Local area network remote monitoring system based on SIEMENS840D numerical control system

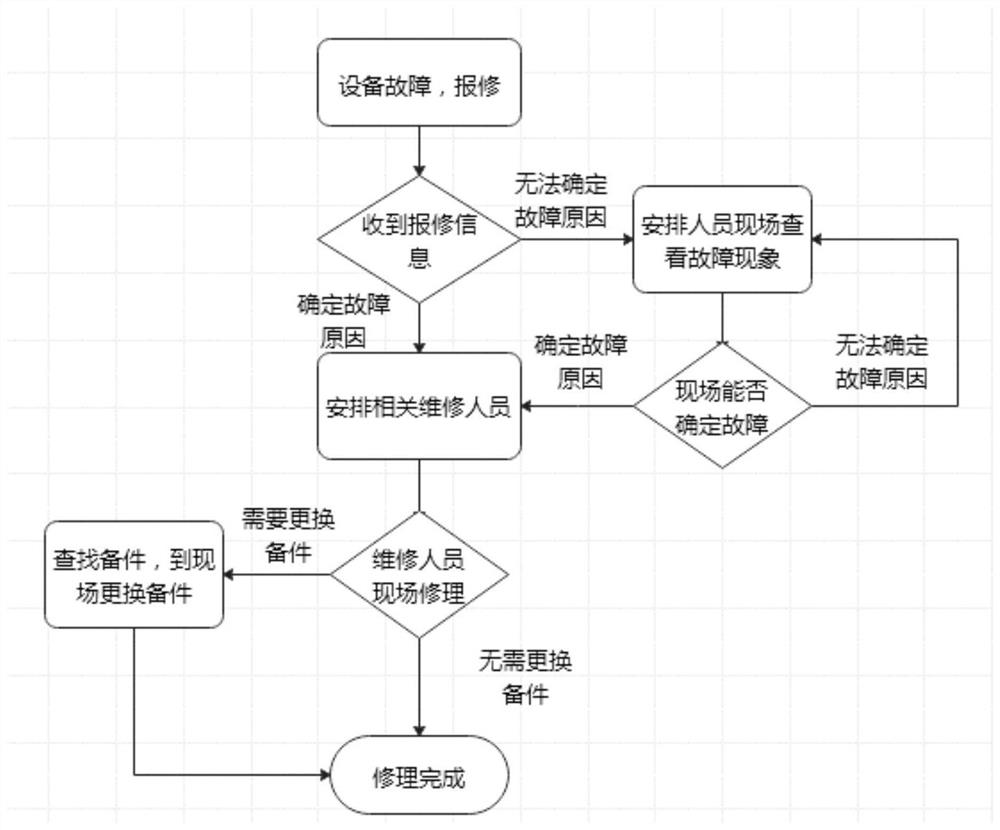

A technology of remote monitoring system and numerical control system, which is applied in the field of numerical control machine tools, can solve the problems that on-site operators cannot clearly describe the fault phenomenon, cannot correctly judge the cause of the fault, and the cost, etc., so as to shorten the repair time of the fault and improve the efficiency of fault handling , Reduce the effect of equipment downtime rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

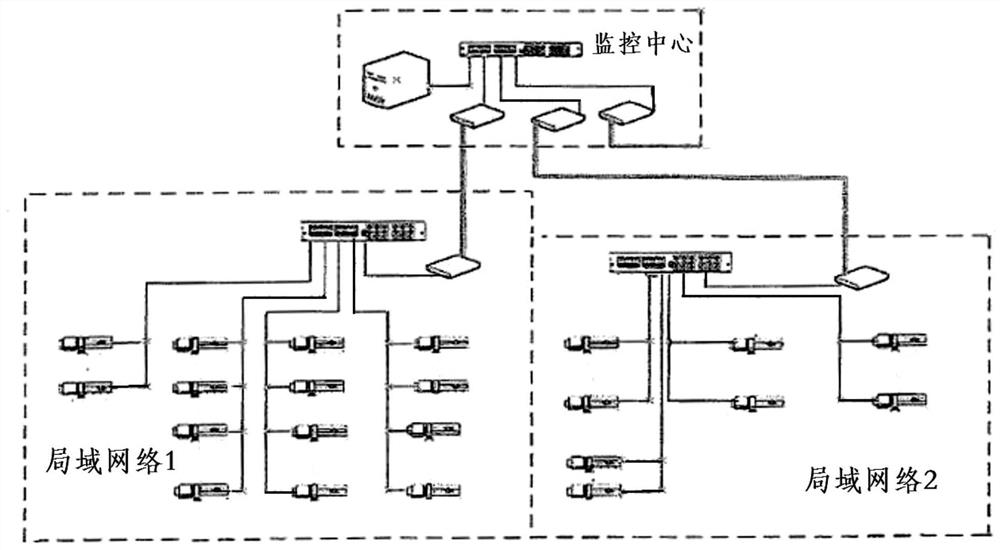

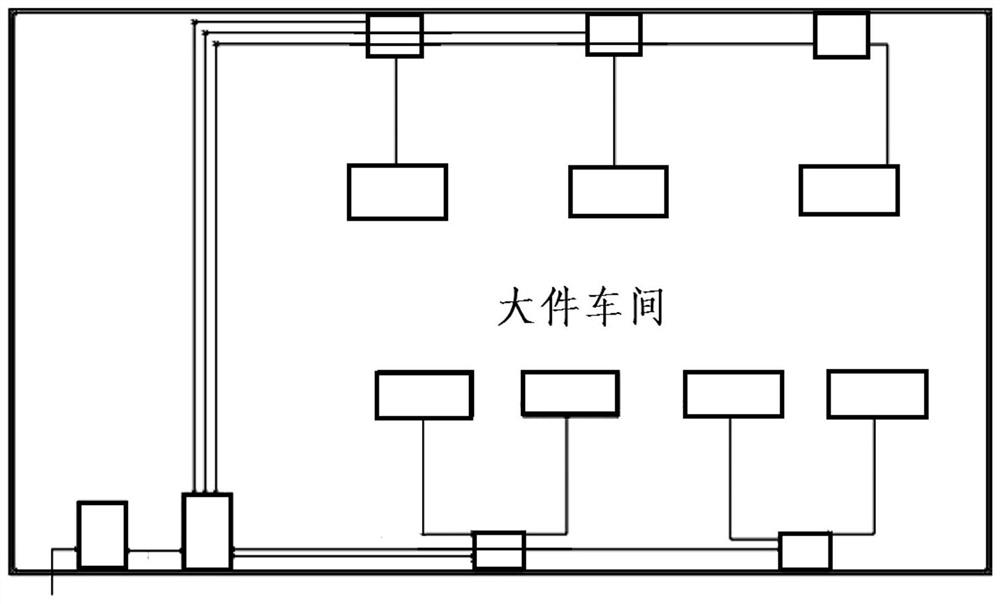

[0022] The production operation site is a large-scale workshop (local area network 1) and a medium-sized workshop (local area network 2), each of which is equipped with a number of equipment using the SIEMENS 840D numerical control system; personal office computers used by equipment maintenance personnel working in the monitoring center are placed In the scientific research building.

[0023] 1. Establish a CNC equipment LAN (LAN 1 and LAN 2) for all SIEMENS 840D CNC system equipment in the workshop (production site).

[0024] The establishment of CNC equipment LAN is mainly to realize digital control of field equipment, remote transmission and monitoring of data, and real-time monitoring of equipment status, so as to improve production efficiency, management efficiency and maintenance efficiency. The invention mainly realizes the real-time monitoring of the equipment state.

[0025] The CNC equipment local area network is a network system based on Ethernet technology. The ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com