Method for achieving automatic pressure leveling of wide and thick plate

A wide and thick plate, automatic technology, applied in the field of automatic pressure leveling of wide and thick plates, can solve the problem that the stroke of the flattener or the flattening force cannot be accurately calculated, and achieve the effect of a high degree of automation and a simple implementation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The objects and functions of the present invention and methods for achieving the objects and functions will be clarified by referring to the exemplary embodiments.

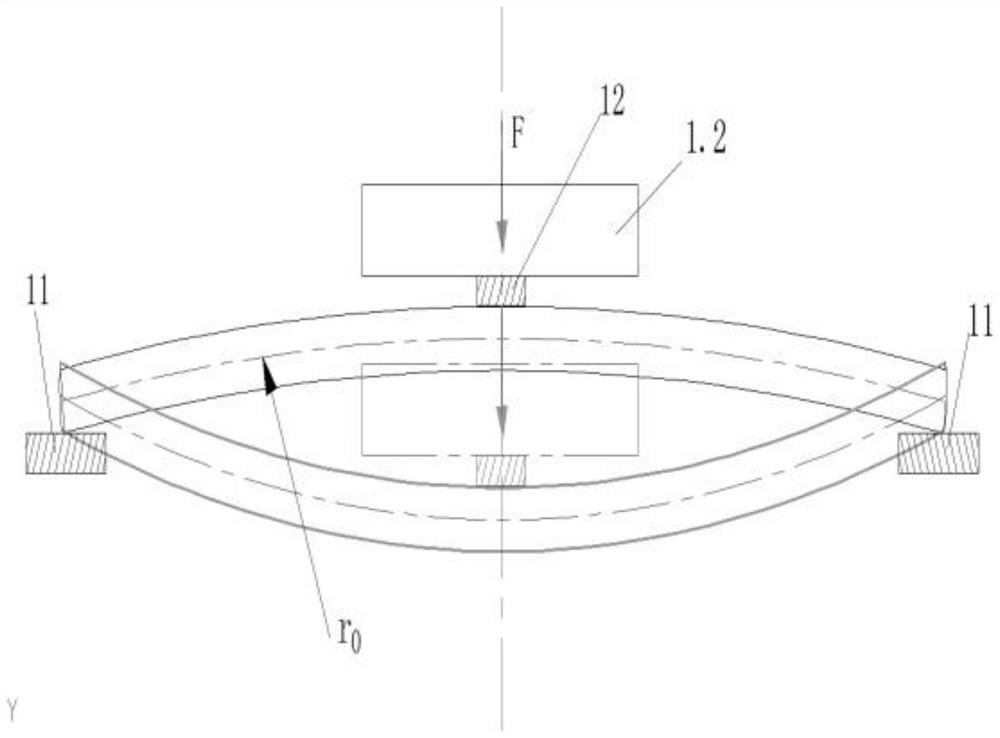

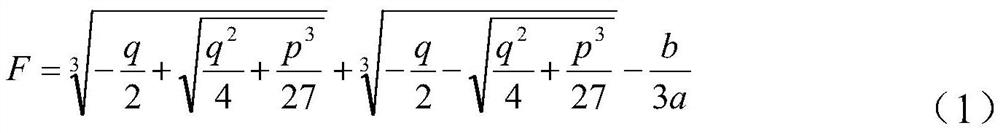

[0037] The invention provides a mathematical model of pressure leveling force based on the original bending curvature and material characteristic parameters, aiming at one-time leveling, and provides a method to realize automatic pressure leveling of wide and thick plates with the mathematical model of pressure leveling force as the core. method, including the following steps:

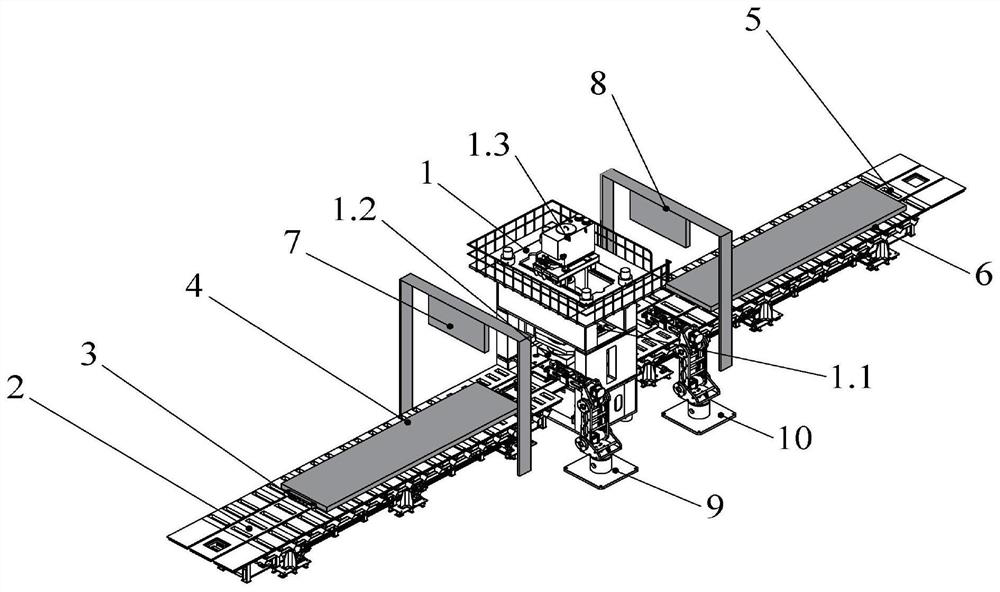

[0038] (1) Place the flat plate 4 to be pressed on the front roller table 2 in front of the main machine 1 of the flattening machine by driving in the workshop, and at the same time obtain relevant information about the flat plate 4 to be pressed, including elastic modulus E, yield strength σ s , sheet metal width w and thickness h;

[0039] (2) The front plate pushing device 3 behind the front roller table 2 pushes the plate 4 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com