Base fixing device for mining equipment

A technology for mining equipment and fixtures, applied in mechanical equipment, supporting machines, vibration suppression adjustment, etc., can solve the problems of small buffering force of the shock absorbing structure, affecting the stability of the equipment, less shock absorbing structure, etc., and achieve stable fixing and clamping. , easy to promote, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

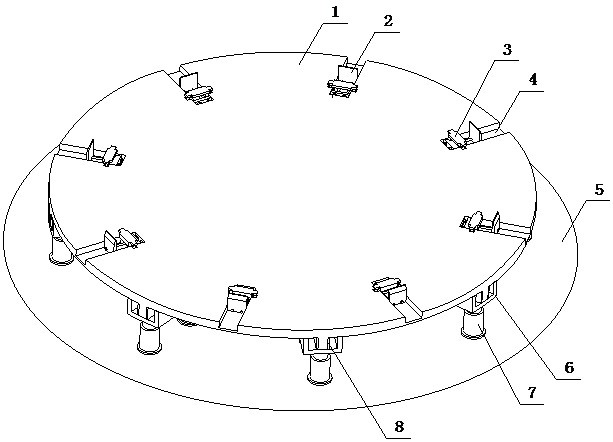

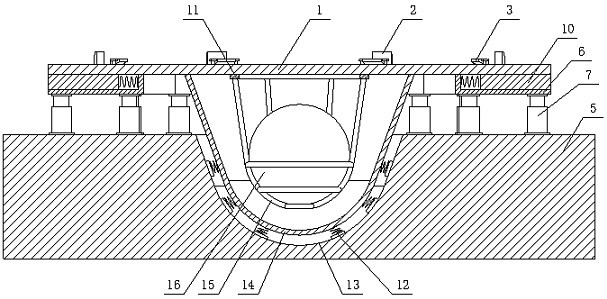

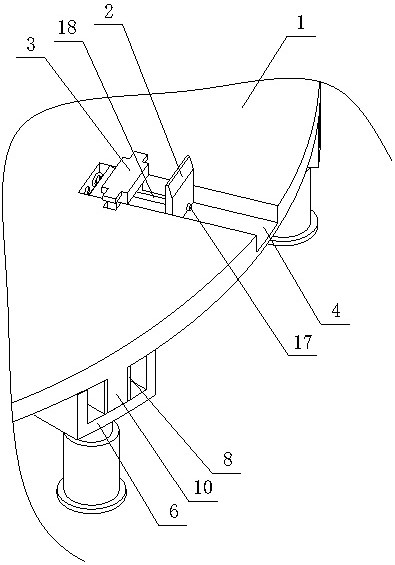

[0020] A base fixing device for mining equipment of the present invention is realized in the following way: a base fixing device for mining equipment of the present invention consists of a fixing seat (1), a clamping plate (2), a pressing block (3), a chute (4), Guide sleeve (6), hydraulic cylinder (7), support plate (8), damping spring (9), fixed slide bar (10), fixed ring (11), mounting seat (12), protective shell (14), Steel rope (15), damping ball (16), adjusting screw (17), connecting rod (18), guide rod (19) and wedge-shaped slider (20), the protective shell (14) is placed on the fixed seat (1) At the bottom, the fixed ring (11) is placed in the center of the fixed seat (1), and is located in the protective shell (14), and a plurality of steel ropes (15) are placed on the fixed ring (11), and a plurality of the steel ropes ( 15) Cooperate to form a steel rope (15) net, the damping ball (16) is placed in the steel rope (15) net, and a plurality of support springs are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com