Feeding and discharging device for 3C electronic product production

A technology for electronic products and horizontal plates, which is applied in the field of loading and unloading devices for 3C electronic product production, which can solve the problems of high fixture manufacturing and maintenance costs, increased fixture failure rate, and low automation, and achieves simple structure and reduced use and maintenance costs. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

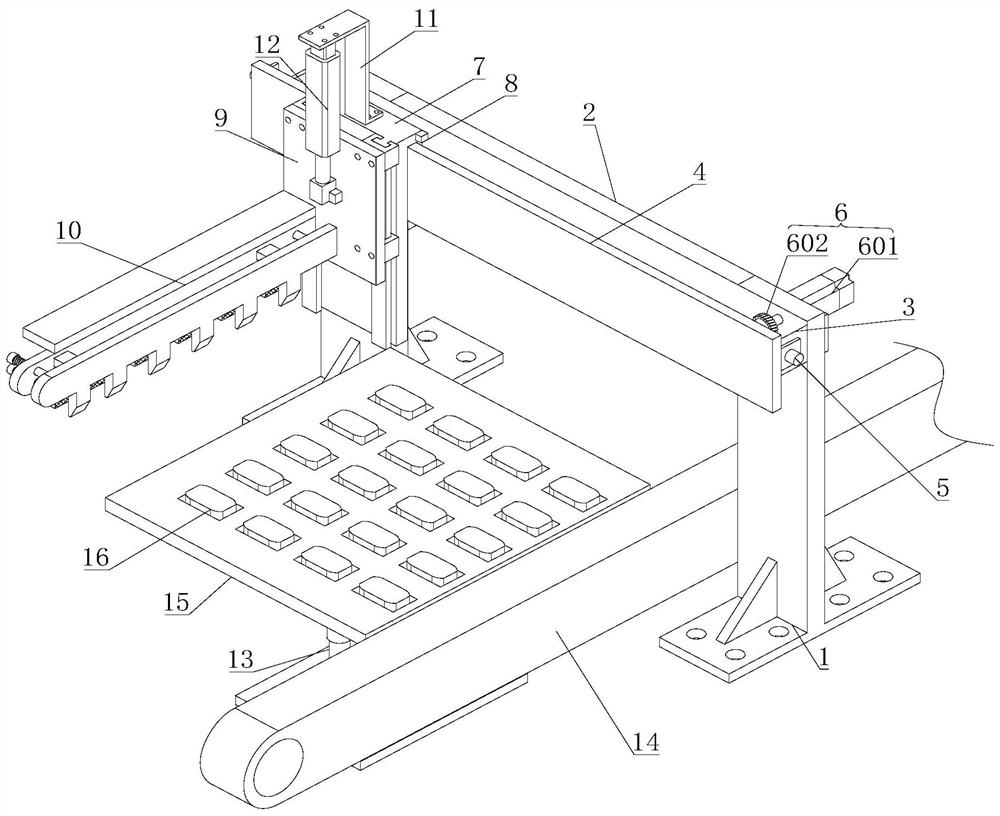

[0025] Such as figure 1 shown;

[0026] figure 1 It is a structural schematic diagram of the present invention.

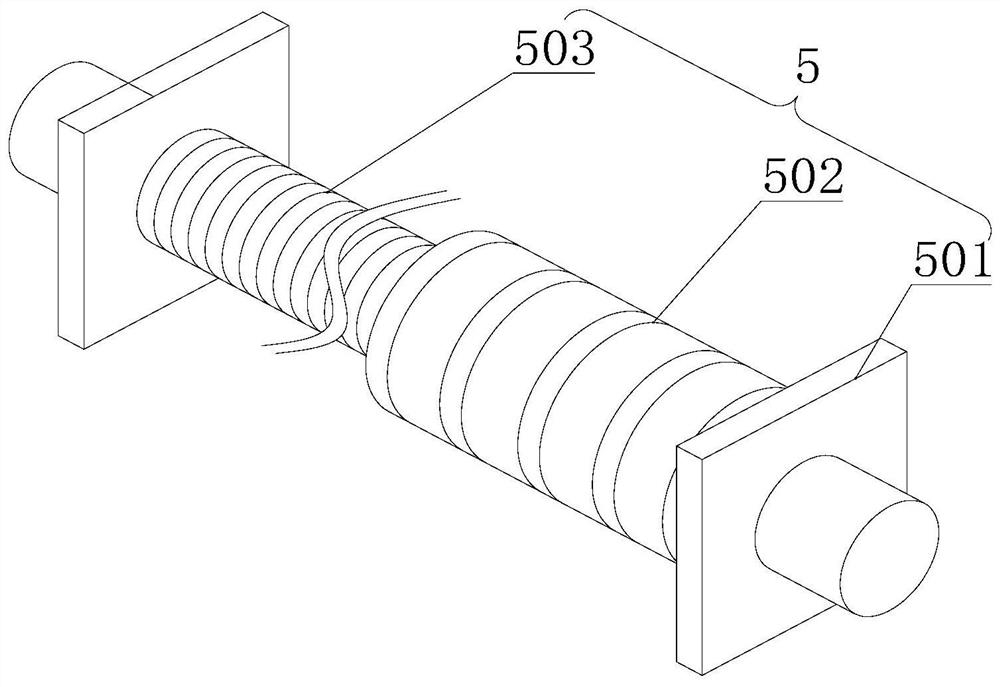

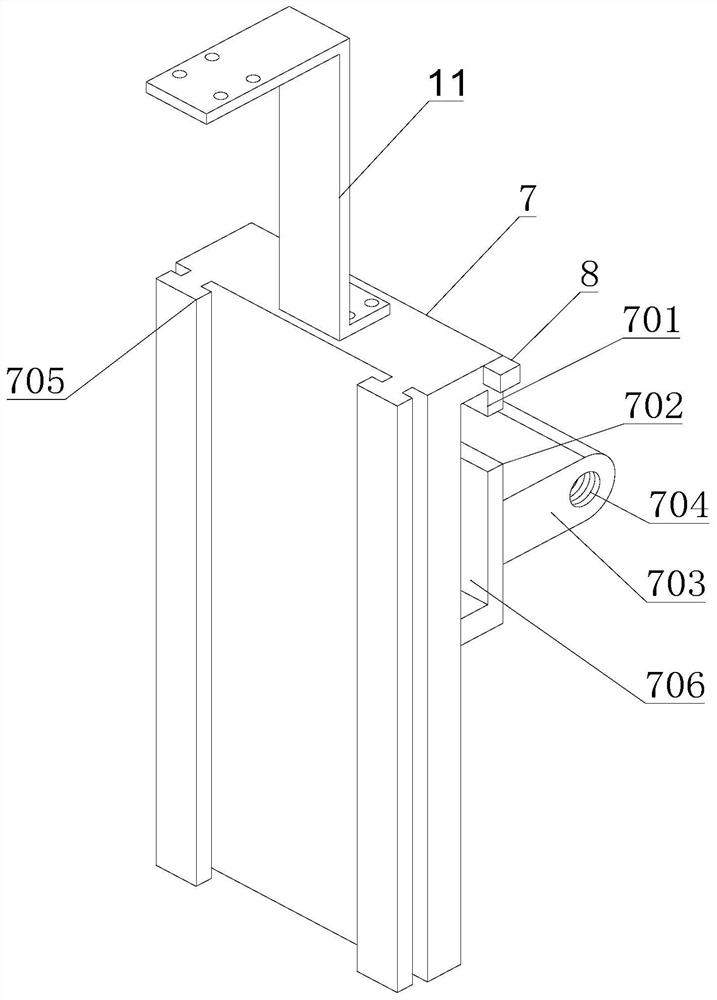

[0027] A loading and unloading device for 3C electronic product production, comprising two symmetrical fixed seats 1, characterized in that: the top ends of the two fixed seats 1 are fixedly connected by a horizontal plate 2, and one side of the horizontal plate 2 is symmetrically provided with End plate 3, the end of the end plate 3 away from the horizontal plate 2 is provided with a support plate 4, a worm assembly 5 is arranged between the two end plates 3, one side of the horizontal plate 2 is located on the fixed The top of the seat 1 is provided with a servo drive mechanism 6, and the servo drive mechanism 6 is matched with the worm assembly 5, and the side of the support plate 4 away from the horizontal plate 2 is provided with a clamping plate 7, the clamping plate One side of 7 is provided with a displacement sensor 8, and the clamping plate 7 and the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap