Textile cloth edge sterilizing device

A sterilization device and edge technology, applied in irradiation, disinfection and other directions, can solve problems such as the inability to meet the needs of actual production, and achieve the effect of improving sterilization efficiency and quality and improving sterilization quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

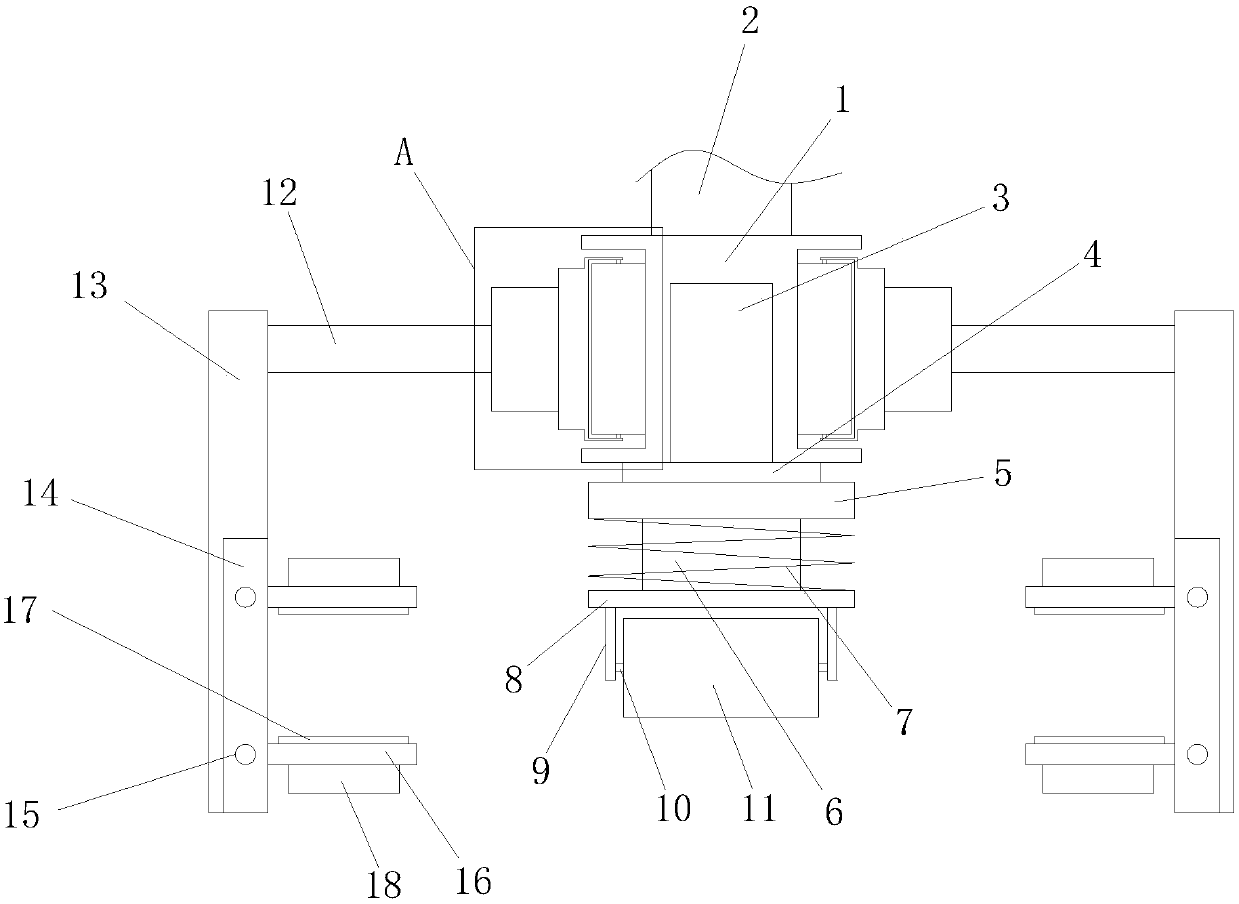

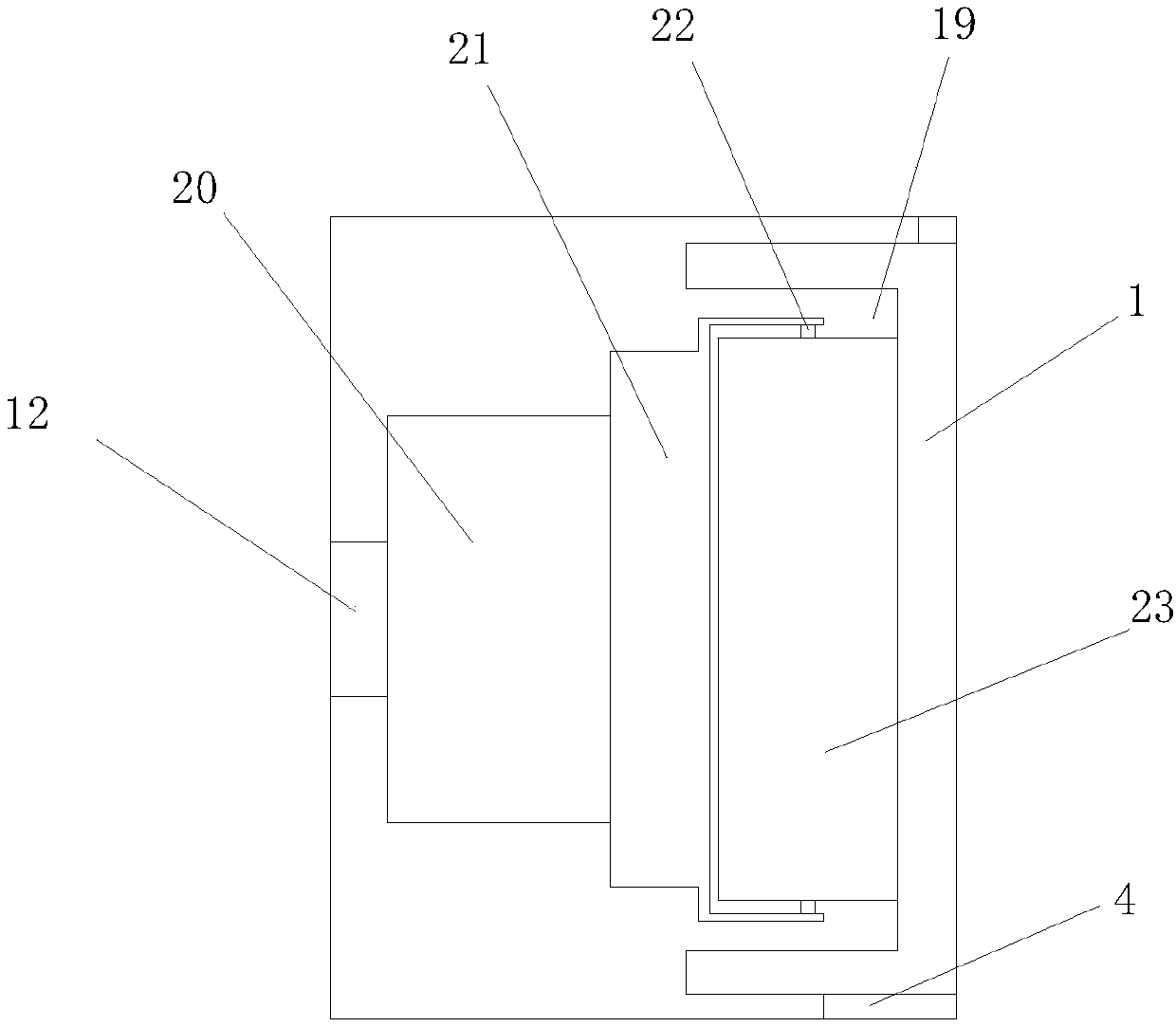

[0015] refer to Figure 1-2 As shown, a kind of textile cloth edge sterilization device proposed by the present invention includes a box body 1, a first installation shaft 2 is installed on the upper end of the box body 1, and limiting grooves 19 are provided on both sides of the box body 1 , the limit groove 19 is provided with a second roller 23, the second roller 23 is installed with a second roller mounting seat 21 through the second rotating shaft 22, and the second roller mounting seat 21 is installed on the side away from the second roller 23 There is a second piston 20, a second piston shaft 12 is installed on the side of the second piston 20 away from the second roller mount 21, and a third installation is installed on the side of the second piston shaft 12 away from the second piston 20. shaft 13, the third installation shaft 13 is provided with a chute 14, a pair of pulleys 15 are installed symmetrically with respect to its center in the chute 14, a slide plate 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com