Manufacturing process of fresh flower skirt and fresh flower skirt

A technology for making flowers and flowers, which is applied in the field of clothing, can solve the problems of long production process of flower skirts, etc., and achieve the effects of shortening the production time, convenient installation and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

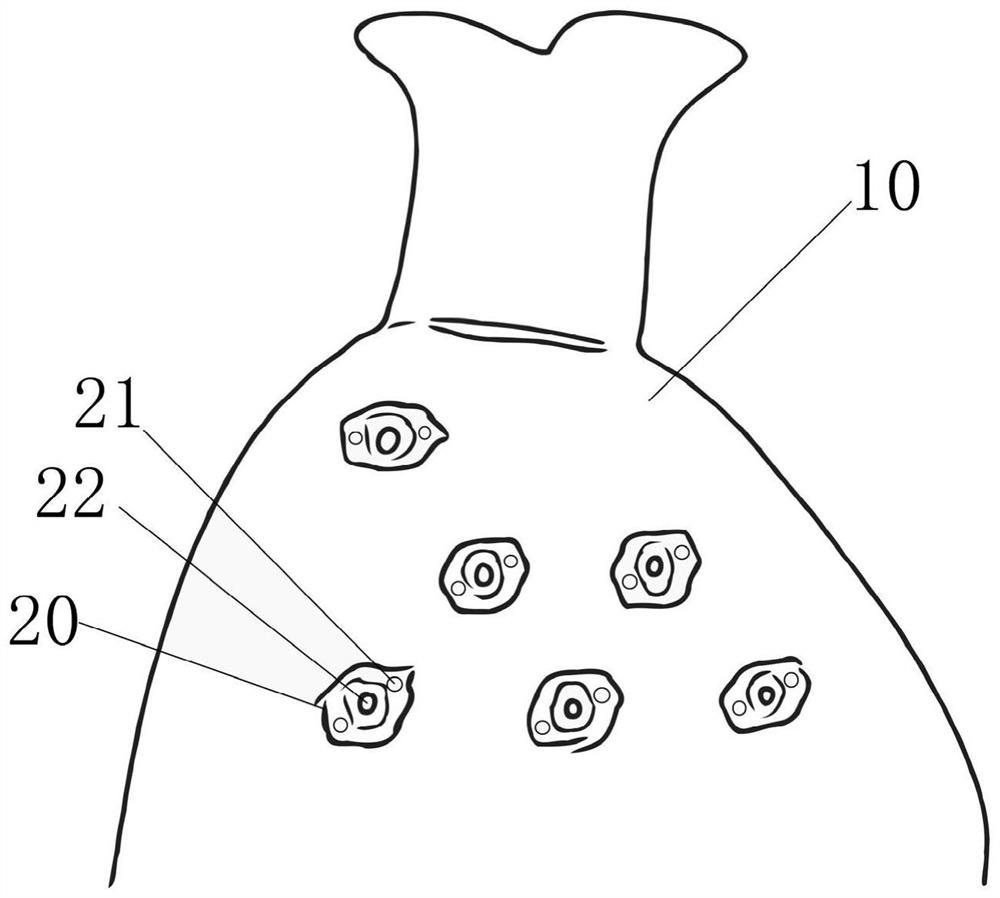

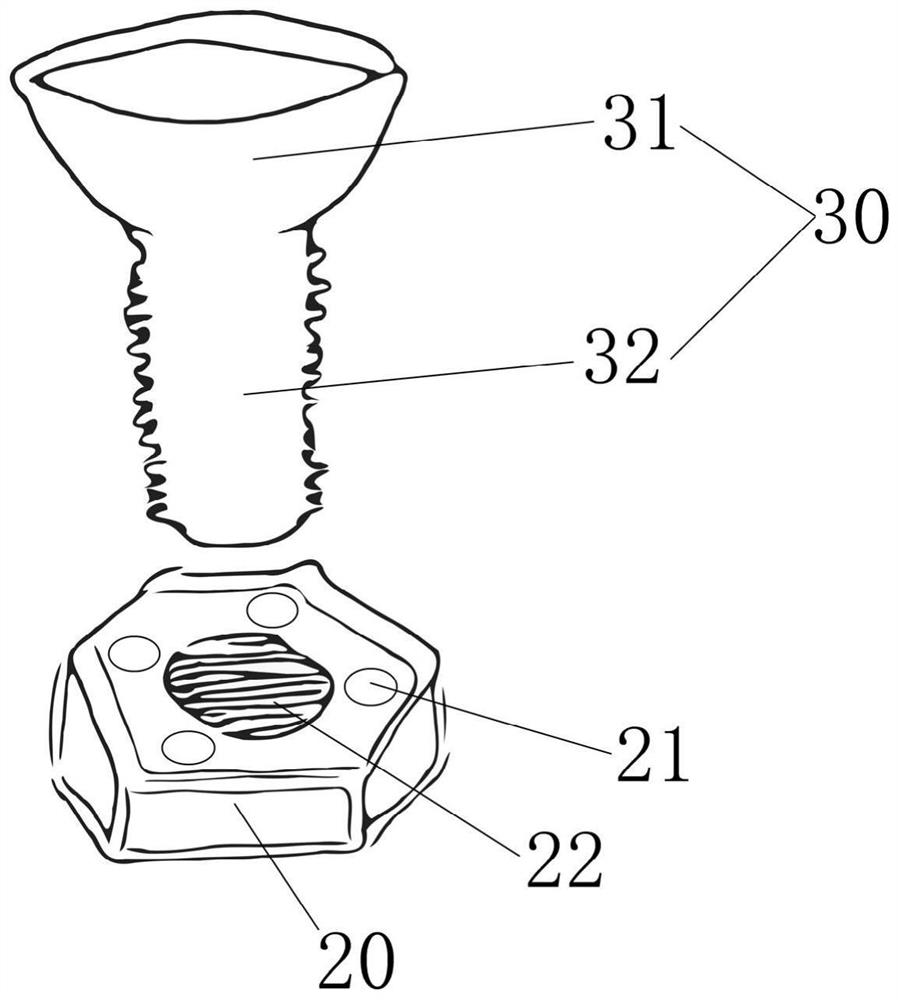

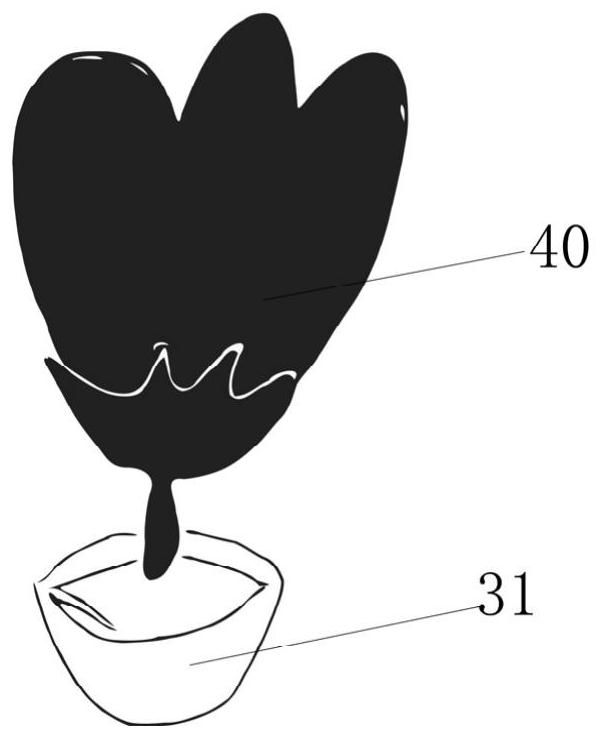

[0021] Flower skirts can be used as wedding dresses, evening dresses, etc., to be worn on similar occasions. In the prior art, such as a rose skirt, more than 1,700 flowers are needed, and the whole production process is purely handmade, which takes 170 hours. Therefore, the cost of man-hours is relatively high. The reason why it needs such a long time is that the existing flower skirt adopts flower arrangement mud, and the flower arrangement mud is a kind of flower arrangement article made by phenolic plastic foaming. Like flower sockets, it is a special tool for fixing and supporting flower materials. It is shaped like a rectangular brick, as light as foam plastic, and as heavy as lead after absorbing water. open it. Although this kind of flower arrangement mud is commonly used, it is not easy to fix it on flower skirts. Usual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com