Turnover device for precision shaft production

A precision shaft and turnover box technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems that affect corporate image, missed inspections, and unqualified products leave the factory, and achieve the effect of convenient turnover transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

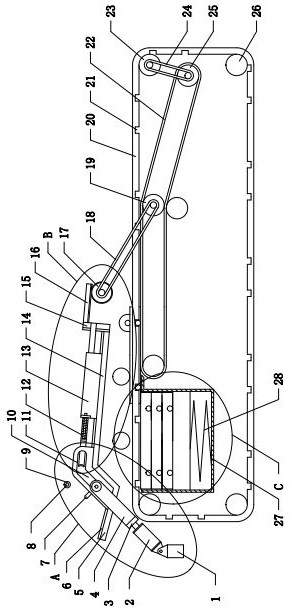

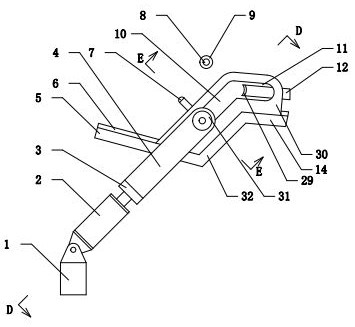

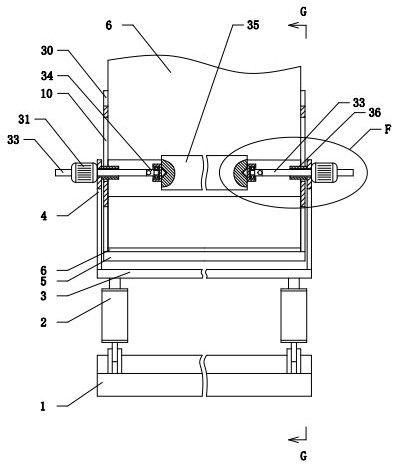

[0033] Example: as attached Figures 1 to 7 As shown, a turnover device for precision shaft production includes a frame, and the frame is provided with a first pallet 5 and a second pallet 32 arranged obliquely. The lower end of the first pallet 5 is connected to the second pallet 32. The lower ends of the supporting plates 32 are connected, and the first supporting plate 5 and the second supporting plate 32 form a V-shaped structure for placing the precision shaft 35 . The upper end of the second supporting plate 32 is provided with a sloping plate 14, and the first supporting plate 5, the second supporting plate 32 and the sloping plate 14 are all provided with a sponge pad 6 to prevent the precision shaft 35 from contacting the first supporting plate. Plate 5, second supporting plate 32 or slope plate 14 collide, causing precision shaft 35 to be damaged. Below the lower end of the ramp 14 is provided a turnover box 51 capable of holding the precision shaft 35. When the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com