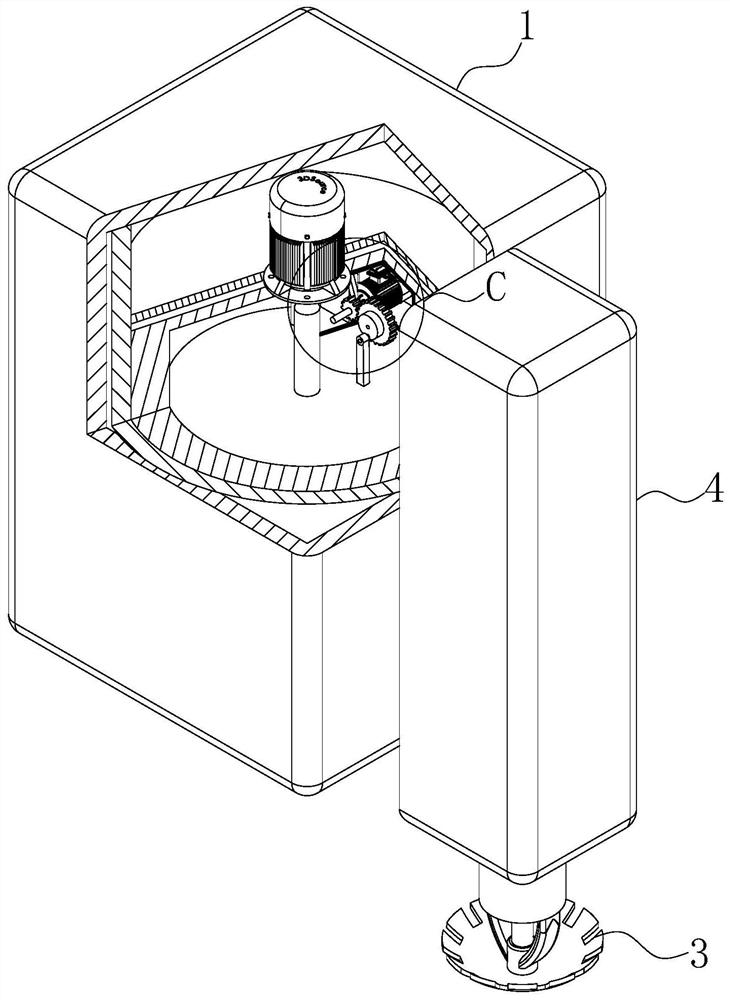

Automatic spraying equipment with high-sensitivity gas sensing function

A high-sensitivity, automatic spraying technology, applied to fire alarms and fire rescues that rely on smoke/gas effects, can solve problems such as low smoke concentration, low smoke concentration, difficulty in satisfying rapid fire warning, etc., and achieve rapid alarm , The effect of improving the detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

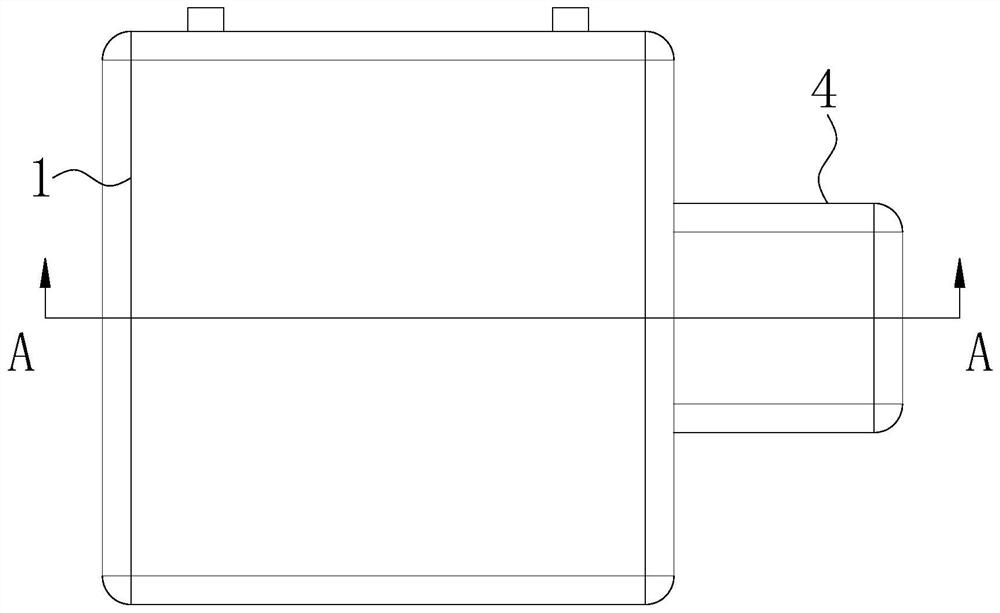

Method used

Image

Examples

Embodiment approach

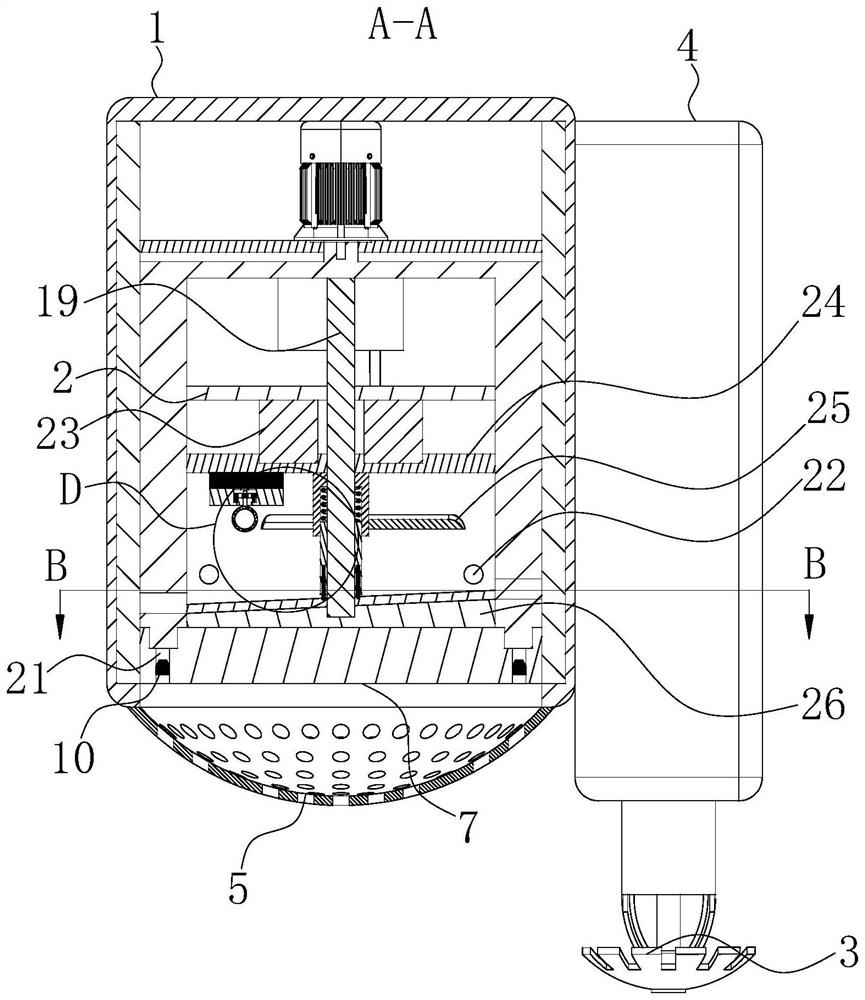

[0028] As an embodiment of the present invention, the lower surface of the sealing plate 7 is provided with a first guide hole 21; the number of the first guide holes 21 is two, and they are arranged symmetrically; the two first guide holes The inside of 21 is all fixedly connected to the check valve 10; the lower surface of the rotating block 8 is provided with a second guide hole 22 near the first guide hole 21; during work, the first guide hole is opened on the surface of the sealing plate 7 21. At the same time, a second guide hole 22 is provided on the surface of the rotating block 8. When the first motor 9 rotates, the first motor 9 will drive the rotating block 8 to rotate, and the second guide hole 22 and the corresponding second guide hole 22 will be realized by rotating the rotating block 8. The automatic conduction and automatic disconnection between a guide hole 21 realizes the automatic conduction between the cylinder tank and the external environment and the fast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com