Automatic dosing tank of ethylene oxide sterilization cabinet

A technology of ethylene oxide sterilizing cabinets and medicine tanks, which is applied in disinfection, construction, water supply equipment, etc., can solve the problems of high cost of medicines, inability to use, and waste of costs, so as to improve the efficiency of dosing, improve the safety of use, and improve the quality of medicines. The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

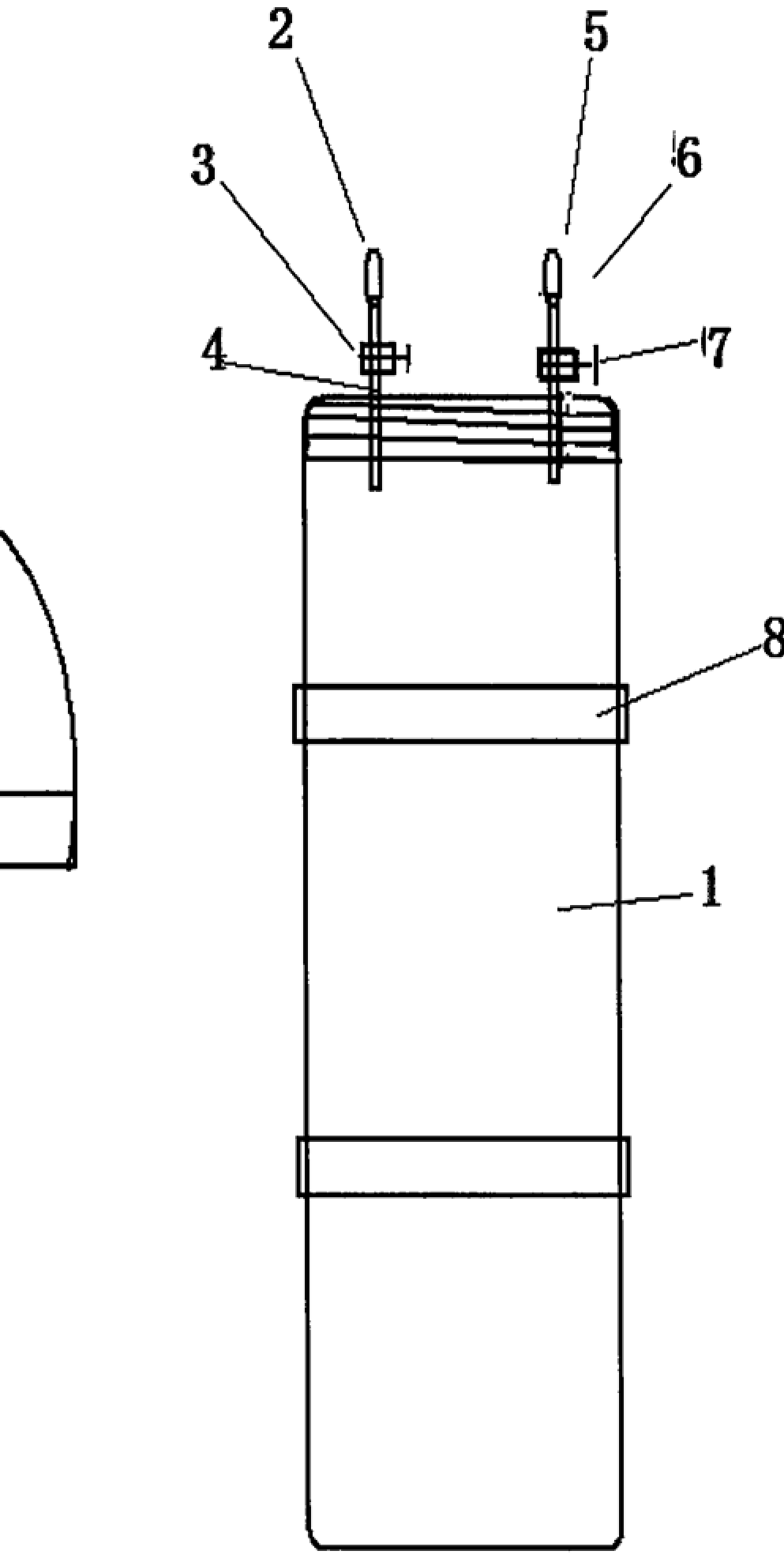

[0009] Specific implementation method: Use medicine tanks of the same specification according to the specifications of the sterilizer, place the medicine tank in the vaporizer of the sterilizer, and connect the self-locking quick-plug connector (female head) of the medicine tank to the medicine inlet of the sterilizer. Connect the self-locking quick-plug connector (male), and then open the injection port valve of the tank. When the operation program of the sterilizer is in the process of dosing (preheating→evacuation→pressure holding→dosing→sterilization), the solenoid valve automatically opens the pneumatic valve of the dosing port of the sterilizer, and the sterilizer is officially connected to the medicine tank. At the same time, the dosing tank of the vaporization device starts to heat up, and the ethylene oxide agent in the medicine tank will vaporize and enter the sterilizer to complete the dosing. After the dosing is completed, the pneumatic valve of the sterilizer is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com