Integrated type frame light aircraft

An all-in-one, aircraft technology, applied in the field of aircraft, can solve the problems of lack of storage space, large aircraft mass, and large occupied space, and achieve the effect of changing the manufacturing process, improving the cargo capacity, and increasing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as Figure 1 to Figure 3 Shown, a kind of unibody frame lightweight aircraft, including fuselage, nose, tail and wings.

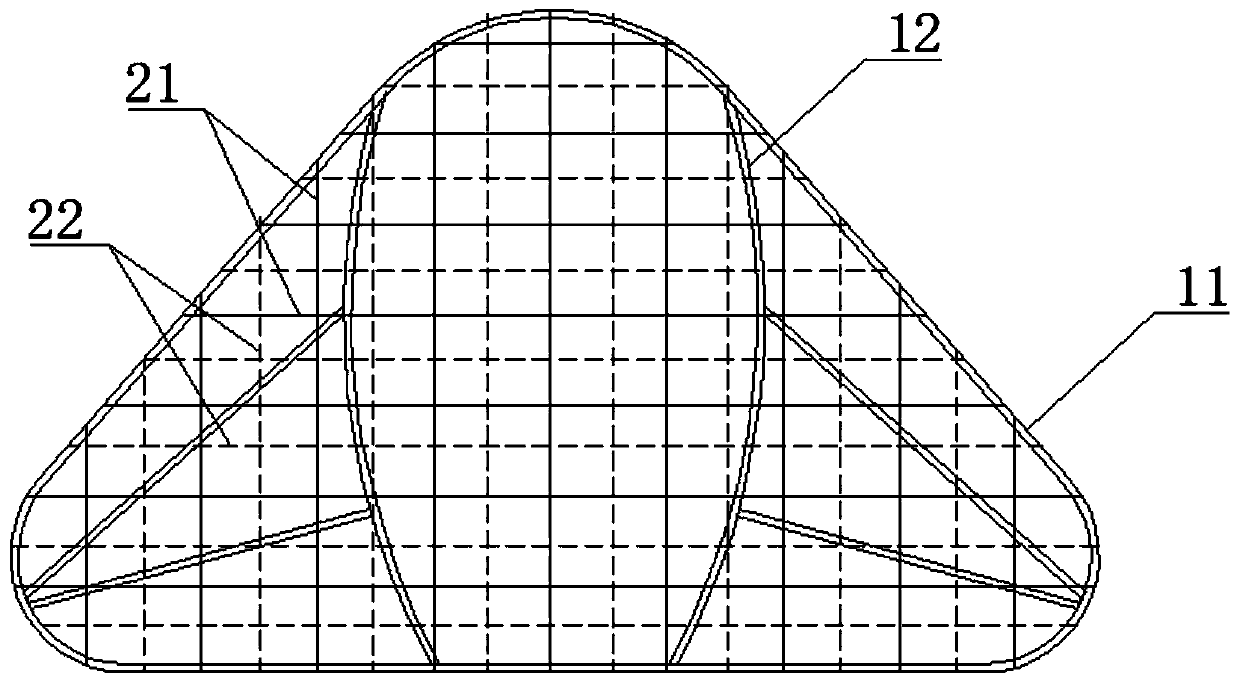

[0030] The aircraft in the present embodiment is an aircraft, comprising an integral frame 1, and the integral frame 1 is integrally formed by a wing frame 11 and a fuselage frame 12;

[0031] There are a plurality of main steel cables 21 wound on the outside of the integrated frame 1, and the main steel cables 21 form a supporting mesh surface outside the integrated frame 1, and a plurality of auxiliary steel cables 22 are also arranged between the main steel cables 21, so that the supporting mesh surface more detailed. In order to reduce aircraft weight and reduce material consumption, the auxiliary steel cable 22 should be thinner than the main steel cable 21.

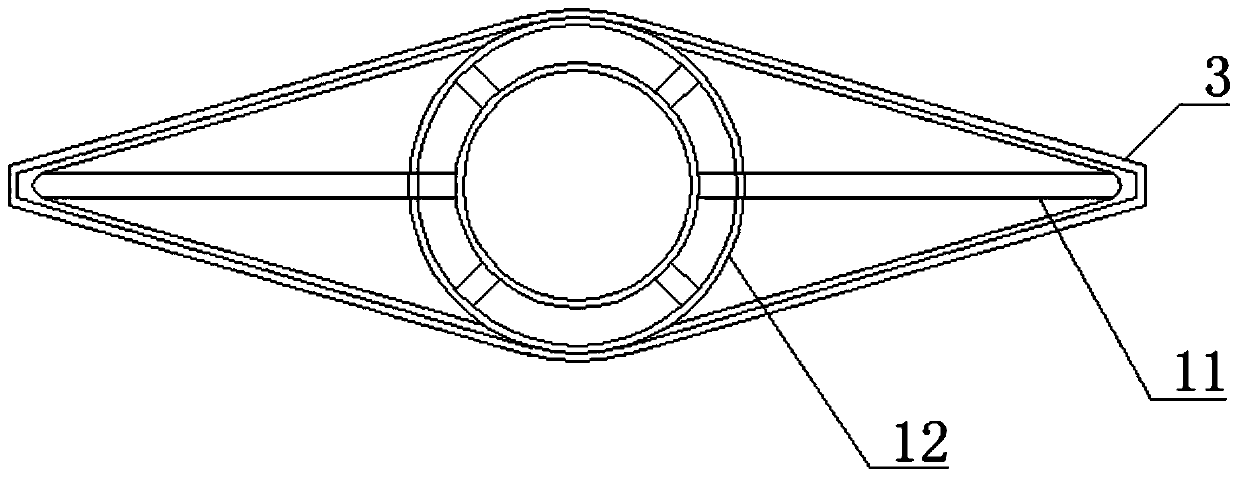

[0032] An outer protective layer 3 of flexible material is arranged on the supporting net surface. Preferably, the outer protective layer 3 is a flexible plate formed by laminating ...

Embodiment 2

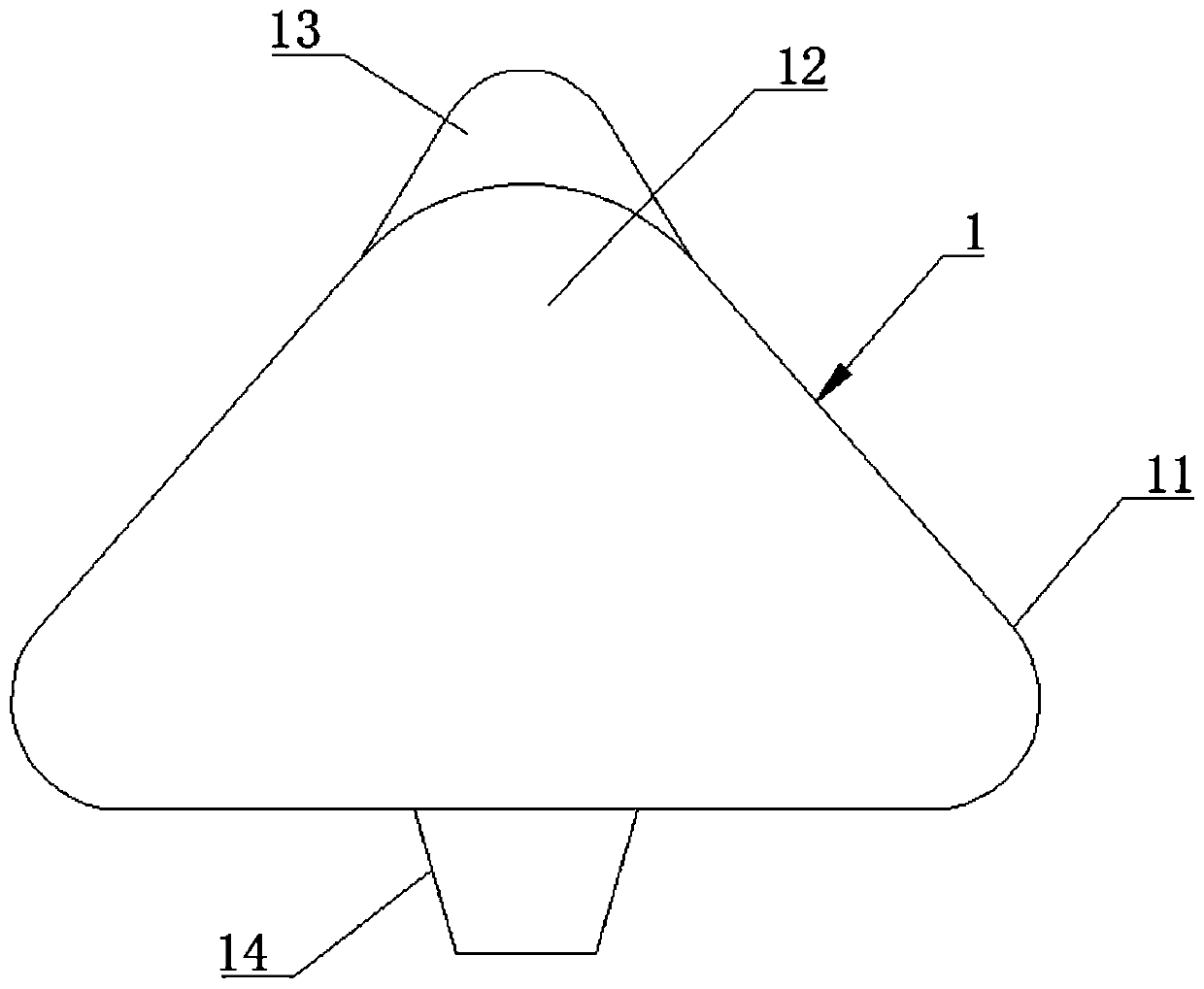

[0042] Such as Figure 4 to Figure 6 As shown, in this embodiment, the aircraft includes a one-piece frame 1 , and the one-piece frame 1 is integrally formed by a fuselage frame 12 , a nose frame 13 and a tail frame 14 .

[0043] The main steel cable 21 and the auxiliary steel cable 22 are wound on the outside of the integrated frame 1, and an outer protective layer 3 is installed on the outside. Mounting ports connected to the wing frame 11 are reserved on both sides of the integrated frame 1, and the wing frame 11 is tightened through the The parts are installed on the installation port.

[0044] A cabin is formed inside the wing frame 11 , and the main steel cables 21 and auxiliary steel cables 22 are also wound around the outside of the wing frame 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com