Round biscuit making machine

A biscuit and circular technology, applied in the field of circular biscuit making machines, can solve the problems of waste, inability to accurately pour materials, and poor biscuit production effect, and achieve the effect of high safety performance and improved production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

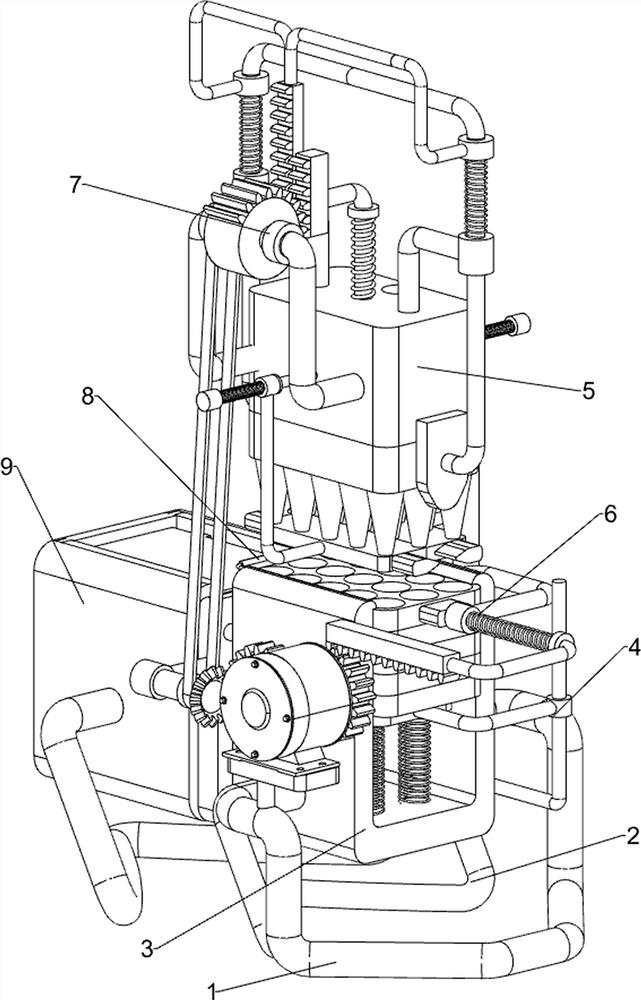

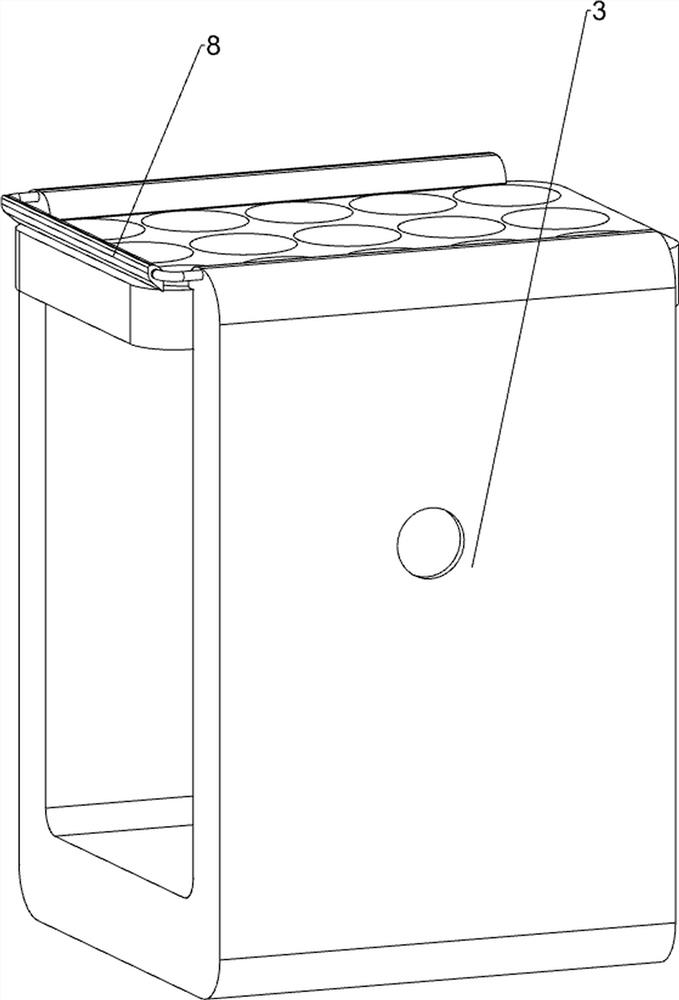

[0072] A round biscuit making machine such as figure 1 As shown, it includes a first support rod 1, a second support rod 2, a feeding frame 3, a charging mechanism 4 and a feeding mechanism 5, and a feeding frame 3 is provided on the first supporting rod 1 and the second supporting rod 2 , the discharging frame 3 is provided with a loading mechanism 4, and the discharging frame 3 is provided with a discharging mechanism 5.

[0073] When it is necessary to make round biscuits, people first put a certain number of round cookie molds into the discharging frame 3 in turn, and then make the charging mechanism 4 move downward, and then people manually press down the feeding mechanism 5, so that the feeding mechanism 5 is blocked, at this time pour the prepared material into the unloading mechanism 5, then release the unloading mechanism 5, the unloading mechanism 5 moves up and resets without blocking the material, so that the material flows to the circle below. In the biscuit mold...

Embodiment 2

[0075] On the basis of Example 1, as figure 2 , image 3 and Figure 4 As shown, the charging mechanism 4 includes a positioning rod 41, a sliding sleeve plate 42 and a first spring 43. A positioning rod 41 is provided at the lower part of the rear side of the discharging frame 3, and a sliding sleeve plate 42 is slidably provided on the positioning rod 41. A first spring 43 is evenly connected between the bottom of the sleeve plate 42 and the inner lower wall of the discharging frame 3 .

[0076] When installing the circular biscuit mold, each time a circular biscuit mold is placed, the sliding sleeve plate 42 is forced to move down a short distance, and the first spring 43 is compressed at this time, and the circular biscuit is removed after the material is loaded. mold, so that the force on the sliding sleeve plate 42 is reduced, the reset of the first spring 43 drives the sliding sleeve plate 42 to move up a short distance, until all the circular biscuit molds are fille...

Embodiment 3

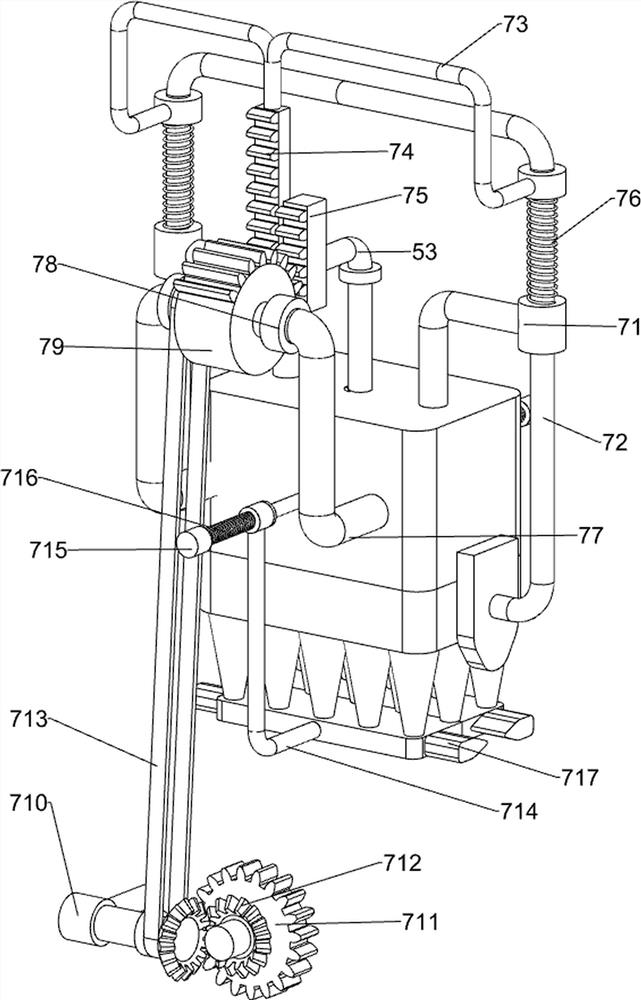

[0080] On the basis of Example 2, as figure 1 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a discharging mechanism 6, an automatic intermittent discharging mechanism 7, a scraper 8 and a receiving mechanism 9. The discharging frame 3 and the first support rod 1 are provided with a discharging mechanism 6, and the discharging frame 3 An automatic intermittent discharging mechanism 7 is arranged on the discharging frame 52 , a scraper 8 is arranged on the upper left side of the discharging frame 3 , and a receiving mechanism 9 is placed on the left side of the discharging frame 3 .

[0081] The discharging mechanism 6 can realize automatic discharging, and the automatic intermittent discharging mechanism 7 can realize automatic discharging. When making round biscuits, people pour the material into the discharging frame 52, and the material flows to the lower part of the discharging frame 52. However, it is blocked by the automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com