A method for calibrating and verifying the accuracy of weight loss scales with substitutes

A substitute, a technology of reducing scales, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of low precision of weighting scales, reduced precision of weighting scales, and small quantity of reference materials, etc., so as to improve operation convenience and save money. The effect of manpower and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the embodiments.

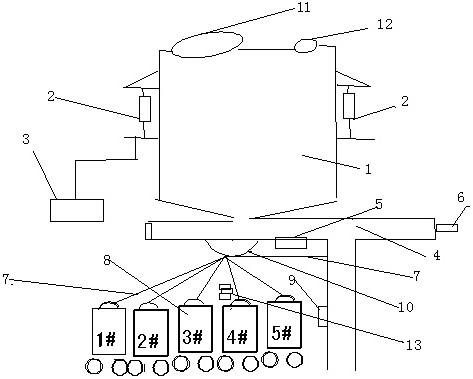

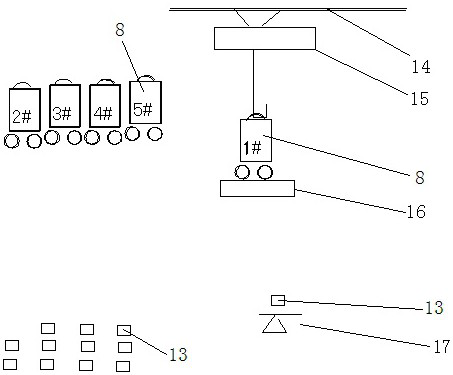

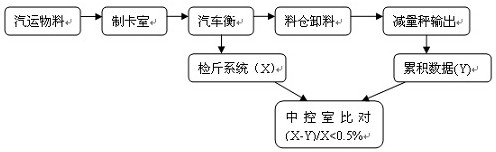

[0034] The invention discloses a method and method for calibrating a weight loss scale with a mobile substitute, see Figure 1-Figure 3 , including the following steps:

[0035] Step A: Selection of substitutes, select the substitutes for calibration according to the site conditions and the range of the weighing scale;

[0036] Step B: Clean the appearance of the selected substitute, determine the number, paste the logo, and record the file operation;

[0037] Step C: carry out numerical traceability to the selected substitute;

[0038] Step D: perform static calibration on the weight loss scale using the value traceable substitute;

[0039] Step E: Single-bucket material calibration reduction scale;

[0040] Step F: Physical verification of the precision of the weight reduction scale during the production process.

[0041] In step A, the substitutes include high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com