Cell contact device and battery system

A contact device and electrical contact technology, applied in the direction of batteries, battery pack components, circuits, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

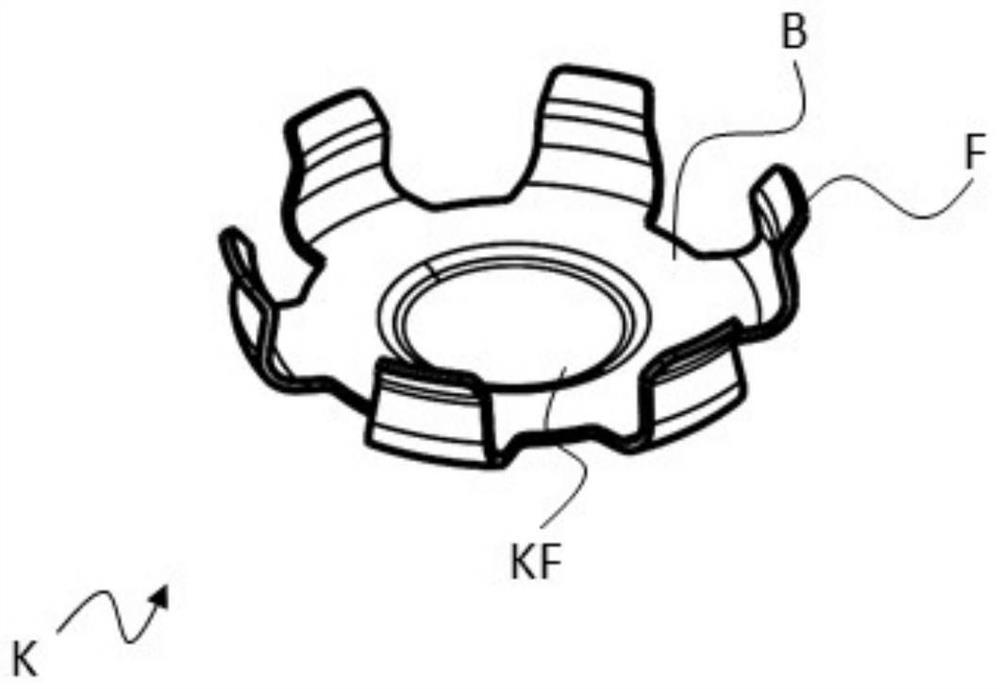

[0053] figure 1 A known contact crown K is shown. The contact crown K has a circular base B, on the periphery of which six contact lugs F are evenly distributed. In the middle of the base B, a downwardly offset contact surface KF is arranged.

[0054] The illustrated contact crown K can be produced, for example, as a stamped and bent part. Electrical contacting to the positive pole of the battery cell can be achieved by connecting the contact surface KF to the positive pole. The negative pole of the battery cell can be contacted by pushing the contact lug F on the housing of the battery cell.

[0055] If several negative poles are to be connected in parallel, a corresponding number of contact crowns K with contact surfaces KF must be arranged on the electrically conductive carrier.

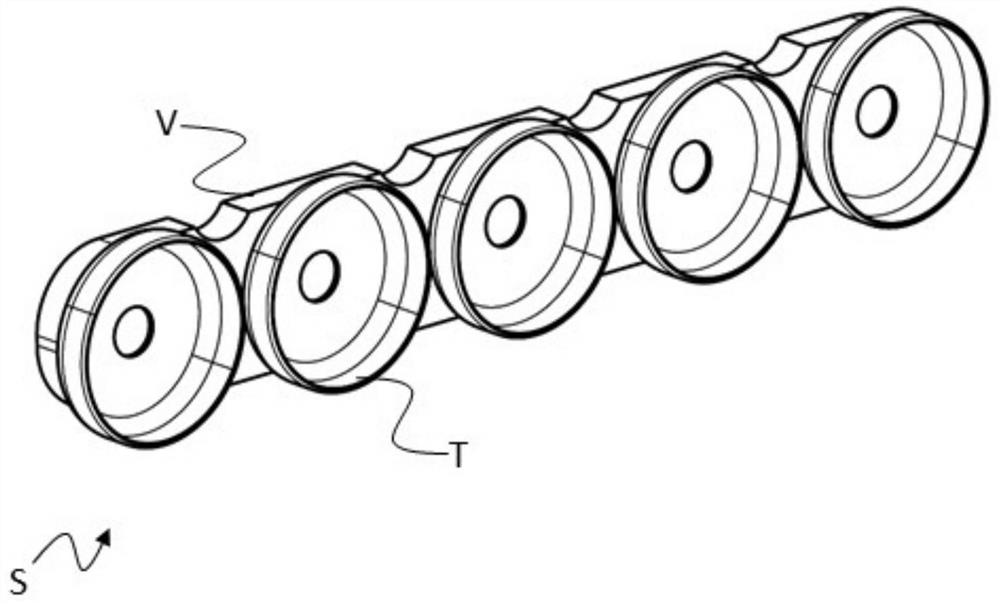

[0056] figure 2 shows a diagram of a known current rail S that is required to operate with a figure 1 The contact crown K is an electrical contact in parallel with the positive pole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com