Heat dissipation index sensor

A sensor and sensor body technology, applied in the sensor field, can solve the problems of temperature measurement deviation, inability to accurately measure wire data, etc., and achieve the effects of small temperature data error, accurate heat dissipation index, and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

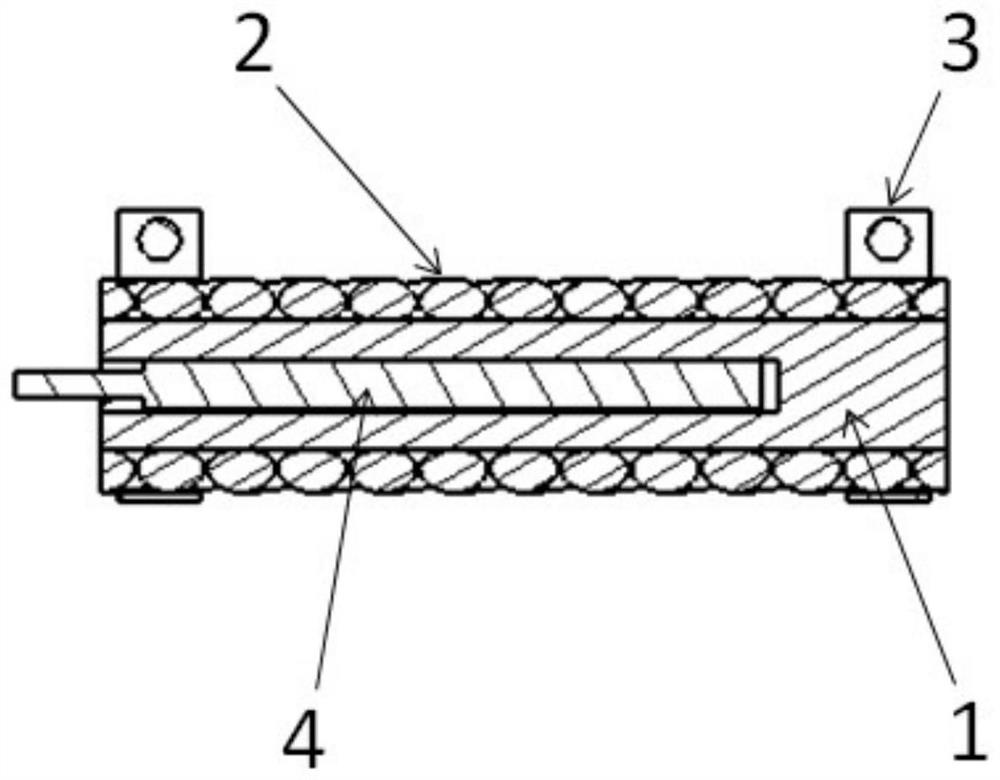

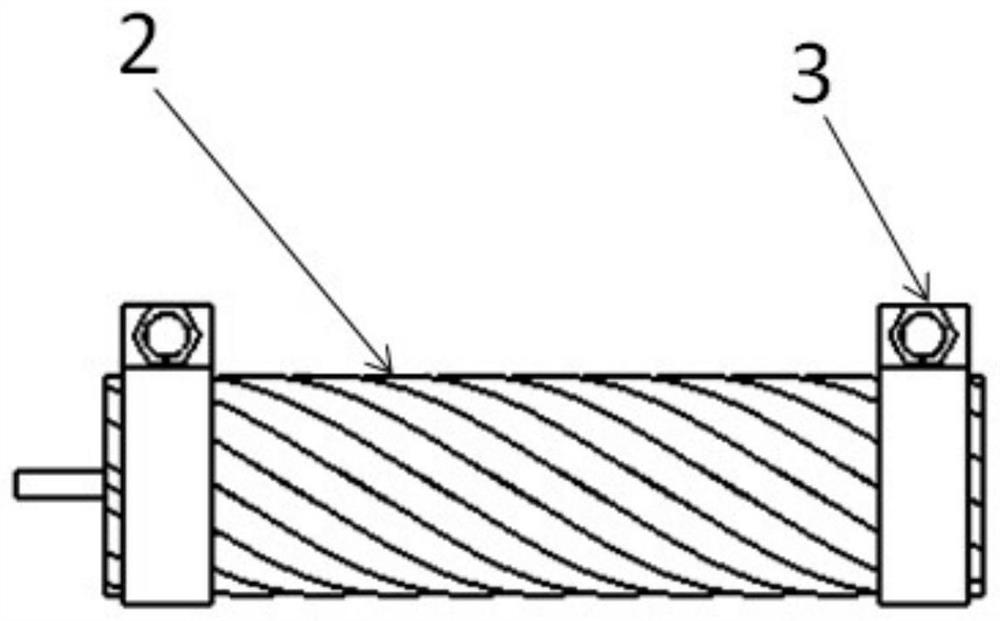

[0026] The above is the first embodiment of a heat dissipation index sensor provided by the embodiment of the present application, and the following is the second embodiment of a heat dissipation index sensor provided by the embodiment of the present application. For details, please refer to figure 1 and figure 2 .

[0027] The heat dissipation index sensor in this embodiment includes: a sensor body, the sensor body includes a cylindrical steel core 1 and a layer of aluminum twisted wire 2 wound on the outer surface of the cylindrical steel core 1, and a heating rod 4 is embedded in the cylindrical steel core 1 , The heating rod 4 has a built-in temperature sensor. That is, the sensor is divided into inner and outer layers, the inner layer is a cylindrical steel core 1, and the cylindrical steel core 1 is embedded with a heating rod 4 with a temperature measurement function of appropriate size; Skeined wire 2, the winding method of aluminum skeined wire 2 is as follows fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com