Testing device and testing method for permeability of carbon fiber cloth in laying direction

A carbon fiber cloth and testing device technology, applied in the field of energy storage, can solve the problems of too many parts and complex assembly of the testing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

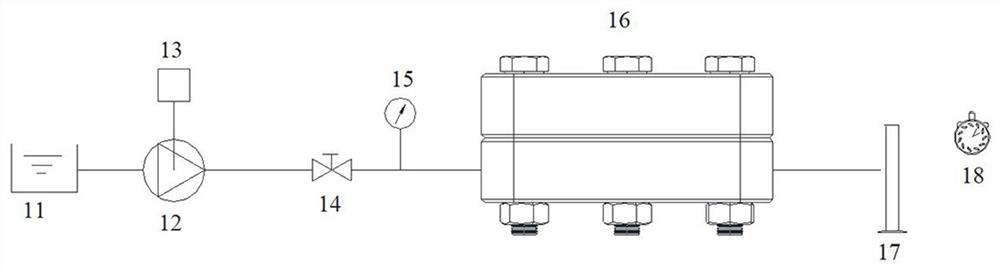

[0048]Such asfigure 1 As shown, a test device for the permeability of carbon fiber cloth in the direction of the ply includes a water tank 11, a frequency converter 13, a pump 12, a valve 14, a pressure gauge 15, a carbon fiber cloth fixture 16, a measuring cylinder and a timer 8.

[0049]The carbon fiber cloth clamp 16 has a water inlet and an outlet. The water tank 11 is connected to the water inlet through a pipeline. A pump 12 and a pressure gauge 15 are provided on the pipeline. The water outlet of the carbon fiber cloth clamp is connected to the water outlet. Mentioned measuring cylinder 17.

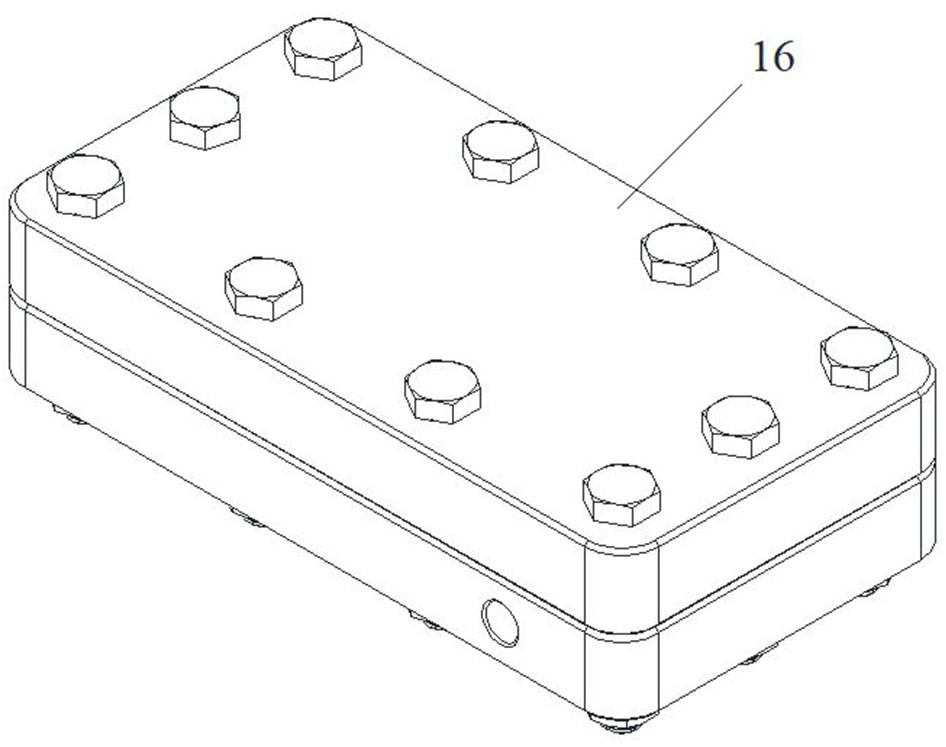

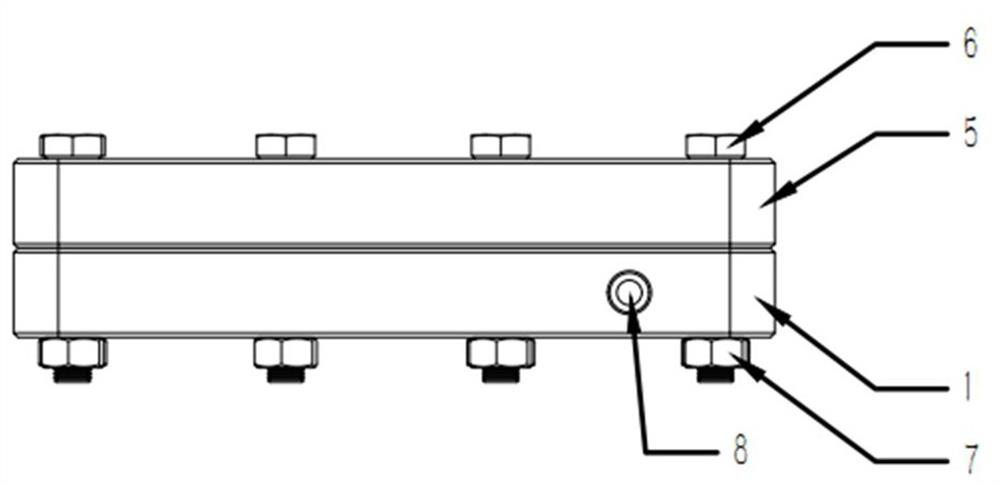

[0050]SeeFigure 2A ,Figure 2B ,image 3 The carbon fiber cloth fixture includes a cube-shaped upper fixture 5 and a lower fixture 1. The upper fixture 1 and the lower fixture 5 are fixed by bolts 6 and nuts 7; between the upper fixture 5 and the lower fixture 1 is the position for laying carbon fiber cloth, Two liquid inlet / outlet threaded holes 8 of the same size are opened on two opposite sid...

Embodiment 2

[0057]Using the device of Example 1, a method for testing the permeability of carbon fiber cloth in the direction of the ply, including operations:

[0058]Laying carbon fiber cloth and rectangular silica gel pad in the carbon fiber cloth fixture, fixing the upper and lower fixtures with bolts, and connecting pipelines;

[0059]Use a pump to send the fluid in the water tank into the carbon fiber cloth fixture, the fluid flows in from the inlet and out from the outlet, and the outflow measuring cylinder measures the volume, and the timing tool measures the time it takes to reach a certain volume in the measuring cylinder;

[0060]Use a pressure gauge to measure the fluid pressure at the inlet of the carbon fiber cloth fixture,

[0061]The inverter achieves the purpose of adjusting the water supply pressure of the fixture by controlling the frequency of the water pump, and the valve controls the on and off of the entire test flow path.

[0062]Turn on the water pump, adjust the frequency of the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com