TPEE backing plate material for rail transit and preparation process of TPEE backing plate material

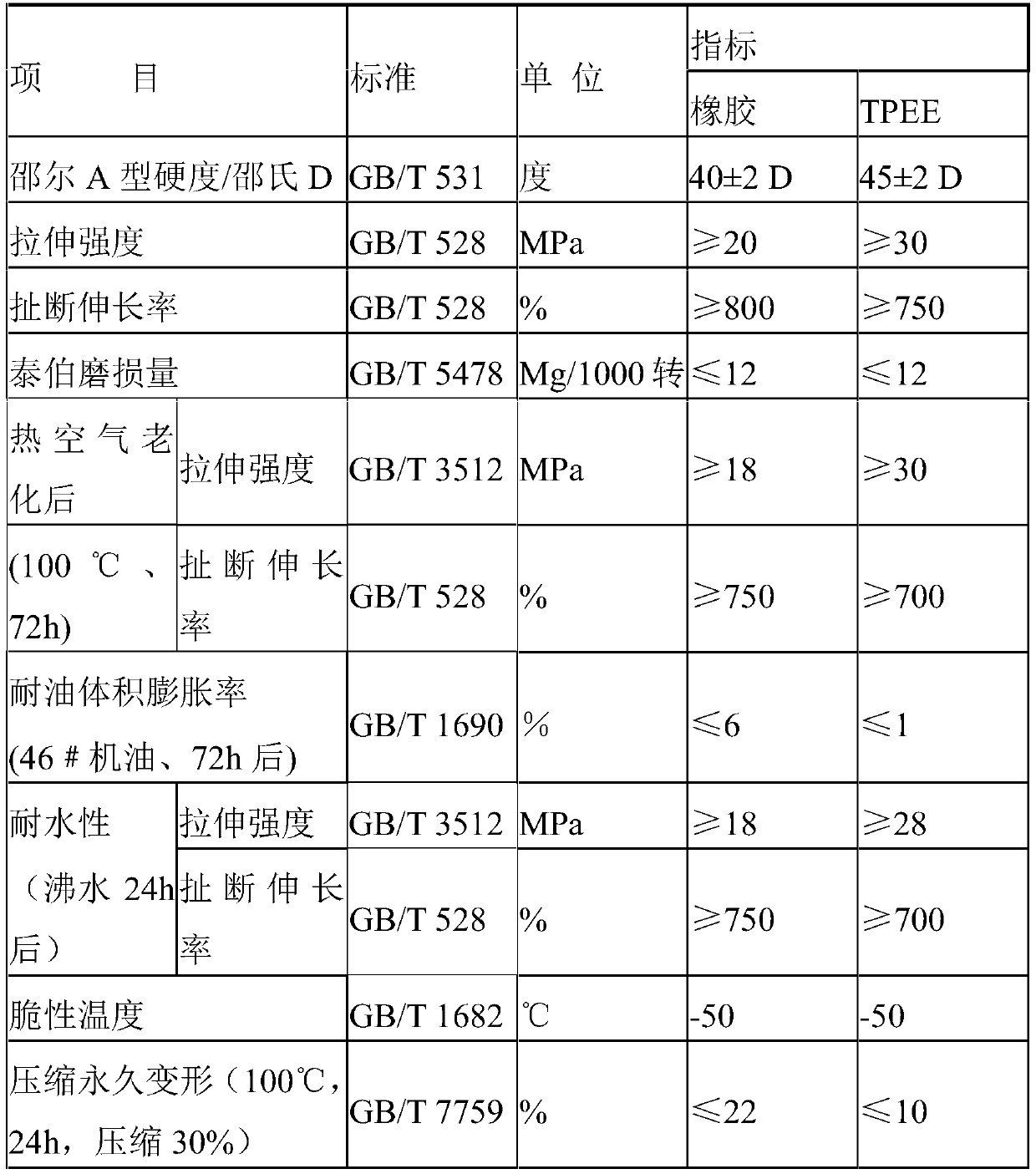

A technology for rail transit and backing plate, applied in the field of TPEE backing plate material for rail transit and its preparation technology, can solve the problems of easy change and decrease of static stiffness and dynamic stiffness, short service life of rubber material, large elastic deformation of rubber backing plate, etc. , to achieve the effect of excellent chemical resistance, stable structure and small elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of technology of rail transit TPEE pad material, comprises the following steps:

[0035] (1) Preparation of modified silica: add silica to ethanol solution, ultrasonically disperse for 3-5 minutes, add KH570 coupling agent to oxalate ethanol solution with pH 3-4, couple silica ethanol solution with KH570 Mix the oxalic acid-ethanol solution of the joint agent according to the volume ratio of 1:1; oscillate and mix at 80-90°C for 3 hours, then centrifuge, wash with 50% ethanol solution for 2-3 times, and dry the centrifuged sediment;

[0036]Dry TPEE at 60°C for 48h, mix the dried TPEE and modified silica on a torque rheometer and mix evenly, the mixing temperature is 200°C, and the mixing time is 2min to obtain TPEE / SiO 2 composite materials;

[0037] (2) Preparation of UV-absorbing masterbatch: Weigh carbon black masterbatch and EVA wax and mix in a mixer. The mixing temperature is 170-180°C and the mixing time is 10 minutes. After the mixed mixture is crushed,...

Embodiment 2

[0042] A kind of technology of rail transit TPEE pad material, comprises the following steps:

[0043] (1) Preparation of modified silica: add silica to ethanol solution, ultrasonically disperse for 3-5 minutes, add KH570 coupling agent to oxalate ethanol solution with pH 3-4, couple silica ethanol solution with KH570 Mix the oxalic acid-ethanol solution of the joint agent according to the volume ratio of 1:1; oscillate and mix at 80-90°C for 3 hours, then centrifuge, wash with 50% ethanol solution for 2-3 times, and dry the centrifuged sediment;

[0044] Dry TPEE at 60°C for 48 hours, mix the dried TPEE and modified silica on a torque rheometer and mix evenly, the mixing temperature is 200°C, and the mixing time is 2min to obtain TPEE / SiO2 composite material;

[0045] (2) Preparation of UV-absorbing masterbatch: take carbon black masterbatch and EVA wax and mix in a mixer, the mixing temperature is 175°C, and the mixing time is 6min, and the mixed mixture is crushed and granu...

Embodiment 3

[0050] A kind of technology of rail transit TPEE pad material, comprises the following steps:

[0051] (1) Preparation of modified silica: add silica to ethanol solution, ultrasonically disperse for 3-5 minutes, add KH570 coupling agent to oxalate ethanol solution with pH 3-4, couple silica ethanol solution with KH570 Mix the oxalic acid-ethanol solution of the joint agent according to the volume ratio of 1:1; oscillate and mix at 80-90°C for 3 hours, then centrifuge, wash with 50% ethanol solution for 2-3 times, and dry the centrifuged sediment;

[0052] Dry TPEE at 60°C for 48 hours, mix the dried TPEE and modified silica on a torque rheometer and mix evenly, the mixing temperature is 200°C, and the mixing time is 2min to obtain TPEE / SiO2 composite material;

[0053] (2) Preparation of UV-absorbing masterbatch: take carbon black masterbatch and EVA wax and mix in a mixer, the mixing temperature is 175°C, and the mixing time is 6min, and the mixed mixture is crushed and granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com