Adjustable diamond saw blade edging machine sucker

A diamond saw blade, adjustable technology, applied in the direction of metal sawing equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of high labor intensity, low production efficiency, heavy workload, etc., to reduce the labor force of workers Strength, improved production efficiency, adjustable spacing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

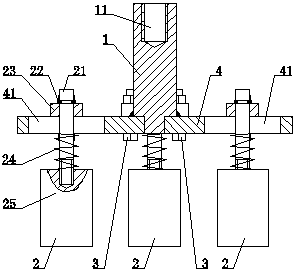

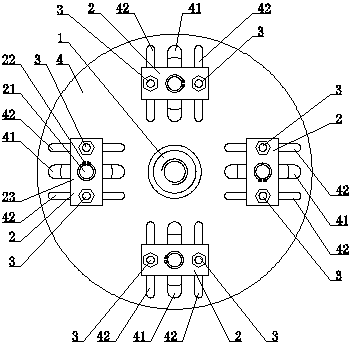

[0008] see Figure 1 to Figure 2 , the present invention comprises a connecting handle 1, a disk support 4, several elastic electromagnetic chucks 2 and several bolts 3, the top of the connecting handle 1 is provided with a threaded hole 11, and the elastic electromagnetic chuck 2 includes a guide rod 21, Collar 22, connecting plate 23, compression spring 24 and electromagnetic sucker 25, described disc support 4 is provided with four waist-shaped holes I41 uniformly distributed in the circumferential direction, and in the waist shape of each disc support 4 Both sides of the hole I41 are symmetrically provided with a waist-shaped hole II42, and the connecting handle 1 is welded to the middle part of the disc support 4, and the collar 22, the connecting plate 23, the compression spring 24 and the electromagnetic chuck 25 are arranged sequentially from the top. To be installed on the guide rod 21, the guide rod 21 is installed in the waist-shaped hole I41 of the disc support 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com