Industrial intelligent motion control carrying robot

A technology of motion control and robotics, applied in cranes, transportation and packaging, load hanging components, etc., can solve the problems of inconvenient picking and placing items, unable to meet the needs of automatic handling of factory pallets, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

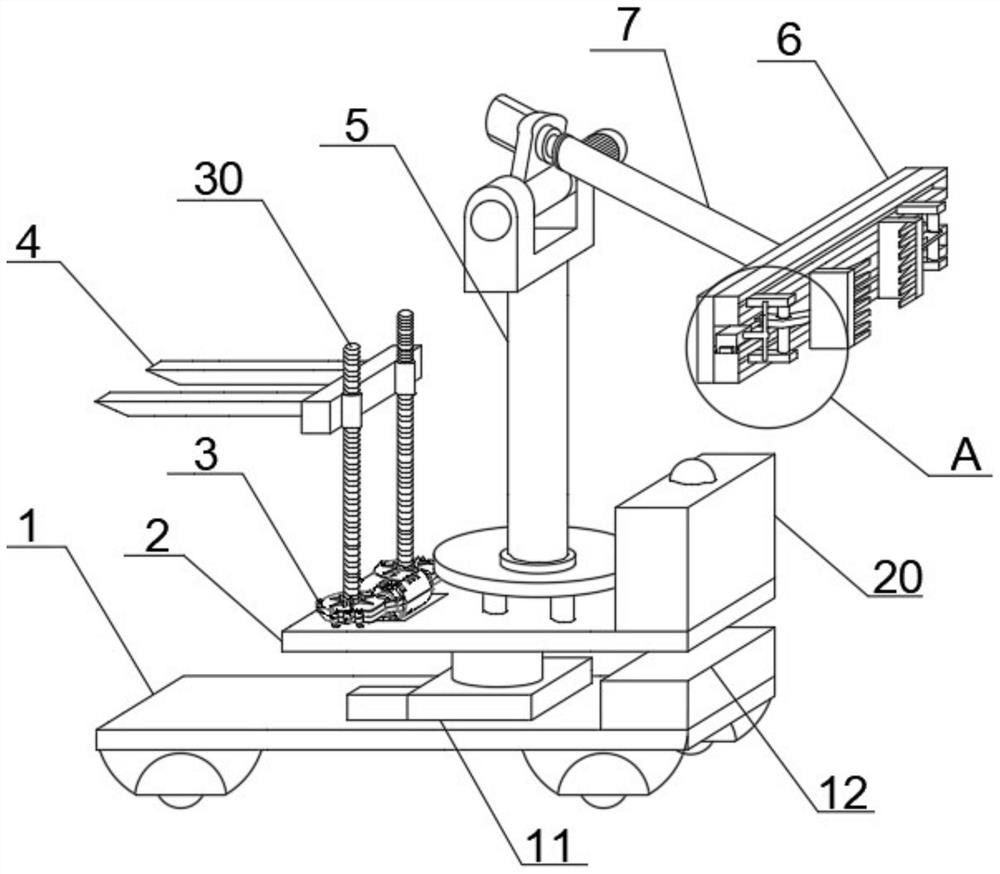

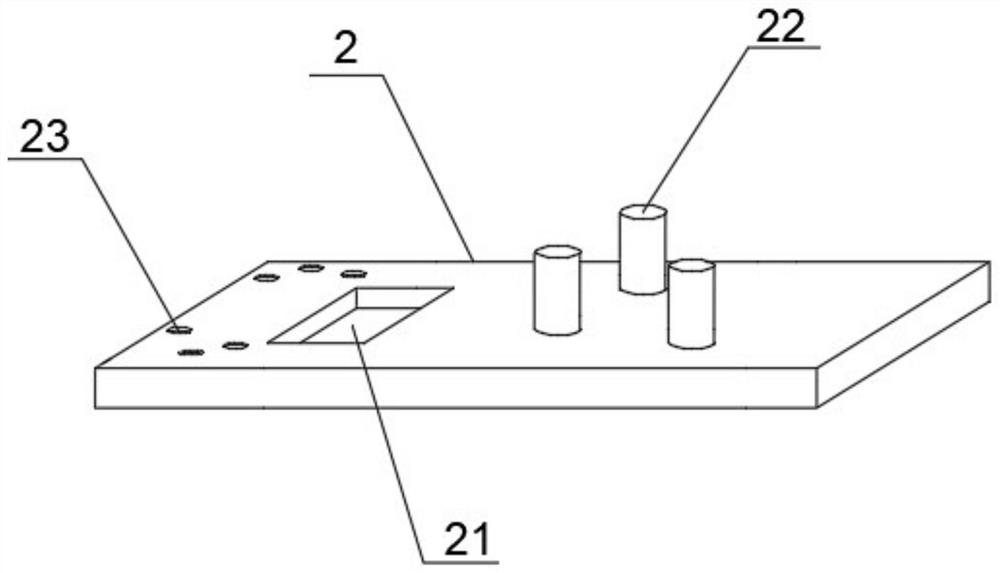

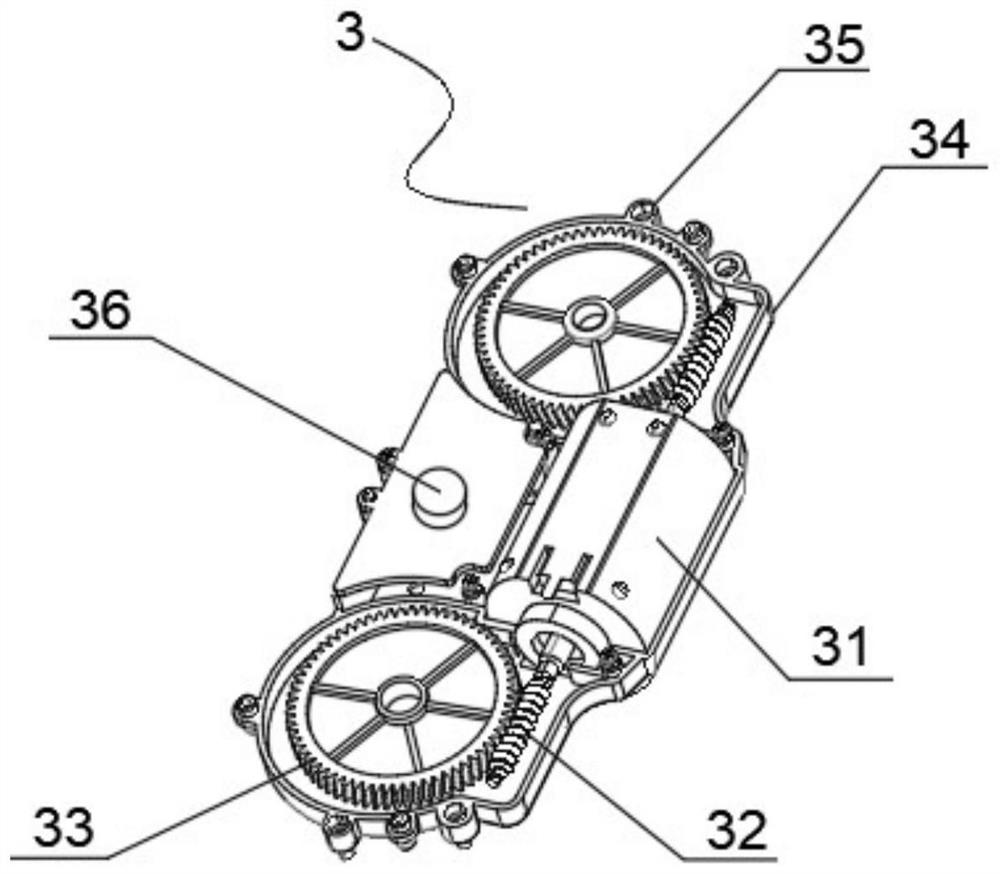

[0039] Such as figure 1 As shown, an industrialized intelligent motion control carrier robot includes a moving chassis 1, a carrier plate 2 is arranged on the moving chassis 1, an electric rotating disk 11 is arranged between the moving chassis 1 and the carrier plate 2, and the carrier The upper side of the board 2 is provided with a carrying fork body 4, and the carrying fork body 4 realizes automatic lifting through the lifting power drive structure 3, and the upper side of the carrier board 2 is provided with an electric control box 20. The control box 20 includes a control system and a sensor system. A rotatable mechanical shaft arm structure 5 is provided between the carrying fork 4 and the electric control box 20. A rotatable mechanical shaft arm structure 5 is provided on the top of the mechanical shaft arm structure 5. The telescopic mechanical arm 7 is provided with a rotatable mechanical gripper structure 6 at the top of the telescopic robotic arm 7 , and the mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com