Resistance-increasing oil extraction device capable of improving utilization rate of injected gas and manufacturing method thereof

A technology for injecting gas and oil production equipment, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., which can solve the problems of loss of injected gas energy, difficult to achieve plugging degree, and inability to prevent gas channeling itself, etc., to achieve Reduce gas channeling, reduce the occurrence of gas channeling, and improve oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

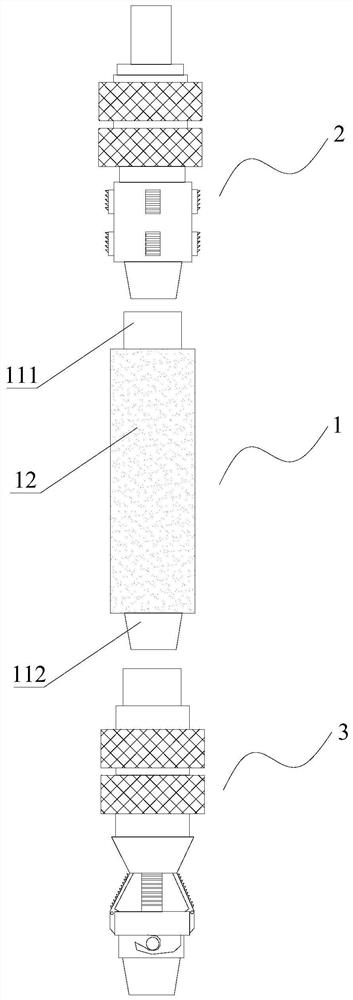

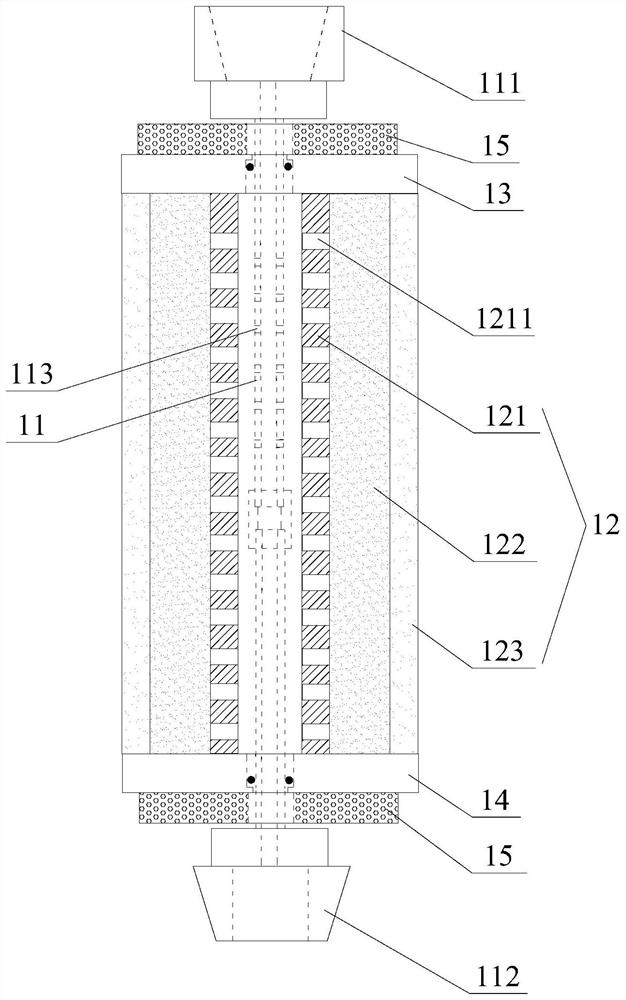

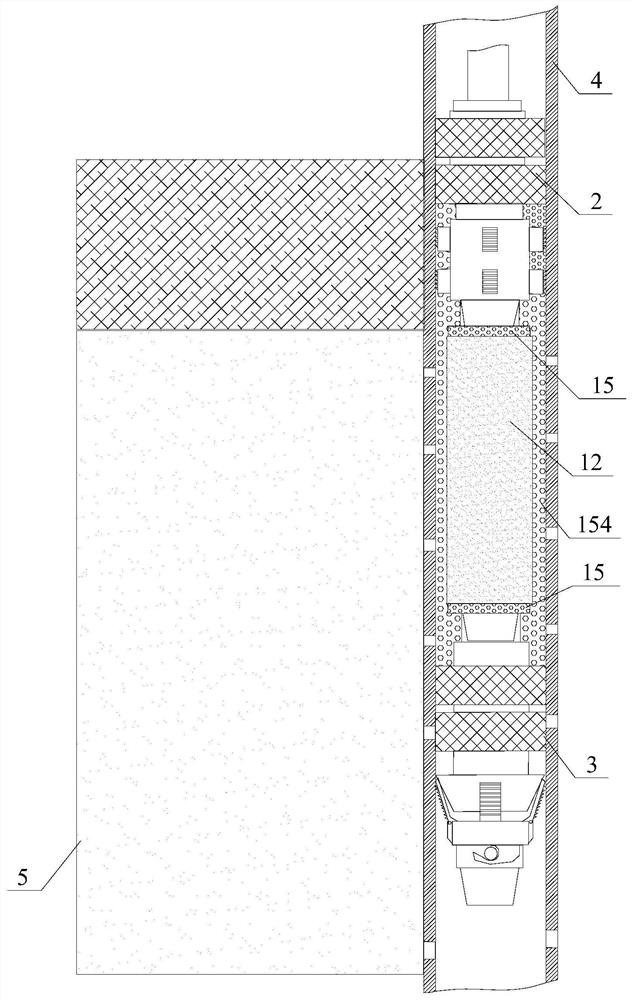

[0092] Such as Figure 1 ~ Figure 4 As shown, the present invention also provides a resistance-increasing oil recovery device that improves the utilization rate of injected gas, which can also be called "a well wall resistance-increasing device suitable for gas injection development", specifically refers to providing a device installed in The inner wall of the oil well casing of the oil production well can increase the pressure of the product in the oil layer to seep into the oil production well, so that the gas injected into the oil layer can gather inside the oil layer, maintain the pressure in the oil layer, and reduce the phenomenon of gas channeling, that is, to improve the injection Utilization rate of gas in oil reservoir;

[0093] The resistance-increasing oil production device for improving the utilization rate of the injected gas is arranged at the position where the interior of the oil production well 4 communicates with the oil layer 5, so as to increase the oil se...

Embodiment 2

[0116] Such as Figure 12 As shown, the present invention also provides a method for manufacturing an augmented resistance oil recovery device that improves the utilization rate of injected gas, which is used to manufacture the enhanced resistance oil recovery device that improves the utilization rate of injected gas in Example 1, and improves the increase in the utilization rate of injected gas. Oil recovery devices include:

[0117] Manufacturing resistance increasing sleeve 12;

[0118] Install the resistance increasing sleeve on the connecting pipe 11;

[0119] The upper packer 2 is connected to the upper end of the connecting pipe 11, and the lower packer 3 is connected to the lower end of the connecting pipe 11.

[0120] Further, as Figure 13 As shown, the manufacturing method of the resistance-increasing oil recovery device provided by the present invention to improve the utilization rate of injected gas, wherein, manufacturing the resistance-increasing sleeve 12 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com