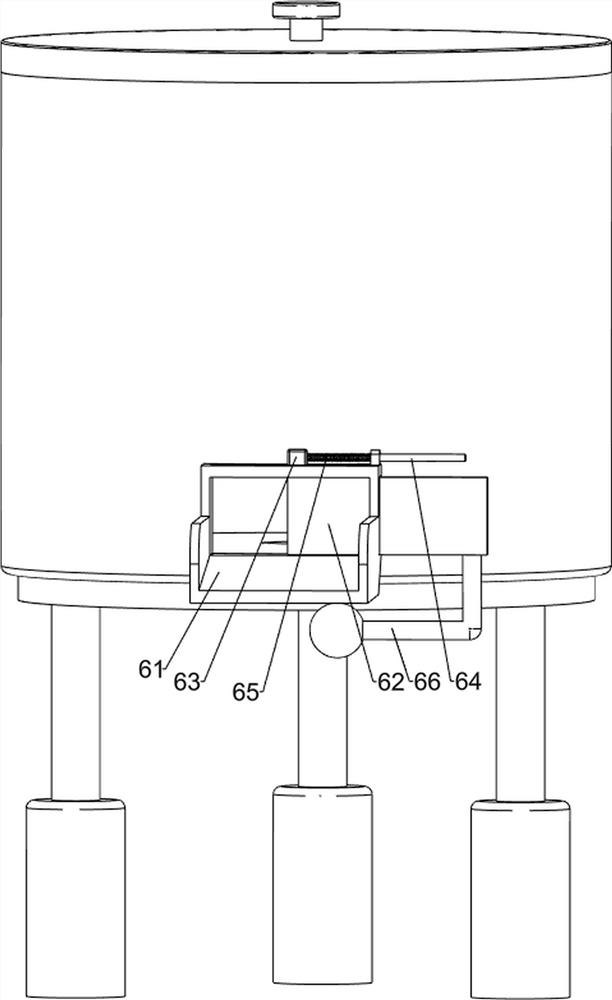

[0056] Such as image 3 As shown, the storage mechanism 3 includes a mounting column 31, a mounting plate 32, a storage box 33, a cover plate 34, a torsion spring 35 and a handle 36,...

Embodiment 2

[0059] On the basis of Example 1, such as Figure 4 As shown, a driving mechanism 4 is also included, and the driving mechanism 4 includes a motor 41, a first gear 42, a first rotating shaft 43 and a second gear 44, a motor 41 is arranged in the middle of the top of the floating plate 21, and the output shaft of the motor 41 is connected to a second gear. A gear 42, the first rotating shaft 43 is provided with the rotating type in the middle part of the floating plate 21, and the first rotating shaft 43 passes through the mounting plate 32 and cooperates with its rotating type. There is a second gear 44 which meshes with the first gear 42 .

[0060] Such as Figure 4As shown, a stirring mechanism 5 is also included. The stirring mechanism 5 includes a second rotating shaft 51, a boss 52 and a fan blade 53. The first rotating shaft 43 is connected with a second rotating shaft 51, and the top of the second rotating shaft 51 is provided with a boss 52. , the outside of the boss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com