A chain with variable pitch and large load

A large load, variable pitch technology, applied in the field of chains, can solve the problems of reducing the scope of application, the chain cannot be socketed and installed, and the chain pitch cannot be adjusted, so as to achieve the effect of increasing the scope of application and reducing the damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

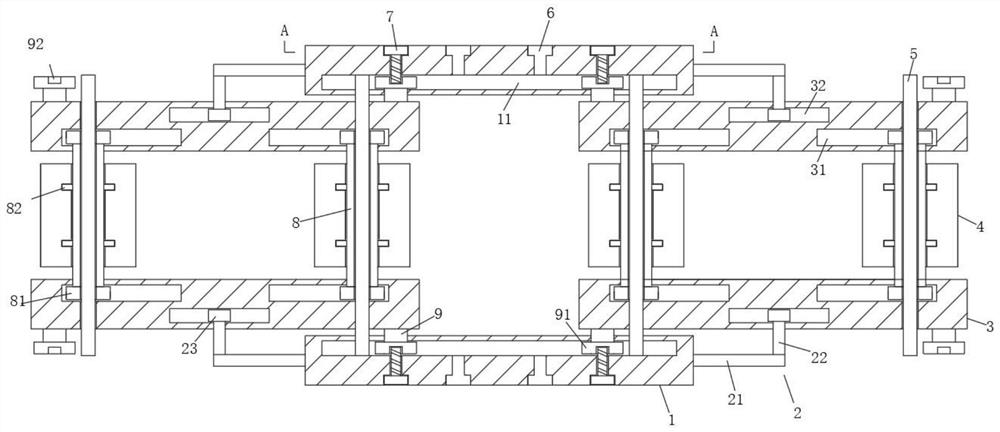

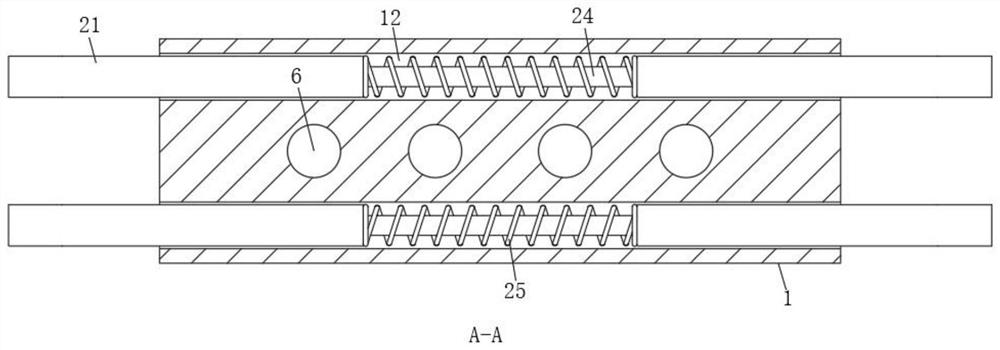

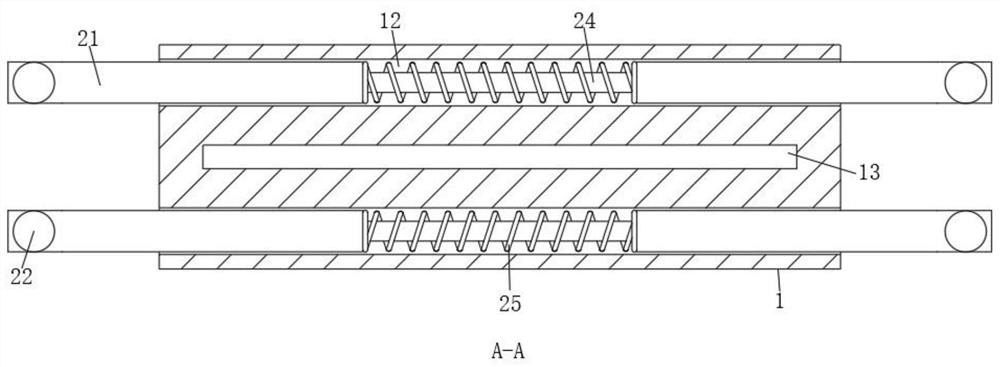

[0027] Such as Figure 1 - Figure 8 As shown, a variable pitch large load chain according to the present invention includes two symmetrical setting of the outer chain plate 1, and the two outer chain plates 1 symmetric activity is connected to four inner chain plates 3, four inner chains. The plate 3 is divided into two groups and each group consists of two symmetrical arranged inner chain plates 3, and two of the outer side walls of the four inner chain plates 3 have two limit shafts 9, and several limit shafts are away from the corresponding One end of the inner chain plate 3 is inserted into the outer chain plate 1 of matching settings and is connected to its active, and four threaded holes 6 are opened on both outer chain plates 1, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com