Cutting tool for busbar heat-shrinkable tube

A technology of heat-shrinkable tubes and busbars, which is applied in metal processing and other directions, can solve the problems of hidden safety hazards and low efficiency of heat-shrinkable tubes for busbars, and achieve the effect of simple and efficient cutting and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

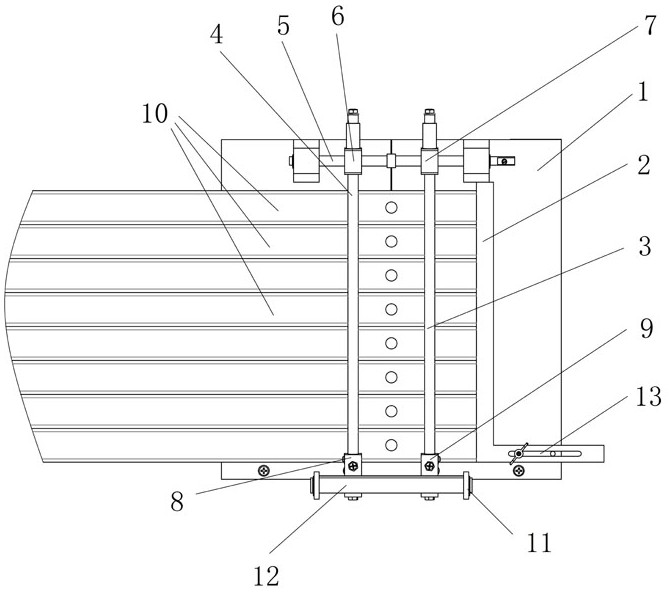

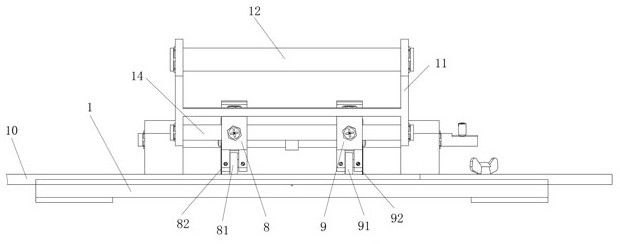

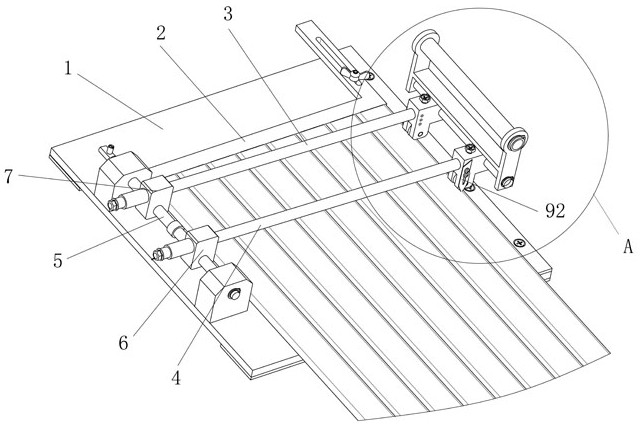

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Specific embodiments of the cutting tool for busbar heat-shrinkable tubes provided by the present invention:

[0034] like Figure 1 to Figure 4 As shown, the busbar heat-shrinkable tube cutting tool includes a base 1, which is used to lay a plurality of busbars 10 horizontally along the front and rear directions. The busbars 10 extend along the left and right directions. Copper row.

[0035] A stop ruler 2 is provided on the base 1 for positioning and cooperating with the end stop of the busbar 10 . The stop ruler 2 is an L-shaped structure including vertical and horizontal sides. The vertical side of the stop ruler 2 is matched with the right end surface of the busbar 10 for blocking and positioning. After the left and right directions are adjusted in place, the bolt passes through the long hole 13 to screw the stopper 2 onto the base 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com