Microwave continuous sterilization production method for edible mushroom bags

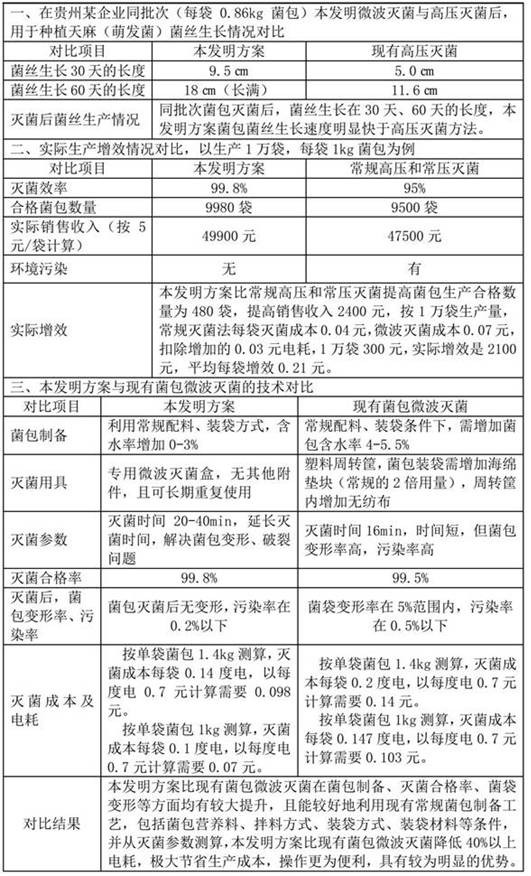

A technology of microwave sterilization and production method, applied in the fields of botanical equipment and methods, application, horticulture, etc., can solve the problems of reducing the scope of application, having no advantages, increasing the cost of sterilization, etc., achieving good heat preservation and moisturizing effect, avoiding Evaporation speed is too fast, the effect of improving sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: (0.5kg specification per bag)

[0022] Step 1, Bacteria bag preparation: Under the conventional bacteria bag preparation process, including the bacteria bag nutrition material, mixing method, bagging method, bagging material and other conditions, the water content of the conventional bacteria bag nutrition material is adjusted to increase by 0-3%, that is The moisture content of the nutrient material in the bacterial bag is increased by 0-3% compared with the conventional bacterial bag preparation process, and the bacterial bag is prepared; The weight of the package is 0.5kg / bag, and the conventional sealing method of plastic cover plus sponge pad or filter cloth is used, and the bacteria package is checked for damage.

[0023] Step 2, Microwave Sterilization: Use a special microwave sterilization box to hold the bacteria package prepared in Step 1. The special microwave sterilization box is composed of a matching box cover with a size of 580×470×150㎜, inside...

Embodiment 2

[0025] Example 2: (1kg specification per bag)

[0026] Step 1, Bacteria bag preparation: Under the conventional bacteria bag preparation process, including the bacteria bag nutrition material, mixing method, bagging method, bagging material and other conditions, the water content of the conventional bacteria bag nutrition material is adjusted to increase by 0-3%, that is The moisture content of the nutrient material in the bacterial bag is 0-3% higher than that of the conventional bacterial bag preparation process, and the bacterial bag is prepared; The weight of the package is 1.0kg / bag, and the conventional sealing method is adopted with a plastic cover and a sponge pad or a filter cloth, and check whether the bacteria package is damaged.

[0027] Step 2, Microwave Sterilization: Use a special microwave sterilization box to hold the bacteria package prepared in Step 1. The special microwave sterilization box is composed of a matching box cover with a size of 580×470×150㎜, in...

Embodiment 3

[0029] Example 3: (2 kg specification per bag)

[0030] Step 1, Bacteria bag preparation: Under the conventional bacteria bag preparation process, including the bacteria bag nutrition material, mixing method, bagging method, bagging material and other conditions, the water content of the conventional bacteria bag nutrition material is adjusted to increase by 0-3%, that is The moisture content of the nutrient material in the bacterial bag is increased by 0-3% compared with the conventional bacterial bag preparation process, and the bacterial bag is prepared; The weight of the package is 2.0kg / bag, and the conventional sealing method is adopted with a plastic cover and a sponge pad or a filter cloth, and check whether the bacteria package is damaged.

[0031] Step 2, Microwave Sterilization: Use a special microwave sterilization box to hold the bacteria package prepared in Step 1. The special microwave sterilization box is composed of a matching box cover with a specification of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com