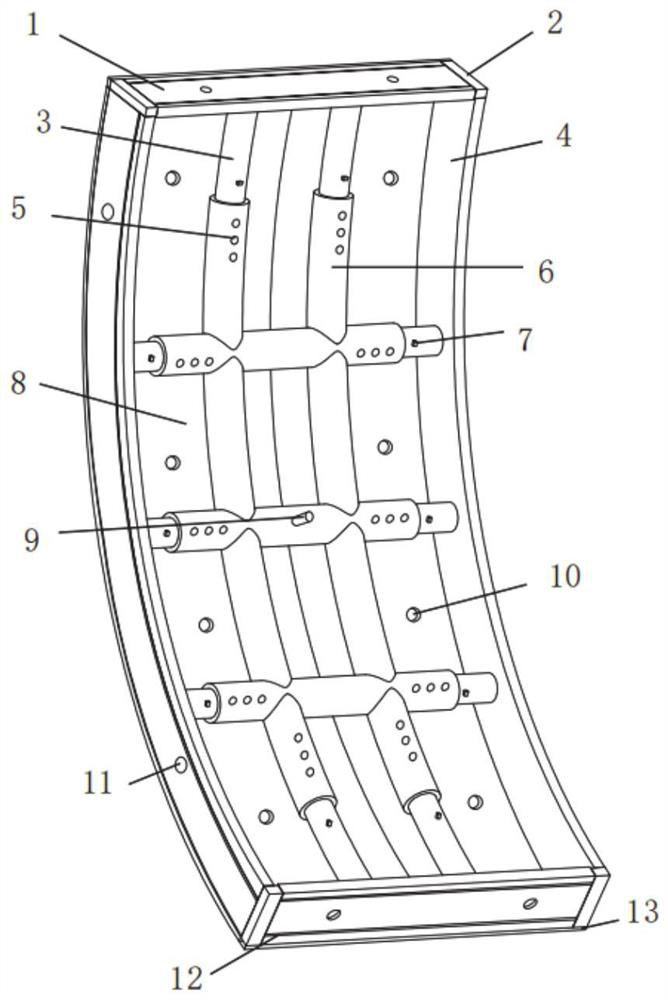

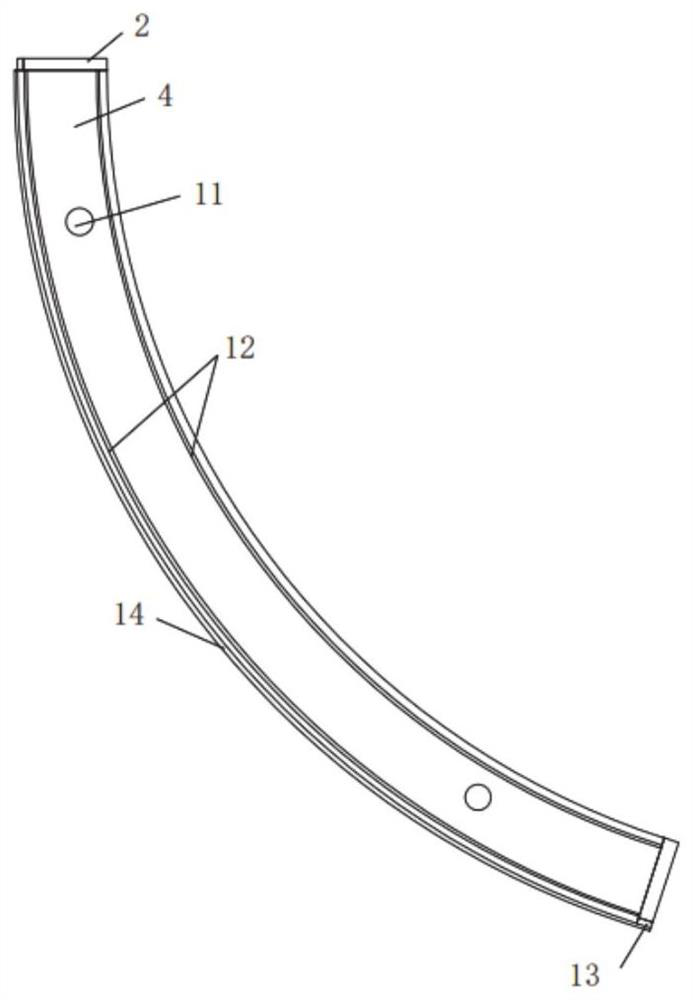

A telescopic steel pipe piece and its installation method for the construction of tunnel communication passages

A technology for communication channels and steel pipes, which is applied in tunnels, installation of anchor rods, tunnel linings, etc., can solve the problems of inability to reuse and difficult disassembly of segments, and achieve rapid disassembly and reuse, easy disassembly, enhanced integrity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0046] An embodiment of the present disclosure provides an assembly method based on the above-mentioned telescopic steel pipe sheet for construction of a tunnel communication channel, the method includes the following process:

[0047] The overall construction process of the segment is as follows:

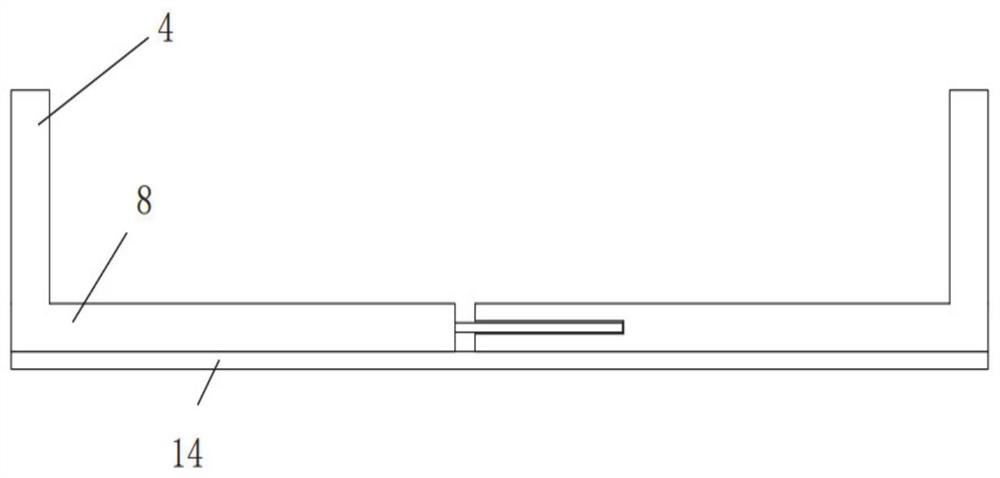

[0048] (1) Before the segment is installed, the bearing plate is extended

[0049] Before the segment is installed, pull the jacking steel pipes on the arc-shaped bearing plate and the rectangular bearing plate to make the rectangular bearing plate and the arc-shaped bearing plate protrude, and the external dimension of the stretched segment is consistent with the concrete prefabricated segment. The jacking steel pipe is fixed in the stressed steel pipe by the limit bolt, and at the same time, a PVC plastic plate is installed on the outside of the bottom bearing plate and a waterproof sealing strip is pasted around it, so as to prevent slurry leakage and later steel pipe pieces at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com