High-safety gas storage device

A gas storage and high-safety technology, which is applied in the direction of gas processing/storage, gas/liquid distribution and storage, installation device of container structure, etc. cost, performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

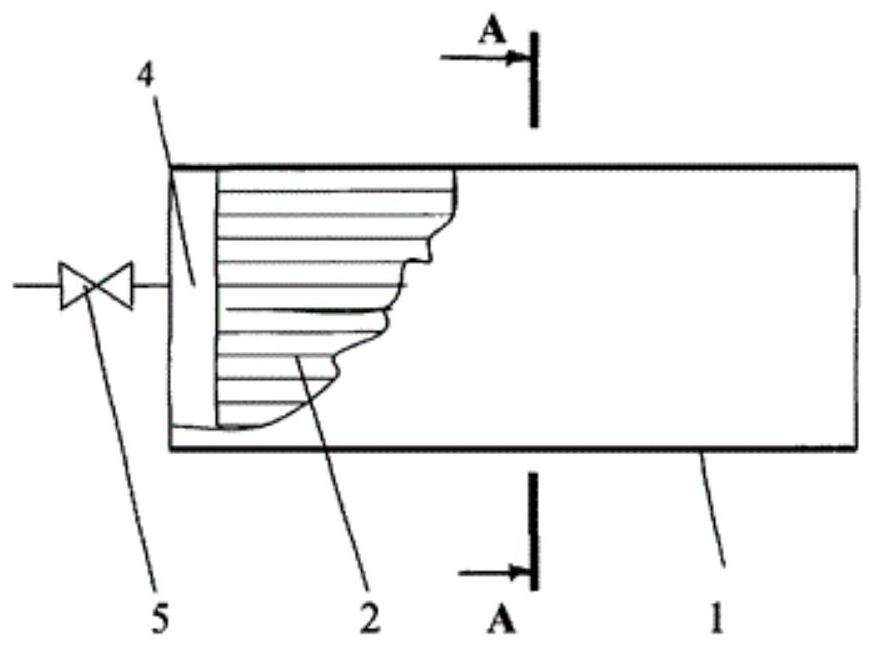

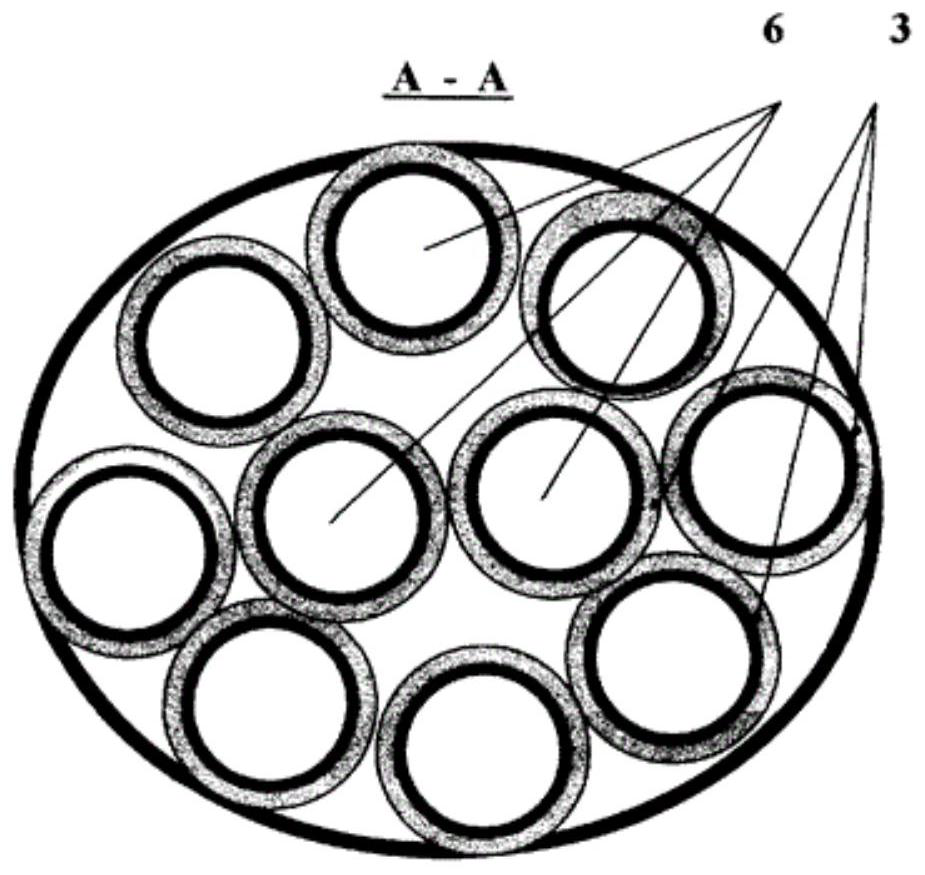

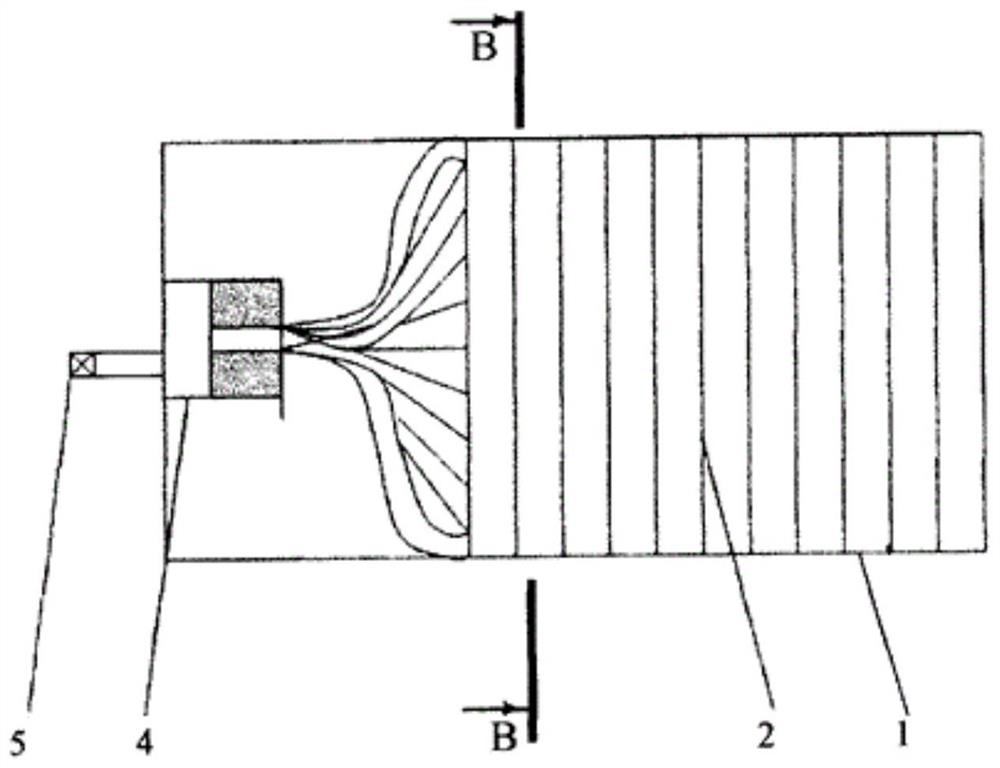

Method used

Image

Examples

Embodiment 1

[0031] Load a bundle of 400mm long and 1mm in diameter with 110atm air pressure, which contains 3957 glass capillaries (without plastic material layer) with a diameter of 14 microns and a wall thickness of 0.8 microns. After keeping for 5 minutes, open a valve connected to the atmosphere, and the Hydrodynamic impact, capillary bundles rupture, forming fine dust.

Embodiment 2

[0033] A bundle of glass capillaries (with a layer of plastic material - wood alloy, layer thickness 20 μm) is 400 mm long and 1 mm in diameter, containing 3957 capillaries with a diameter of 14 μm and a wall thickness of 0.8 μm. After being filled with air pressure of 110 atmospheres for 5 minutes, a valve connected to the atmosphere was opened, and the beam did not collapse.

Embodiment 3

[0035] The capillary made of quartz (without plastic material layer) is 600 mm long, 100 microns in diameter, and has a wall thickness of 12.5 microns. The air pressure in the capillary is 1500atm, the special equipment in the center of the capillary is destroyed, and the capillary completely collapses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com