Low-temperature sterilization equipment

A sterilization equipment, low temperature technology, applied in food preservation, heating preservation of meat/fish, meat/fish preservation and other directions, can solve the problems of untimely temperature adjustment and uneven temperature of sterilized water, saving energy, Conducive to safe production and less loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

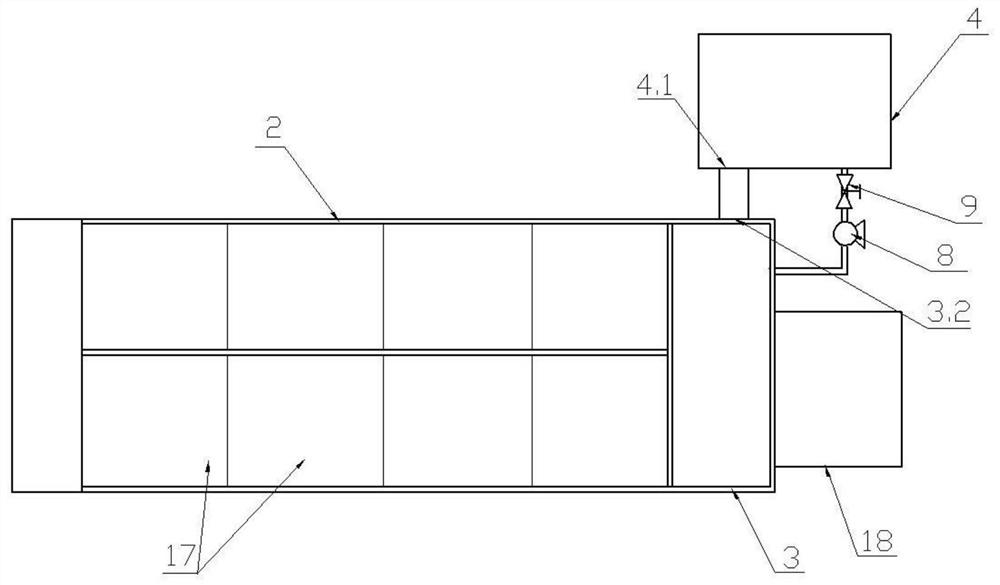

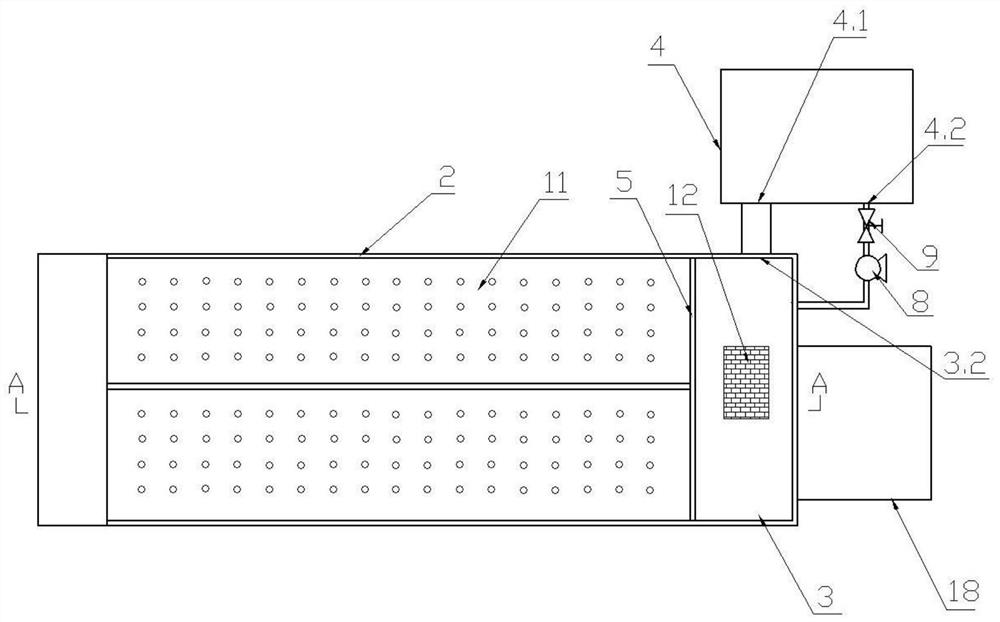

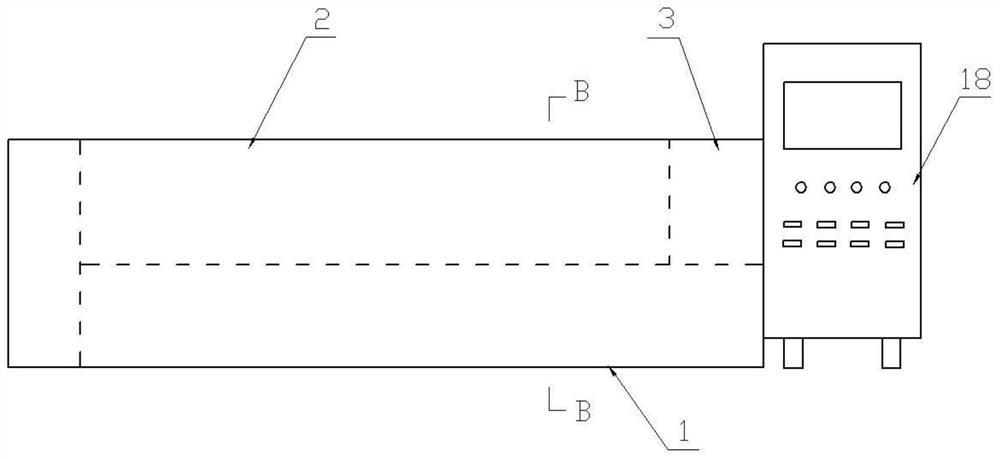

[0042] A low-temperature sterilization equipment, such as Figure 1-6 As shown, including the sterilization equipment body, circulation tank B4 and PLC control system;

[0043] The sterilization equipment body is divided into a heating chamber 1, a sterilization tank 2 and a circulation tank A3; the sterilization tank 2 and the circulation tank A3 are arranged at the upper end of the heating chamber 1; the sterilization tank 2 The upper end of the circulation tank A 3 is open; the sterilization tank 2 and the circulation tank A 3 are separated by an impermeable partition 5, and the upper part of the partition 5 can separate the sterilization tank 2 and the circulation tank A 3 Connected port A 5.1;

[0044] A baffle plate is arranged in the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com