Profile steel inner support system joint

A support system and node technology, which is applied in excavation, construction, infrastructure engineering, etc., can solve the problems that H-shaped steel support nodes cannot fully exert the strength and ductility of steel, and achieve controllable construction quality, enhanced integrity and stability, The effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

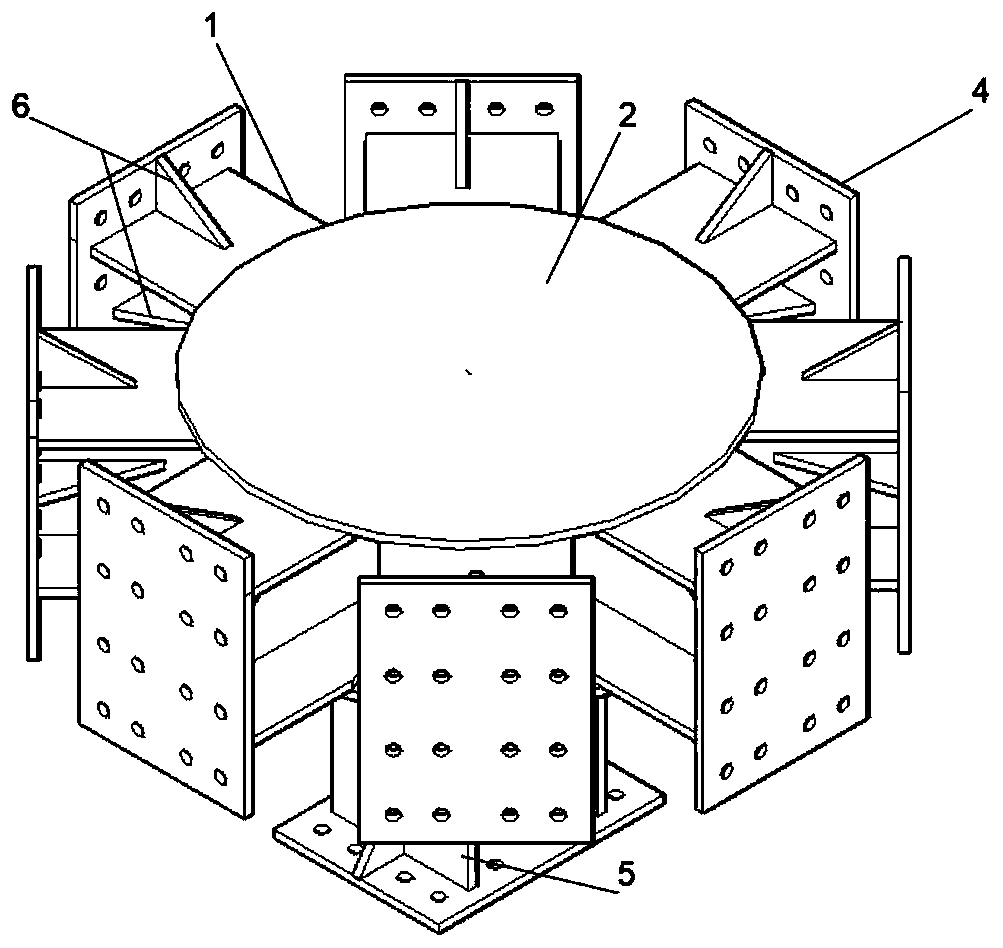

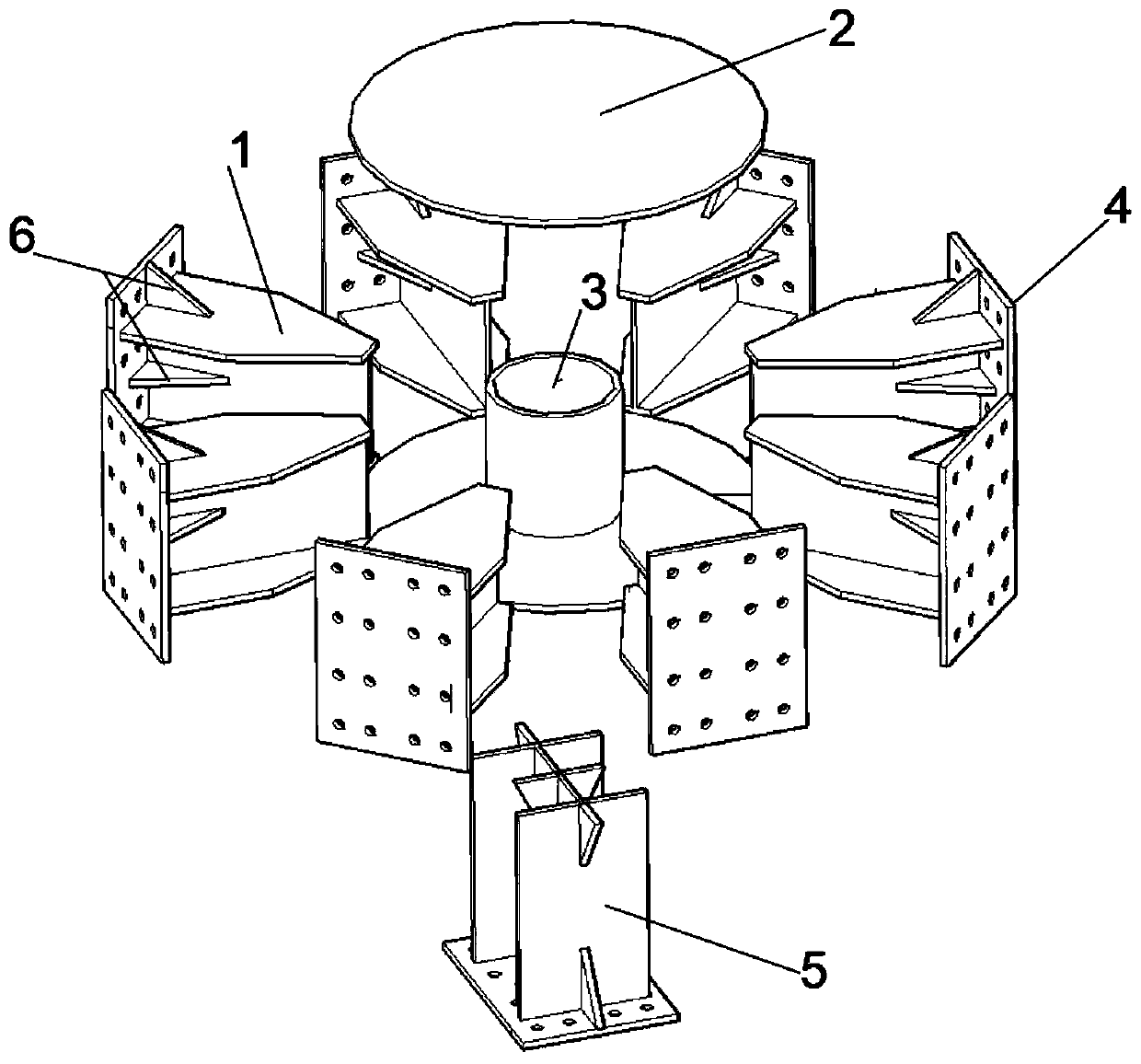

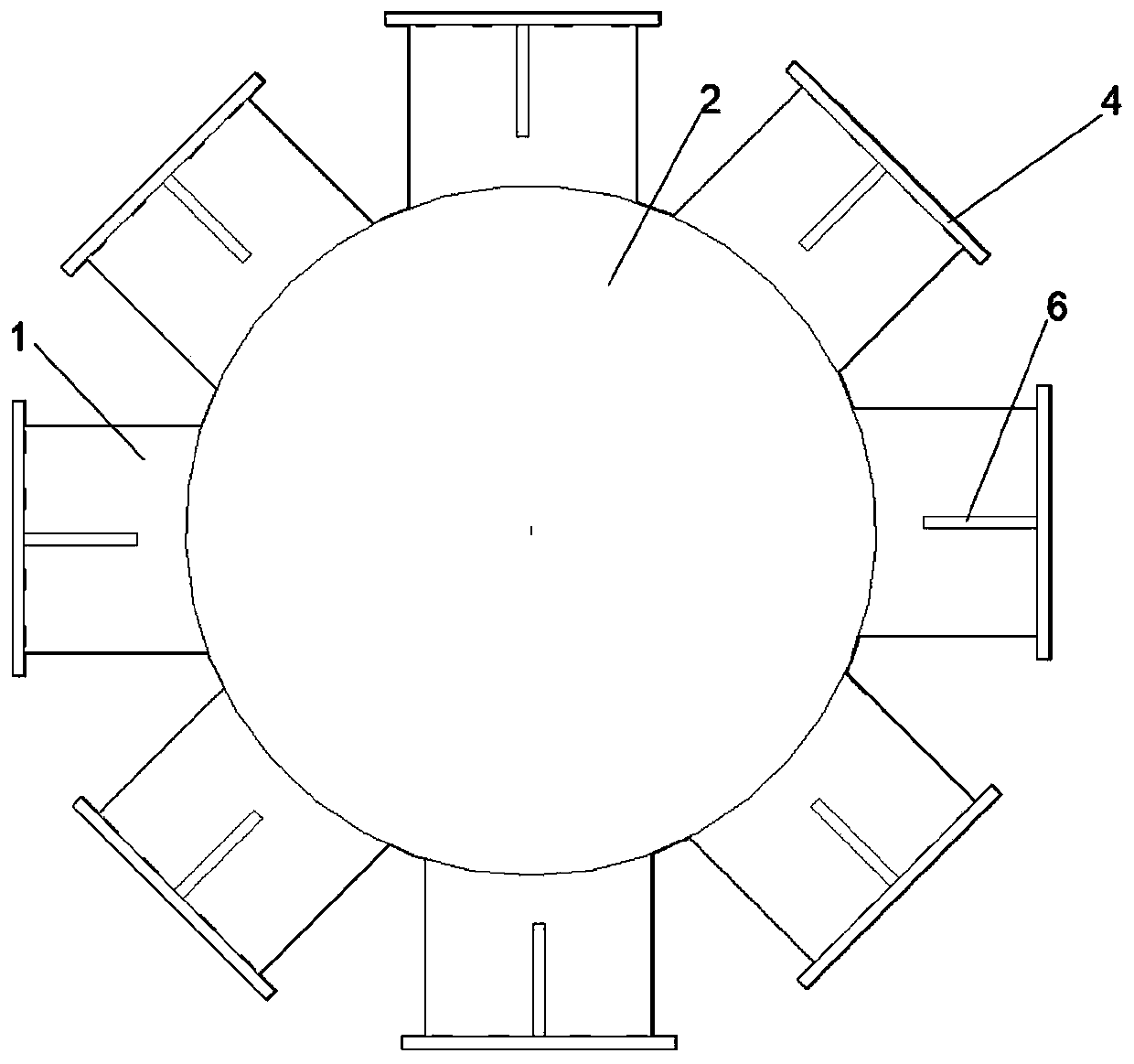

[0013] Such as Figure 1 to Figure 4 As shown, a steel internal support system node is used to connect vertical support and horizontal support. The node includes horizontal H-shaped steel 1, steel cover plate 2, central column 3, flange plate 4, vertical H-shaped steel 5, and stiffener 6. Among them, the central axis of the steel cover plate 2, the central axis of the central column 3, and the central axis of the vertical H-shaped steel 5 coincide; the horizontal H-shaped steel is arranged around the outer side of the central column; 1 connection; horizontal H-shaped steel 1 is simultaneously connected with 2 upper and lower steel cover plates and central column 3; central column 3 is simultaneously connected with several horizontal H-shaped steel 1 and 2 upper and lower steel cover plates; H-shaped steel ends are connected with flange plates.

[0014] Among them, the surface of the steel cover plate 2 and the surface of the central column 3 ring are connected by L-shaped gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com