Logistics distribution method based on automated guided vehicle

An automatic guided vehicle and logistics distribution technology, applied in the direction of motor vehicles, collaborative devices, instruments, etc., can solve the problems of difficulty in controlling the timeliness and progress of distribution, affecting the circulation of waybill, and low distribution efficiency, so as to improve the speed of waybill circulation. and the overall distribution efficiency, optimized distribution methods, and the effect of not easy distribution blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

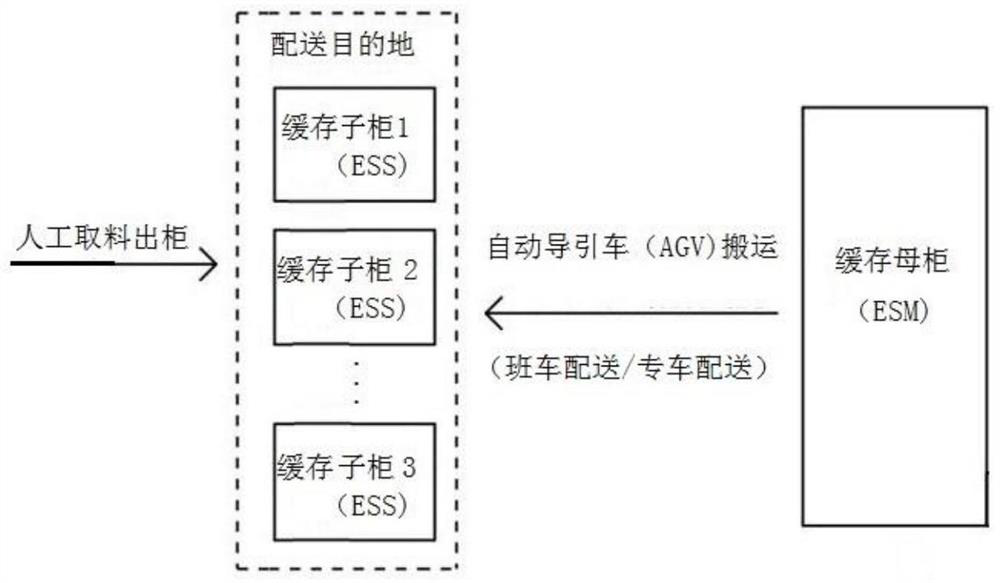

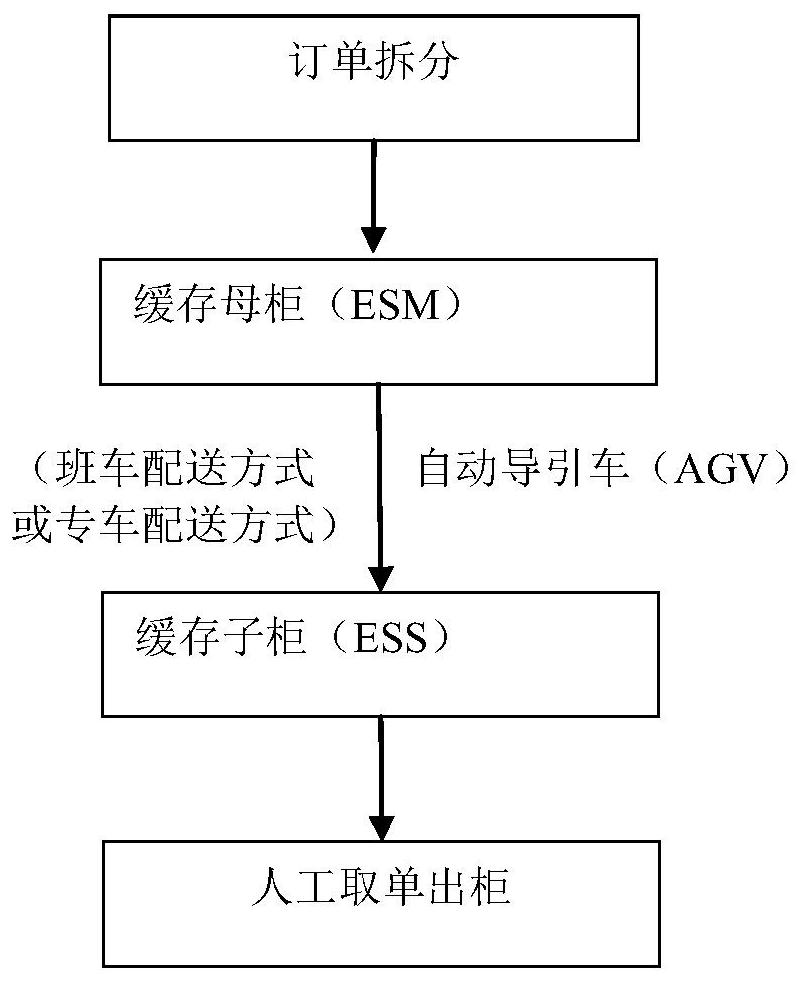

[0027] like Figure 1-Figure 2 As shown, this embodiment discloses a logistics distribution method based on automatic guided vehicles, the method includes the following steps:

[0028] 1) Split the multiple materials in the order, place the split materials in the corresponding positions of the buffer master cabinet ((ESM)) and generate a delivery task, and insert the delivery task into the current delivery queue;

[0029] 2) Call the automatic guided vehicle (AGV) to deliver the materials in each storage position of the cache master cabinet to the cache sub-cabinet (ESS), and use the shuttle delivery method or the special vehicle delivery method during delivery;

[0030] The shut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com